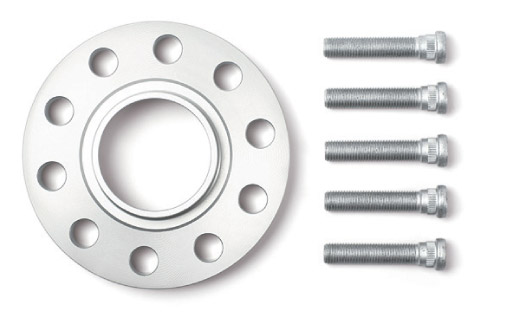

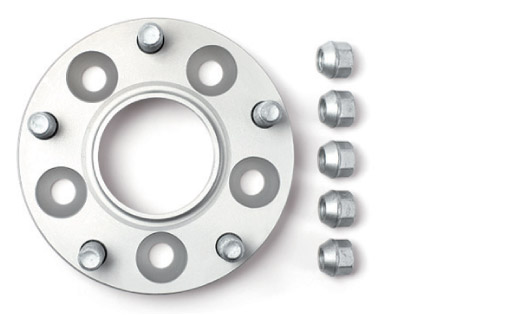

Last weekend I installed a set of the 15mm Ichiba V1 spacers. I noticed that I had more thread engagement for my lug nuts without the spacers. Prior to the spacers the lugs nuts threaded on about 9 full turns (by hand) with the new set I have 6.5 turns. That roughly works out to about 15.5 mm of thread engagement in the lug nut vs. the 19.5 mm I had without the spacers.

Does anyone know if that is within spec?

I do check my torque often on my car…

Does anyone know if that is within spec?

I do check my torque often on my car…