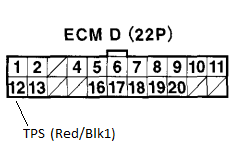

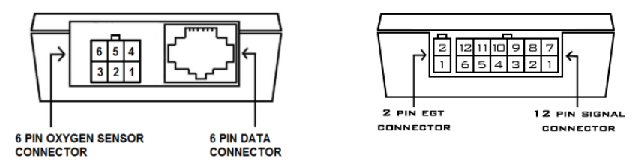

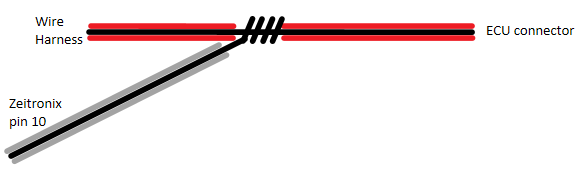

The Zeitronix has a dedicated TPS wire, which connects to the ECU harness. Same with rpm. Fuel pressure required buying a pressure sensor from Zeitronix, essentially the same as the boost sensor but measuring gauge pressure rather than absolute. That is connected to the User1 input, while the IAT is connected to User2.

Thanks for the (very) quick reply

I didn't know I could read that information too. Will have to look into how to get the TPS signal from the ECU into the Zeitronix.

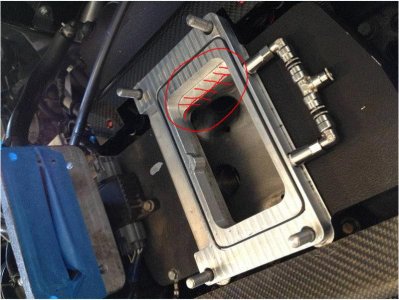

I have the fuel pressure gauge in my engine bay, but I obviously would need another sensor for the Zeitronix as well.

Do you have the Zeitronix LCD-display as well? It seems I would not be able to display all that data as I drive on one display unfortunately.