I've had some struggles since I got my car, like a faulty boost-a-pump connection, leaking bypass hose, my fuel pump failing, the engine lifting the heads off the block, and an overwhelmed FPR and clogged vacuum hose. But having to get the engine rebuilt provided a good opportunity to change the fueling from the stock Comptech setup of RRFPR to larger injectors and a piggyback (need to maintain OBD2 emissions testing). I've always been unhappy with the idea of the stock fueling.

So today, John Kerr of JK Tuning set up my maps for me. Let me start by saying what a great person he is. He does nothing but tune cars and develop ECU modifications for Nissans, called the NismoTronic, and he was extremely helpful and engaging during the process both before and during the tune.

I have a smaller pulley but because I am just recovering from an engine rebuild, I'm scared of running it. So I kept the standard, low-boost pulley. Based on comments here, I did pick up a water-meth spray kit from the marketplace, and have it in the trunk. I'd like to set it up with a post-blower spray but haven't had the resources and understanding that I need to so that. So I set it up to spray before the blower, to help manage temps a bit. Just water, and it seemed to cool things a lot. We were getting at least 30 degF lower IAT when spraying.

I asked John to tune for safety over performance, so he maintained 0.5 deg/psi of retard in boost.

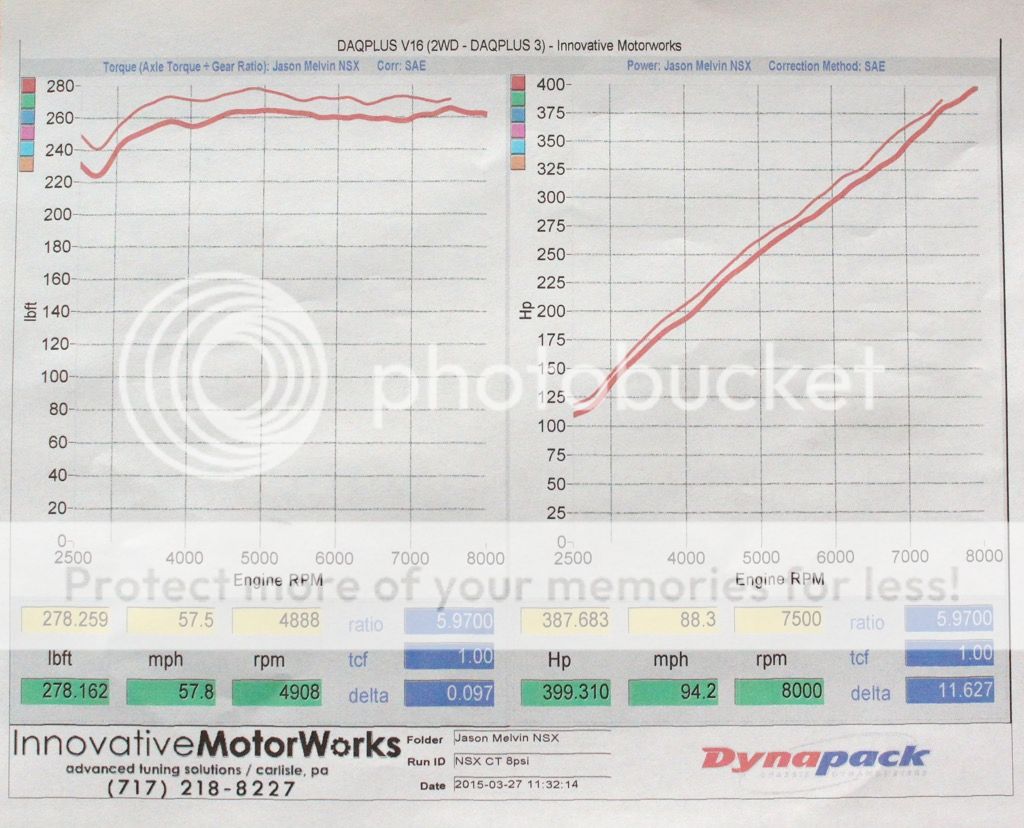

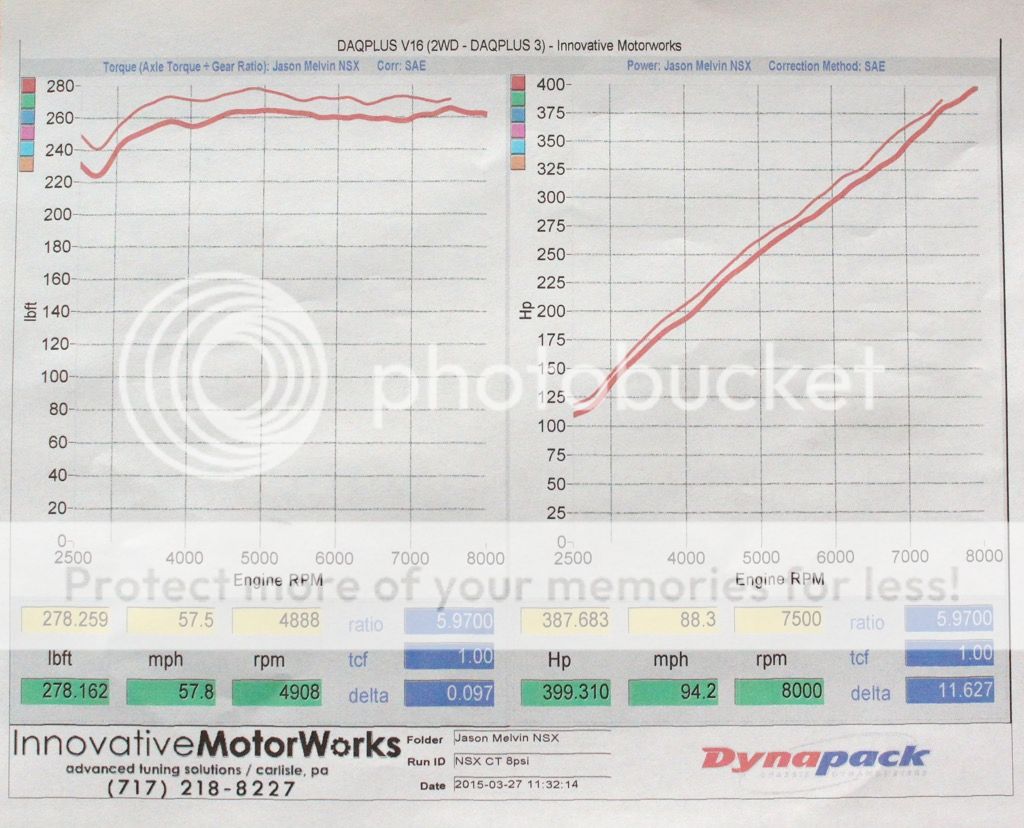

Here is the final result, 399.3 whp and 278 lb-ft:

The torque curve is nice and flat all the way to redline. And it really feels great in the car. It's now so much smoother and stronger than it has ever felt.

