Got the car back from the shop, and it was a disaster. As [MENTION=12356]Mac Attack[/MENTION] predicted, the cost ballooned and ended up being 70-80% higher than initially expected. Suspension ball joint taper fittings were seized together and the shop was not willing to go the popular aftermarket ball joint replacement route due to the turnaround time so I was forced to replace about $1500 worth of OEM suspension components. This alone I don't really have a problem with, its 25 years old, stuff gets stuck, I understand that it's not feasible to have a car taking up a bay for weeks on end waiting for parts. However, a day or so after picking the car up I noticed a rather severe valve cover gasket oil leak dripping right onto the exhaust and I had brand new OEM valve cover kits put on.

There is absolutely no excuse for a valve cover gasket to leak if the engine is out of the car while the work is being performed, it is ridiculously easy to see everything and to clean everything before installation. As far as I can tell the tech was just lazy and didn't clean the sealing surfaces properly.

Also, the cam plugs have gobs and gobs of Hondabond around them, you are not caulking your shower, you don't need that much sealant. Frankly, I will be surprised if I don't have to pull the engine myself and replace a bunch of seals that I just had replaced because they were installed improperly.

And there's lots of valvetrain noise now, apparently they didn't bother to do a valve adjustment after pulling the cams, it's almost like they just threw the lifter assemblies back in wherever without bothering to make sure they went back to the same place or even checking the clearance.

I redid the valve cover and the leak appears to be gone, but it looks like sometime soon I will have to do it again and adjust the valves.

Anyways, lesson learned.

--------------------------------------------------------------------------------------------------------------------------------------------

After taking my headlights apart in July expecting a quick week or two project, I finally finished my HID retrofit 4 months later.

The most time consuming part of this was the wiring. At first I was just going to tweak the factory headlight harnesses a bit and install the ballasts behind the light assemblies. That didn't end up working out though because the factory wiring is old and fairly high resistance, and the ballasts wouldn't reliably ignite the bulbs using that setup. I bought the OrganizedGarageStatus kit that included the Morimoto projectors, projector brackets, and clear lenses.

