We need to do a group buy or something so they'll make more for us.Ben got literally one of the last ones from the last batch

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bogle's 1991 mild build thread

- Thread starter bogle

- Start date

The car is running well, but of course there are still some issues to work through.

On the smaller side, it had some idle and startup quirks that I managed to fix:

- It wouldn’t idle high on cold start. I ended up backing out the donut inside the FITV 3 turns from tight (fewer turns didn’t help) and now it idles high enough again.

- It idled pretty lean, I think this is because it pulls very slightly more vacuum at idle than before. That puts idle in fuel map cells that were mostly untouched before. I wonder if more vacuum is caused by the new, not-ripped diaphragm?

- Hot start was more jacked than before? Not sure, but I ended up pulling a lot of fuel out of the cranking table. Now it fires right up near operating temp

Ok. On to the bigger stuff.

Boost leak?

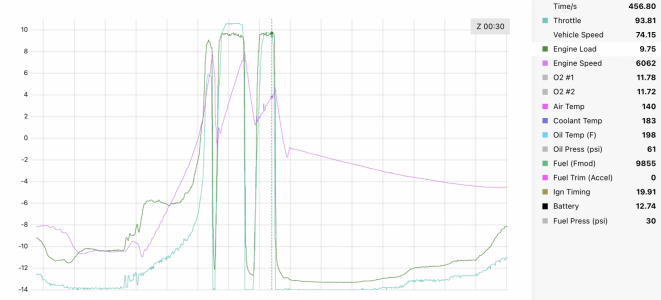

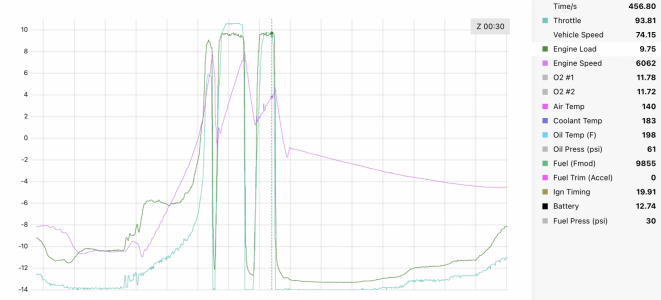

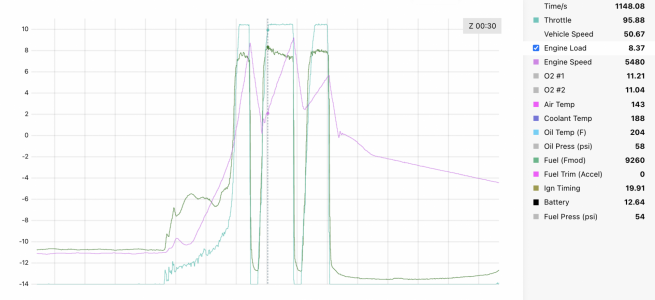

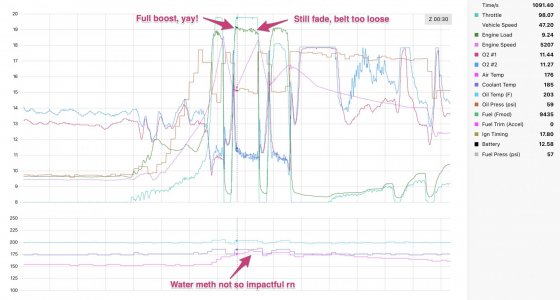

Prior to the supercharger rebuild, boost would peak about 9.5psi then bleed off only max 1/2 psi near redline. Here it is with a tight belt:

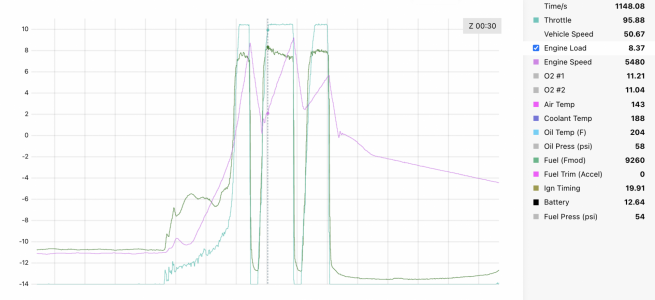

After the sc rebuild, it only shows about 8.3psi peak, derp. There is also boost fade here cause I’ve been super afraid of really tightening the belt, preferring to creep up on it. But previously, even with a no-so-tight belt, it would hit the 9.5psi peak then trail off at redline.

Not ideal. This feels like a rabbit hole. The issue could be one or more of like 15 different things, I removed everything on the manifold, so anything could be the source of the leak. Some of those things would require I pull the sc and or manifold off again :/. Hopefully it’s something easy like the injector bottom seals, and not like the bypass valve hanging open a bit, or even the phenolic plate gaskets leaking. If it’s one of the latter, I’m probably pulling the manifold again.

The plan is to replace the injectors cause that was in the cards anyway. If that’s not it, I’ll get a smoke machine that produces pressure and try to pressurize the manifold under the sc. If any of y’all have ideas on how to track a boost leak down in a supercharged setup please chime in.

