I'm in the process of reinstalling the transmission after swapping in short gears. Last night I tried to torque the bolt that attaches the upper A arm to the rear subframe and the threads pulled out! The rear subframe is aluminum, the bolt is M10x1.25 and the torque value is 43 ft lbs.

What is the best way to make this repair?

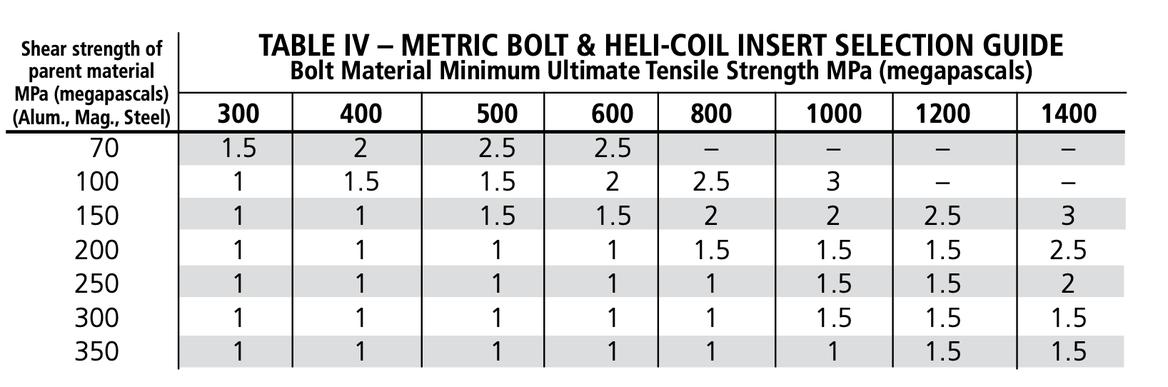

1. Helicoil

2. Timesert

3. Keensert

4. Replace the entire left rear subframe

What is the best way to make this repair?

1. Helicoil

2. Timesert

3. Keensert

4. Replace the entire left rear subframe