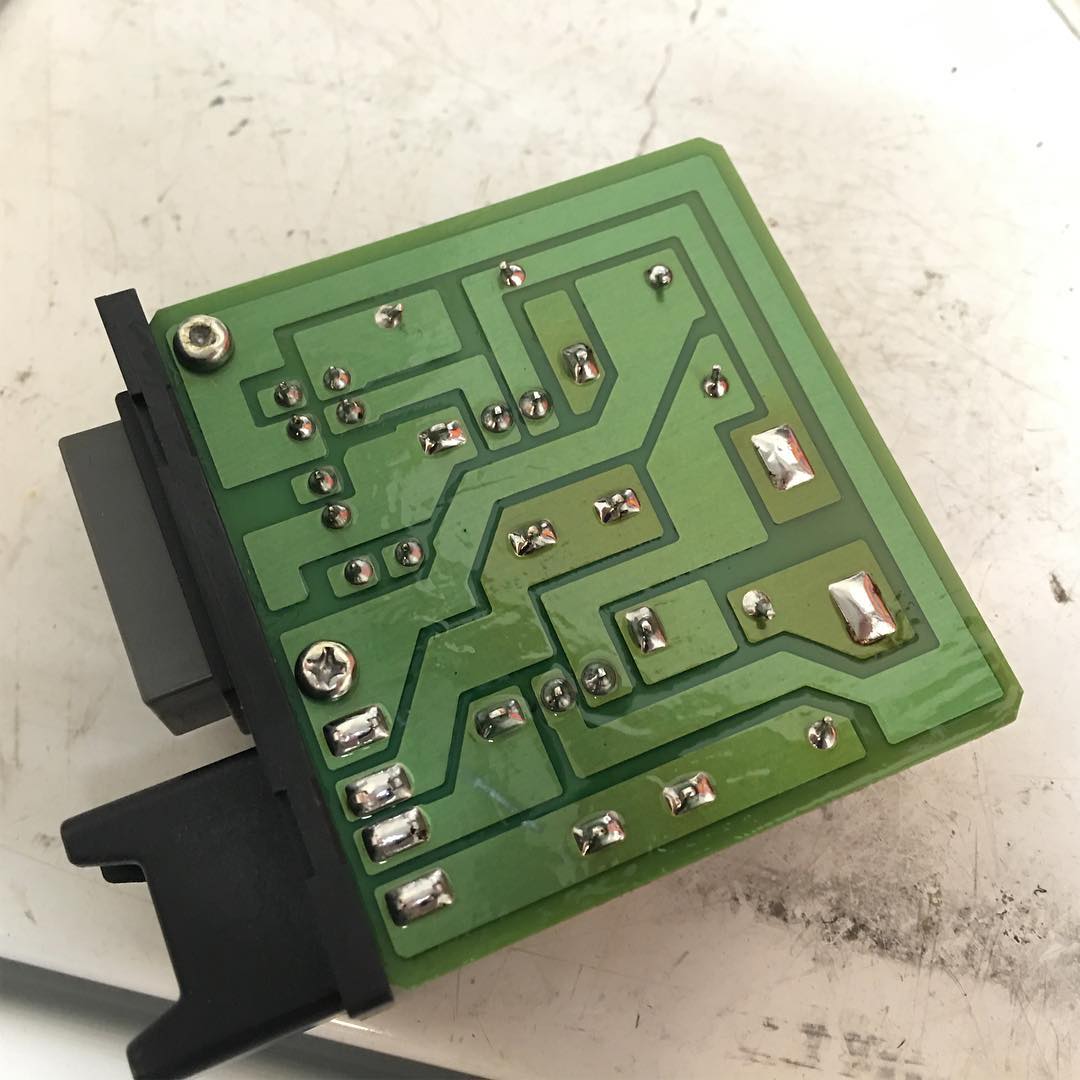

The ballasts I'm using are the tried and true Hella gen 3 found in many many cars over the past 20ish years. They're easy to find, relatively cheap, 100% weatherproof, and very reliable. They typically come with D2S connectors but I cut them off and soldered on AMP connectors to run them with the Morimoto H1 bulbs, then sealed the connection using adhesive-lined heat shrink tubing. This is the first iteration with very short wires, along the way I redid the solders with longer wires when I changed the ballast mounting position.

This was my first ballast mounting solution: zip ties. I wasn't happy with this either, which was another factor in my scrapping of this method.

First headlight wire harness, it was a modified factory harness.

I didn't like it so I made my own from scratch after sourcing the factory plug components, but the 9005 plugs I bought didn't fit in the NSX housing so these were scrapped too, and I ended up reusing the original NSX plugs.

Unfortunately I don't have pictures of the final headlight harness, but rather than a 9006 plug coming out the back for the ballast, it had a smaller waterproof connector that goes to a relay that controls the ballast. I made these (not particularly pretty) ballast and relay brackets from aluminum.

Passenger side mounted.

Driver side mounted.

