Sorry to say it will not.....unfortunately, I have been buried in business dealings all this week & have barely touched it!

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ultimate Hybrid NSX Project

- Thread starter LS7NSX

- Start date

Hey Dale I need some pictures! If you don't have any you need to get back to work. :biggrin:

Just google "aluminum plate holes drilled" and hit images. It's what I do when I have withdrawal symptoms.

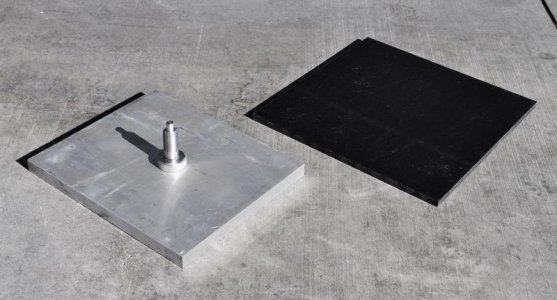

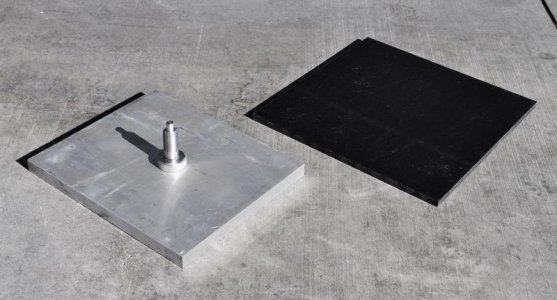

Swing-away steering

Spent some "head-scratching time" figuring out how to make entrance & exit easier, since the steering wheel placement is relatively close to my chest. The chrome knob is a spring-loaded plunger that you pull & twist to disengage from the "ramp". Black parts are a hi-strength Delrin for smooth motion between full up, and full down. The column swings up & to the right, with a positive detent at the end of its travel (picture ramp angled approx 45 degrees).

Spent some "head-scratching time" figuring out how to make entrance & exit easier, since the steering wheel placement is relatively close to my chest. The chrome knob is a spring-loaded plunger that you pull & twist to disengage from the "ramp". Black parts are a hi-strength Delrin for smooth motion between full up, and full down. The column swings up & to the right, with a positive detent at the end of its travel (picture ramp angled approx 45 degrees).

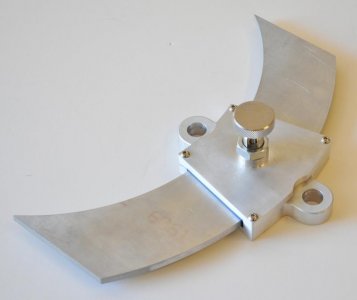

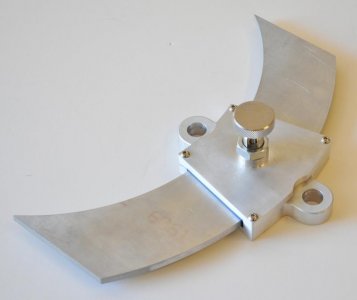

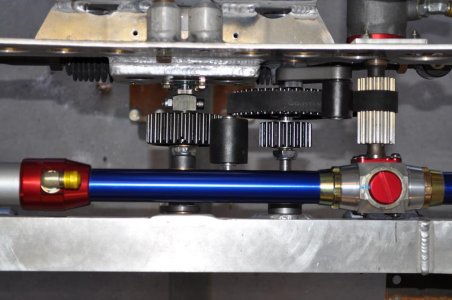

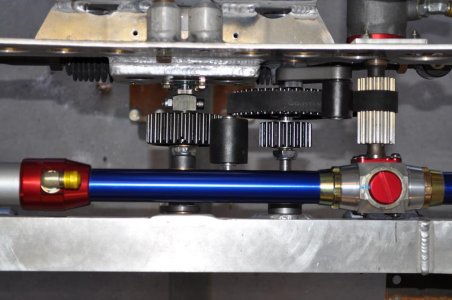

Mini Rack Countershaft

So I was doing some assembling today, & amazed myself with the complexity of such a simple design......15 separate pieces, 6 of them scratch-built, just to have a countershaft for my steering / suspension system! The challenge was; "how do you make a shaft supported by bearings on both ends fit between 2 fixed crossmembers, & still allow for installation & removal (as in belt change)"?

Will upload some "installed" pics tomorrow!

Well it's now tomorrow, so here's the latest.

So I was doing some assembling today, & amazed myself with the complexity of such a simple design......15 separate pieces, 6 of them scratch-built, just to have a countershaft for my steering / suspension system! The challenge was; "how do you make a shaft supported by bearings on both ends fit between 2 fixed crossmembers, & still allow for installation & removal (as in belt change)"?

Will upload some "installed" pics tomorrow!

Well it's now tomorrow, so here's the latest.

Last edited:

That's just an amazing project. I'm speechless.

This should be a TV series.

Dave

This should be a TV series.

Dave

So what is with the numerous gears for the mini (powersteering?) rack..? To underdrive it? Response? How exactly does it work between suspension and steering?

Amazed at the level of craftsmanship as always.

