amazing! I love your attention to detail

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New owner. Mini fix it / build thread

- Thread starter Tech7042

- Start date

16th any update?

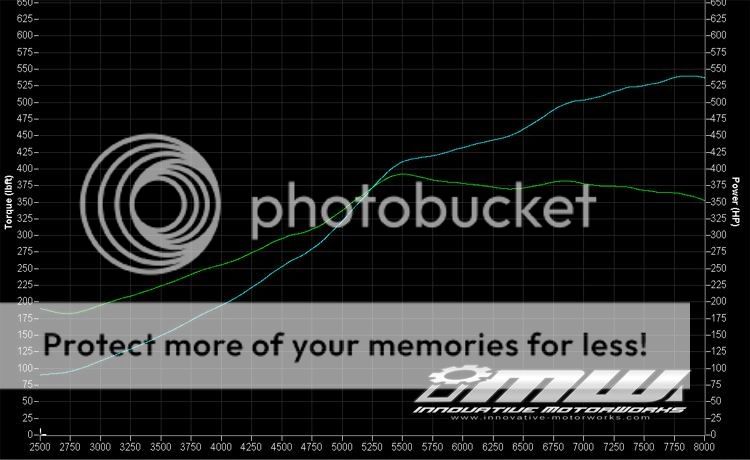

Went tuning yesterday. Good news is I hit my E85 goal of 550 whp on pump gas. Bad news is there is massive boost creep and the clutch slipped on the dyno.

With a 10lb spring installed in the wastegate, the boost creeped up to 15psi. On the first run we saw 502whp and 405tq. This is when the clutch slipped. The amazing thing is that I am spooling a LOT quicker now. We compared my previous boost graph with the new one and I'm hitting the same amount of boost (8psi) 2000rpm earlier. On this setup, I hit the wastegate spring value of 10psi at 4600RPM, and then spiked up to 15.

We tried to control the creep by swapping wastegate springs for a 5lb. We were able to get one run in, as it creeped up to 10psi, and yielded around the same power and tq at redline. We tried another run after a few things were adjusted in the tune, and it creeped again up to 15psi. This is when we saw 550whp / 420tq at 7000RPM. If there was no boost creep, and no clutch slippage- I think we would have seen high 500's on a complete pull.

We determined that the reason for the boost creep is poor wastegate placement and routing. On my y-pipe, there is an elbow with a flange that connects to the wg. The elbow is a small diameter pipe facing the wrong way (against the stream of exhaust flow). Because of this, the exhaust pressure can't be relieved quick enough when the wastegate opens- causing creep. I am going to send IMW my y-pipe and they are going to modify it by cutting off the elbow, and replacing it with a larger diameter pipe that is short and faces the correct direction. This should solve the creep issue.

As far as the clutch goes- sucks that a new clutch is slipping. When I was talking with exedy, I thought that the clutch would hold. I really didn't anticipate making more than 400tq- as my previous setup only yielded around 300. I also didn't anticipate making more power and torque a lot earlier than before.

Something in the engine and setup is a lot more efficient than before. When this is all said and done, it should be monster.

Retune date is the 25th. Once again, stay tuned!

Attachments

Last edited:

Maybe 44mm wastegate not big enough to controll the boost. I remember talk to Wil about use 44mm wastegate instead of the 46mm before i bought the y pipe from him, and he experienced with boost creep on 44mm thats why he using 46mm.

The 44 will flow fine and control the pressure, given it is routed correctly. If you take a look at lovefabs wastegate placement or even stmpo's y-pipe, you'll see they have a direct route outwards going with the stream of exhaust, not against it doing a 180* u turn like the one on the angus y-pipe. It's inefficient to have it that way. I would rather have a smaller gate that flows in the correct direction, than a larger one going the wrong way.

Yeah Wil wastegate is not route correct or ideal way. Been dicuss before http://www.nsxprime.com/forum/showthread.php/149718-Dyno-trouble. The turbo placement is too far to the right, leave no space to run wastegate correctly. Maybe u have to place wastegate little bit far away from the turbo with 2 pipe into one wastegate. Cant wait to see dyno run

^damn. I wish I would have seen that thread before! Wtf.

Did you get a chance to see if you had the same issue with the wastegate or had you already started to modify the location?

Did you get a chance to see if you had the same issue with the wastegate or had you already started to modify the location?

Not the same issue. My wastegate is different from the OP in that thread mentioned. I'm running a TiAL v44 and he was using a precision. I know the vacuum line for the gate is routed correctly because we tested it. The gate is definitely opening up when it should, just not flowing out enough. The pipe will be modified this week and should solve the issue with spike.

- Joined

- 7 March 2008

- Messages

- 175

Great numbers. Congrats. What injectors are you running? What's your base fuel pressure, and the duty cycle on the injectors when it made 500+?

If it was easy, everybody would be doing it!

Those are some big steps in the right direction Xavi. When all said and done, that nsx will be a force to reckon with on the streets.

How where your intake airtemps on the dyno?

Those are some big steps in the right direction Xavi. When all said and done, that nsx will be a force to reckon with on the streets.

How where your intake airtemps on the dyno?

Great numbers. Congrats. What injectors are you running? What's your base fuel pressure, and the duty cycle on the injectors when it made 500+?

Siemens 630cc injectors. Duty cycle at 15PSI was 80% <--eek

If it was easy, everybody would be doing it!

Those are some big steps in the right direction Xavi. When all said and done, that nsx will be a force to reckon with on the streets.

How where your intake airtemps on the dyno?

Compared to last years tune, the iAT temperature difference was HUGE. Last years tune (about the same ambient air temp) the highest logged air temp was 115*F. with the water/air intercooler and aluminum charge pipes- highest recorded temp was 80*F (about 30 above ambient).

Finished up the tuning today. final #'s are 539WHP and 392TQ at 10PSI of boost.

Very happy with the end result.

Special thanks goes out to:

-John Kerr and Derek Robinson at Innovative Motorworks in Carlisle PA. If any local NSX owners need tuning or fabrication solutions, pay these guys a visit.

-David Liu DC-1, Sr Chassis Design Engineer at Honda R&D Americas.

-Tommy at AutoMasters Air Machine.

-NSXprime for keeping me motivated to finish this turd.

I have a video of the dyno run, once I figure out how to post it I will.

- Joined

- 7 March 2008

- Messages

- 175

Congrats on the Numbers. The duty cycle on those injector is a lot lower than I was expecting on e85. Gives me hope.

Congrats on the Numbers. The duty cycle on those injector is a lot lower than I was expecting on e85. Gives me hope.

This is on pump gas. I haven't done the E85 conversion yet.

- Joined

- 1 July 2011

- Messages

- 219

I went to check this build thread to make sure this was you...but I definitely caught your car this weekend. So much more beautiful in person.

Wow, nice numbers! I also must say those pics posted above this post are beautiful.Finished up the tuning today. final #'s are 539WHP and 392TQ at 10PSI of boost.

I went to check this build thread to make sure this was you...but I definitely caught your car this weekend. So much more beautiful in person.

Thanks man! Nice pics- wish I would have caught you to check out your NSX. I think I saw you rolling in, but didn't see where you parked.

- Joined

- 4 January 2008

- Messages

- 177

wow amazing build! im going to look into this turbo kit myself