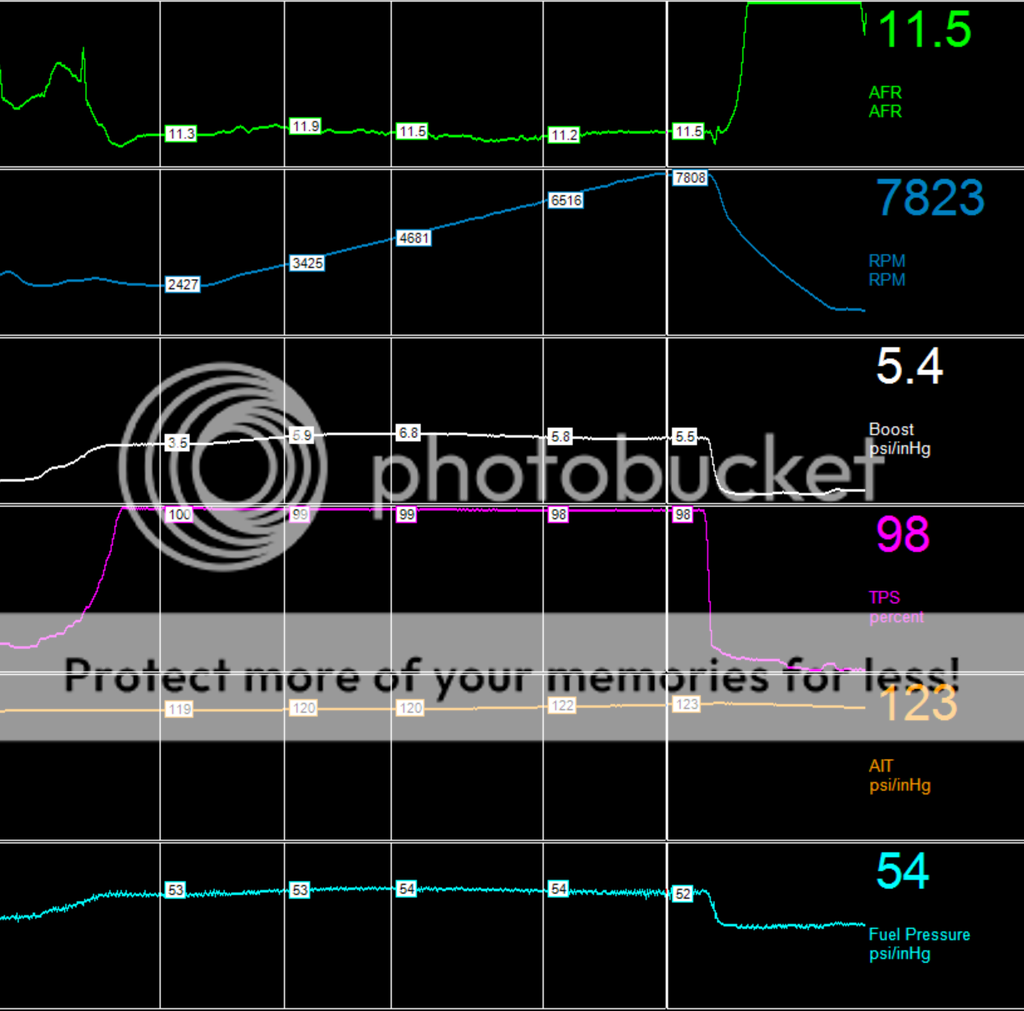

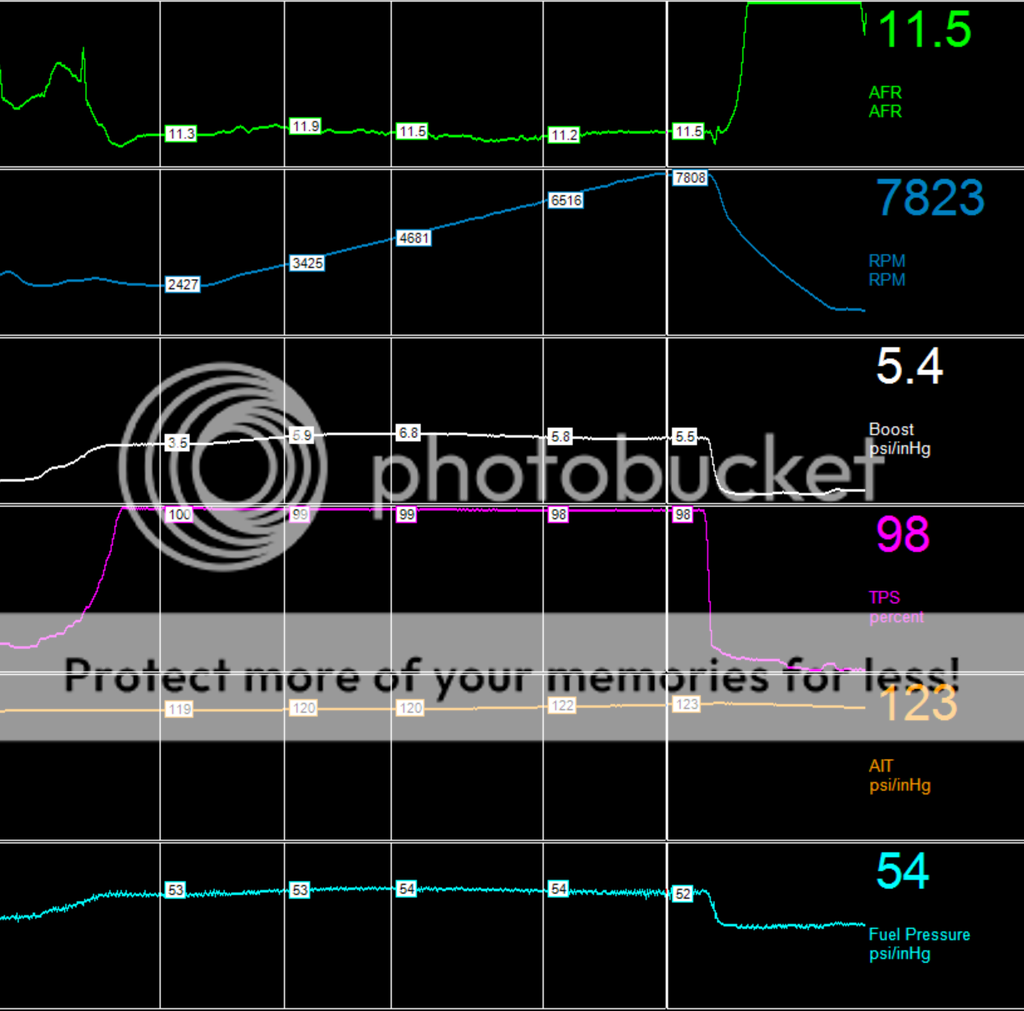

I laughed when I logged with the Zeitronix during one of the pulls and looked at the AFR. The stock Comptech setup never was this flat:

It looks like boost is falling off a bit at higher RPM, which suggests belt slip. I tightened it at one point, which seemed to help. The Dynapack reported a higher pressure than the Zeitronix. Also, it seems like the water spray may raise the boost in the mid-rpm range.

Here's a picture of the nonfinal, somewhat hurried spray setup:

In all, it was a great experience and a great day. I stopped in at Daisy to see Ben [MENTION=14909]redbird92[/MENTION] on the way home and give him a hug for building me a great engine. And to change the break-in, dyno oil to some fresh synthetic.

Thanks to Ben [MENTION=14909]redbird92[/MENTION], Dave [MENTION=4799]DDozier[/MENTION], Regan [MENTION=20915]RYU[/MENTION], and John Kerr. All played a critical role in my education, setup, and results. I still have a little work to do on the spray setup but I'm very happy. -jason

So today, John Kerr of JK Tuning set up my maps for me. Let me start by saying what a great person he is. He does nothing but tune cars and develop ECU modifications for Nissans, called the NismoTronic, and he was extremely helpful and engaging during the process both before and during the tune.