The picture is missing 1 belt. The power steering servo drives both the Woodward Power rack (real pretty part) and the mini-rack (not power). The mini rack moves the lower control arm pickups right or left to effect a change in camber proportional to the degree of steering input. The countershaft & pulleys are designed to allow for adjusting the aggressiveness of the camber shift. I'm working on an oblong pulley that will result in the camber shift being non-linear, as in accelerate as it recieves uniform rotational input from the servo (all of the HTD pulley manufacturers think I'm nuts!).

Now don't tell anyone about this because my patent is still only "pending", & I might have to send my Uncle Guido to visit anyone trying to steal my design. Same for my swing-away steering "glide".

That's just an amazing project. I'm speechless.

This should be a TV series.

Dave

Thanks for the compliment!......sometimes I'm speechless too, but it's really just the result of thinking too hard! Working on the racecar is the best therapy.....I can spend hours just thinking about ways to "do it better"!

I was wondering how you were going incorporate the camber adjustments. I am still curious though if while in turn and need to make major adjustments during turn, will the changing of camber during that turn upset the traction and/or car too much? And what about toe?The picture is missing 1 belt. The power steering servo drives both the Woodward Power rack (real pretty part) and the mini-rack (not power). The mini rack moves the lower control arm pickups right or left to effect a change in camber proportional to the degree of steering input. The countershaft & pulleys are designed to allow for adjusting the aggressiveness of the camber shift. I'm working on an oblong pulley that will result in the camber shift being non-linear, as in accelerate as it recieves uniform rotational input from the servo (all of the HTD pulley manufacturers think I'm nuts!).

Now don't tell anyone about this because my patent is still only "pending", & I might have to send my Uncle Guido to visit anyone trying to steal my design. Same for my swing-away steering "glide".

It is an amazing design none the less.

I was wondering how you were going incorporate the camber adjustments. I am still curious though if while in turn and need to make major adjustments during turn, will the changing of camber during that turn upset the traction and/or car too much? And what about toe?

It is an amazing design none the less.

Thanks,....actually I contemplate the same thing....the only mitigating factor is that the total steering in either direction is only 20 degrees (FAT tires!), & the total amount of caster "shift" is relatively small (about 2-3 degrees) at about 50% turn-in. If I discover that is too much "attack", I can change the pulley ratios by only changing out ONE pulley.....likewise if I feel there's not enough attack through a "normal" turn-in input, I can adjust for more aggresive camber shift.

The toe-in shouldnt change at all because the lower control arm pivot points are moving the SAME direction...either right or left. Picture a parallelogram where toe is measured at the center of both sides, no matter which way you slant the sides.

Happy New Year to all of you following my obsession!

Last edited:

Happy New Year brother....!

Happy New Year to all of you following my obsession!

Starting to look like a racecar!

Spent about 3 days digging out all of my suspension "stuff" (picture a 7-car garage with boxes floor to ceiling) after spending the first 6 weeks of the year moving into my new home (Horsepower Ranch). Leave it to the powdercoaters to not properly mask the bearing "cups" on the shock rockers, and the monoball cups on the control arms.....had to de-burr & sand ALL just to be able to insert the ball bearings & monoballs......AND, had to drill every shock mount & pushrod hole thru to clean the powdercoat out of the bolt bores! About 6 hrs of prep just to be able to loctite everything together before assembly!

The pictures show the suspension @ full "droop"......discovered I will have to do a little chopping of the upper part of engine bay surround at the furthest aft point, just to clear the rear tires @ full compression....but not a structurually significant mod at all.....should be no match for my 8" grinder & cut-off wheel!

I hope to finish the front corners by this weekend so I can set the car down & calculate the final lengths for the 4 pushrods. A close look at the area between the shock rocker & inside edge of rear tire will better illustrate why the pushrod design is so much more sanitary than trying to stuff a shock in the OEM location.......besides, it makes set-up a whole lot easier when the shocks are easy to get to (also lower COG!).

I've also been tidying up the fuel cell surrounds, & just finished fabricating a smooth "floor" to the tunnel where the radiator & oil lines exit the engine bay & route to the front of the car (lower-center of pic)......a whole lotta late-night pattern making going on at "the ranch"!

Will post new pics when front corners are hung.

Spent about 3 days digging out all of my suspension "stuff" (picture a 7-car garage with boxes floor to ceiling) after spending the first 6 weeks of the year moving into my new home (Horsepower Ranch). Leave it to the powdercoaters to not properly mask the bearing "cups" on the shock rockers, and the monoball cups on the control arms.....had to de-burr & sand ALL just to be able to insert the ball bearings & monoballs......AND, had to drill every shock mount & pushrod hole thru to clean the powdercoat out of the bolt bores! About 6 hrs of prep just to be able to loctite everything together before assembly!

The pictures show the suspension @ full "droop"......discovered I will have to do a little chopping of the upper part of engine bay surround at the furthest aft point, just to clear the rear tires @ full compression....but not a structurually significant mod at all.....should be no match for my 8" grinder & cut-off wheel!