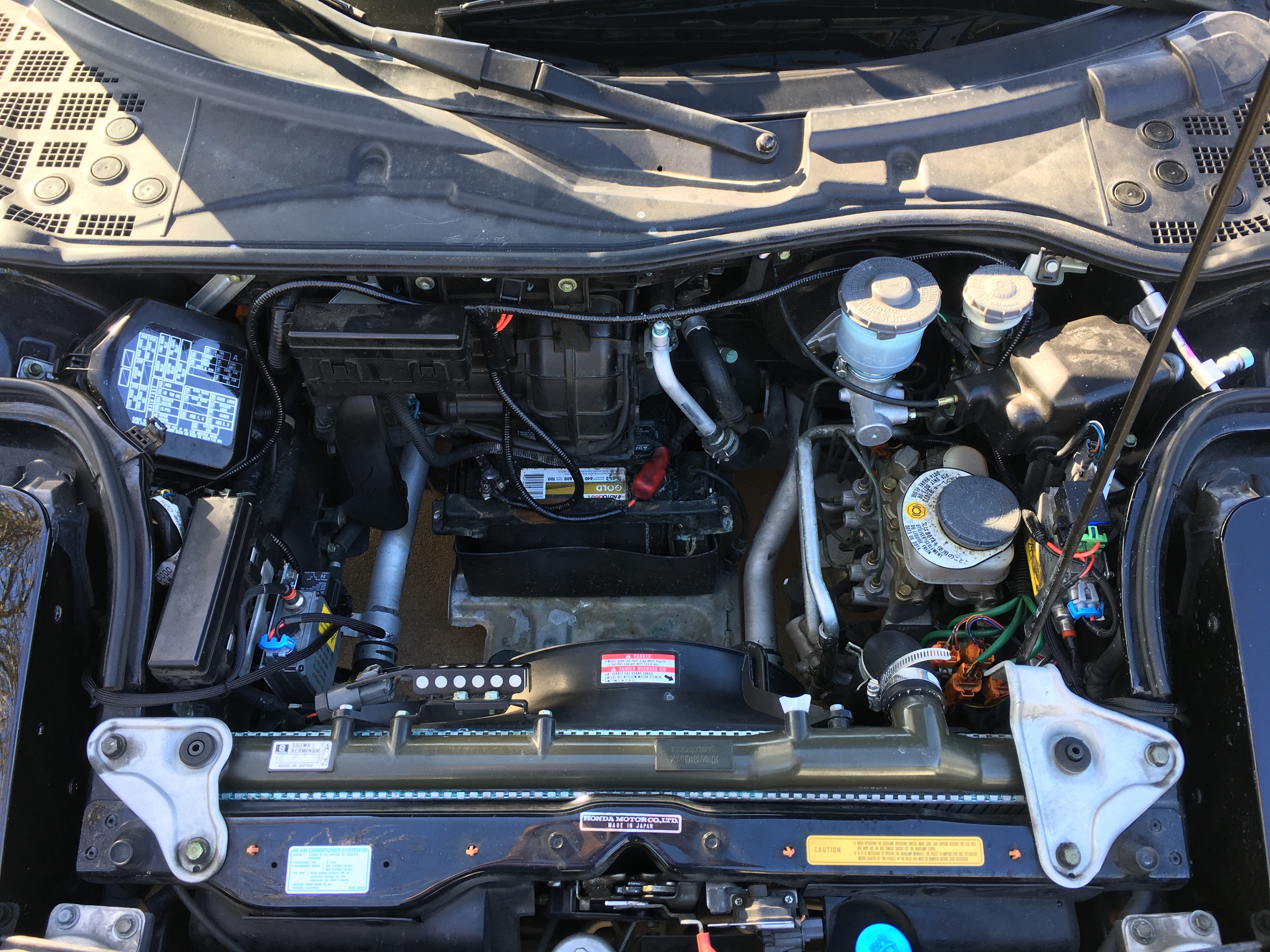

Everything wired up. I didn't want to drill anything or poke holes in grommets so I ran the ballast turn-on signal and the HID bulb wires in front of the headlight weather seal, then zip-tied it to the factory harness that allows the lights to go up and down, then finally into the connectors at the back of the lights.

(I forgot to upload the picture here I'll do it in a little while)

To align the lights, I built this rudimentary jig to hold the lights perfectly horizontal while I set the alignment of the HID projects and high beam projectors.

Test wiring setup: the car battery with a 9006 and 9005 plug.

Headlights installed.

The output is absolutely amazing, it blows away any of the drop in HID solutions, like absolutely no comparison whatsoever. The OrganizedGarageStatus clear lenses, while pricey, make a huge difference as well, the factory glass lenses distort the output too much and lose clarity as they chip over time.