I have a smaller pulley but because I am just recovering from an engine rebuild, I'm scared of running it. So I kept the standard, low-boost pulley. Based on comments here, I did pick up a water-meth spray kit from the marketplace, and have it in the trunk. I'd like to set it up with a post-blower spray but haven't had the resources and understanding that I need to so that. So I set it up to spray before the blower, to help manage temps a bit. Just water, and it seemed to cool things a lot. We were getting at least 30 degF lower IAT when spraying.

I asked John to tune for safety over performance, so he maintained 0.5 deg/psi of retard in boost.

Here is the final result, 399.3 whp and 278 lb-ft:

The torque curve is nice and flat all the way to redline. And it really feels great in the car. It's now so much smoother and stronger than it has ever felt.

I laughed when I logged with the Zeitronix during one of the pulls and looked at the AFR. The stock Comptech setup never was this flat:

It looks like boost is falling off a bit at higher RPM, which suggests belt slip. I tightened it at one point, which seemed to help. The Dynapack reported a higher pressure than the Zeitronix. Also, it seems like the water spray may raise the boost in the mid-rpm range.

Here's a picture of the nonfinal, somewhat hurried spray setup:

In all, it was a great experience and a great day. I stopped in at Daisy to see Ben [MENTION=14909]redbird92[/MENTION] on the way home and give him a hug for building me a great engine. And to change the break-in, dyno oil to some fresh synthetic.

Thanks to Ben [MENTION=14909]redbird92[/MENTION], Dave [MENTION=4799]DDozier[/MENTION], Regan [MENTION=20915]RYU[/MENTION], and John Kerr. All played a critical role in my education, setup, and results. I still have a little work to do on the spray setup but I'm very happy. -jason