I hope to finish the front corners by this weekend so I can set the car down & calculate the final lengths for the 4 pushrods. A close look at the area between the shock rocker & inside edge of rear tire will better illustrate why the pushrod design is so much more sanitary than trying to stuff a shock in the OEM location.......besides, it makes set-up a whole lot easier when the shocks are easy to get to (also lower COG!).

I've also been tidying up the fuel cell surrounds, & just finished fabricating a smooth "floor" to the tunnel where the radiator & oil lines exit the engine bay & route to the front of the car (lower-center of pic)......a whole lotta late-night pattern making going on at "the ranch"!

Will post new pics when front corners are hung.

I just have one question....are you going to be able to clear the medical exam to drive it when it's finished or you planning on running the senior citizens vintage races ?

LOL....I owe you a beer for that one...but couldn't resist.

Where are you classing it ?

Awesome is all I can say..

LOL....I owe you a beer for that one...but couldn't resist.

Where are you classing it ?

Awesome is all I can say..

Starting to look like a racecar!

Spent about 3 days digging out all of my suspension "stuff" (picture a 7-car garage with boxes floor to ceiling) after spending the first 6 weeks of the year moving into my new home (Horsepower Ranch). Leave it to the powdercoaters to not properly mask the bearing "cups" on the shock rockers, and the monoball cups on the control arms.....had to de-burr & sand ALL just to be able to insert the ball bearings & monoballs......AND, had to drill every shock mount & pushrod hole thru to clean the powdercoat out of the bolt bores! About 6 hrs of prep just to be able to loctite everything together before assembly!

The pictures show the suspension @ full "droop"......discovered I will have to do a little chopping of the upper part of engine bay surround at the furthest aft point, just to clear the rear tires @ full compression....but not a structurually significant mod at all.....should be no match for my 8" grinder & cut-off wheel!

I hope to finish the front corners by this weekend so I can set the car down & calculate the final lengths for the 4 pushrods. A close look at the area between the shock rocker & inside edge of rear tire will better illustrate why the pushrod design is so much more sanitary than trying to stuff a shock in the OEM location.......besides, it makes set-up a whole lot easier when the shocks are easy to get to (also lower COG!).

View attachment 84357

View attachment 84358

I've also been tidying up the fuel cell surrounds, & just finished fabricating a smooth "floor" to the tunnel where the radiator & oil lines exit the engine bay & route to the front of the car (lower-center of pic)......a whole lotta late-night pattern making going on at "the ranch"!

View attachment 84359

Will post new pics when front corners are hung.

Last edited:

Medical exam?.......we don't need no steenking medical exam!!

Actually, today marks the 1 year anniversary of me working out 3-4 days/week.......specifically designed (by my fitness & nutrition guru, Ray Florio) so I have the strength & endurance necessary to compete at this level.

I even dusted off the shifter, & spent an entire day @ PKRA with another "duffer" friend of mine, Mike Duncan (who has raced NSXs all over Europe).

The car is designed to run in GT-1 in the NARRA events, and Unlimited in everyone else's.

Actually, today marks the 1 year anniversary of me working out 3-4 days/week.......specifically designed (by my fitness & nutrition guru, Ray Florio) so I have the strength & endurance necessary to compete at this level.

I even dusted off the shifter, & spent an entire day @ PKRA with another "duffer" friend of mine, Mike Duncan (who has raced NSXs all over Europe).

The car is designed to run in GT-1 in the NARRA events, and Unlimited in everyone else's.

LOL....

I can't wait to see it run Dale.

Amazing job you're doing on it.

I can't wait to see it run Dale.

Amazing job you're doing on it.

Medical exam?.......we don't need no steenking medical exam!!

Actually, today marks the 1 year anniversary of me working out 3-4 days/week.......specifically designed (by my fitness & nutrition guru, Ray Florio) so I have the strength & endurance necessary to compete at this level.

I even dusted off the shifter, & spent an entire day @ PKRA with another "duffer" friend of mine, Mike Duncan (who has raced NSXs all over Europe).

The car is designed to run in GT-1 in the NARRA events, and Unlimited in everyone else's.

Tire Clearance Remedy

These pics are with wheel & tire @ static ride height, & reveal only about a 1/4" clearance at the top edge of tire.....have to allow for another 2.5" of suspension compression, SO.......

Now I just have to dress the edges, roll a piece of .090" 5052 (forms nicer than 6061) thru the 'ol English wheel, & have my TIG artist make it look like spacecraft!

These pics are with wheel & tire @ static ride height, & reveal only about a 1/4" clearance at the top edge of tire.....have to allow for another 2.5" of suspension compression, SO.......

Now I just have to dress the edges, roll a piece of .090" 5052 (forms nicer than 6061) thru the 'ol English wheel, & have my TIG artist make it look like spacecraft!

Last edited:

How did I miss this thread? This is absolutely incredible! I'm speechless Dale and anyone who knows me will tell you that is quite the accomplishment! :biggrin:

Its coming together! Looking great, I always look forward to updates on this thread.:biggrin:

If you do not work for a F1 race shop or chief engineer for a automaker, you should.

Similar threads

- Replies

- 24

- Views

- 7K

- Replies

- 0

- Views

- 1K