- Joined

- 2 February 2024

- Messages

- 27

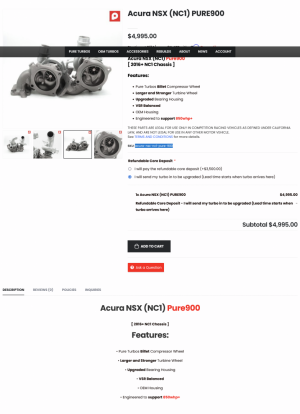

No thread on it yet but Pure Turbos announced their Pure900 upgrade for the NSX which they say is 850+ whp capable: https://www.pureturbos.com/product/acura-nsx-nc1-pure-900/

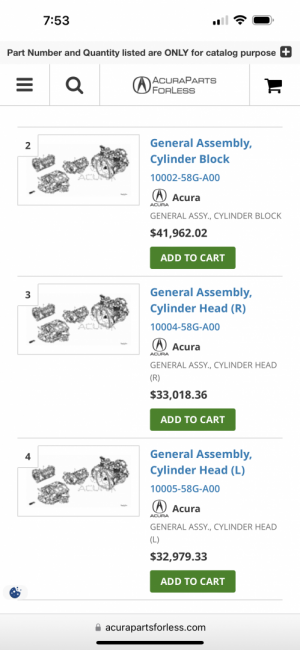

I mean just look at the difference:

This should be exactly what the NSX needs assuming the tuning is there. The fuel system shouldn't have any problem as the port side should be able to handle things or even be upgraded for E85 I would think.

The transmission on the other hand...

I mean just look at the difference:

This should be exactly what the NSX needs assuming the tuning is there. The fuel system shouldn't have any problem as the port side should be able to handle things or even be upgraded for E85 I would think.

The transmission on the other hand...