Siphon

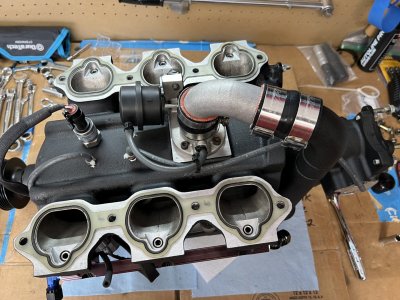

If you’ve been reading along, you’ll know that the WMI nozzle is now spraying right into the output of the supercharger. Before, it was spraying before the throttle body. That means the nozzle is now subjected to vacuum and boost.

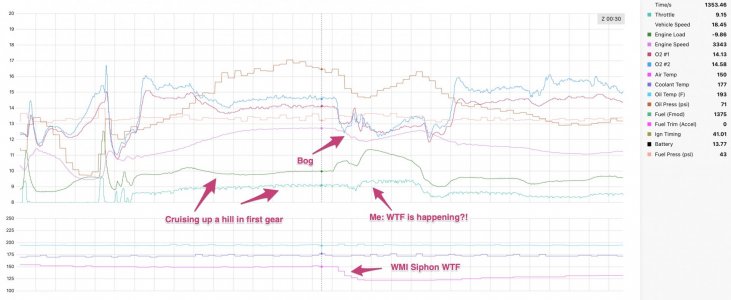

There is a solenoid in front of the nozzle, so it should be fine, right? Turns out that sometimes in vacuum, it will siphon whatever water is in the line, probably up to the solenoid. This shows up as a random drop in air temp while cruising, plus usually bogging.

The easy attempted fix was a check valve:

It’s a one way valve you put right in front of the nozzle. It doesn’t allow back flow (boost), but also doesn’t allow flow at all until it reaches a certain pressure. The pressure is called the “cracking pressure”. This one has a cracking pressure of 16psi, the highest I could find, and more than the engine produces in vacuum, right?

Installed, hard to see cause it’s covered in fire sleeve, but you get the idea. It’s like 1” from the nozzle:

Does it work? Sorta. It seems to siphon less often, but still does on occasion.

I think the real solution is to move the solenoid to be as close as possible to the new nozzle location, but that’s a project.

On the smaller side, it had some idle and startup quirks that I managed to fix:

- It wouldn’t idle high on cold start. I ended up backing out the donut inside the FITV 3 turns from tight (fewer turns didn’t help) and now it idles high enough again.

- It idled pretty lean, I think this is because it pulls very slightly more vacuum at idle than before. That puts idle in fuel map cells that were mostly untouched before. I wonder if more vacuum is caused by the new, not-ripped diaphragm?

- Hot start was more jacked than before? Not sure, but I ended up pulling a lot of fuel out of the cranking table. Now it fires right up near operating temp

Ok. On to the bigger stuff.

Boost leak?

Prior to the supercharger rebuild, boost would peak about 9.5psi then bleed off only max 1/2 psi near redline. Here it is with a tight belt:

After the sc rebuild, it only shows about 8.3psi peak, derp. There is also boost fade here cause I’ve been super afraid of really tightening the belt, preferring to creep up on it. But previously, even with a no-so-tight belt, it would hit the 9.5psi peak then trail off at redline.

Not ideal. This feels like a rabbit hole. The issue could be one or more of like 15 different things, I removed everything on the manifold, so anything could be the source of the leak. Some of those things would require I pull the sc and or manifold off again :/. Hopefully it’s something easy like the injector bottom seals, and not like the bypass valve hanging open a bit, or even the phenolic plate gaskets leaking. If it’s one of the latter, I’m probably pulling the manifold again.

The plan is to replace the injectors cause that was in the cards anyway. If that’s not it, I’ll get a smoke machine that produces pressure and try to pressurize the manifold under the sc. If any of y’all have ideas on how to track a boost leak down in a supercharged setup please chime in.

Siphon

If you’ve been reading along, you’ll know that the WMI nozzle is now spraying right into the output of the supercharger. Before, it was spraying before the throttle body. That means the nozzle is now subjected to vacuum and boost.

There is a solenoid in front of the nozzle, so it should be fine, right? Turns out that sometimes in vacuum, it will siphon whatever water is in the line, probably up to the solenoid. This shows up as a random drop in air temp while cruising, plus usually bogging.

The easy attempted fix was a check valve:

It’s a one way valve you put right in front of the nozzle. It doesn’t allow back flow (boost), but also doesn’t allow flow at all until it reaches a certain pressure. The pressure is called the “cracking pressure”. This one has a cracking pressure of 16psi, the highest I could find, and more than the engine produces in vacuum, right?

Installed, hard to see cause it’s covered in fire sleeve, but you get the idea. It’s like 1” from the nozzle:

Does it work? Sorta. It seems to siphon less often, but still does on occasion.

I think the real solution is to move the solenoid to be as close as possible to the new nozzle location, but that’s a project.

TCS delete

While the car was apart and I was waiting for parts, I took on a few random projects. One of them was deleting the TCS. My car will likely always have an aftermarket ECU so probably will never use the TCS. Turns out there is an NSX-R part that replaces the TCS computer and locates the interior mounting hole PN 83724-SL0-J50

Before:

Computer out:

It was unclear exactly how to bolt up the bracket. There are a bunch of different possible mounting holes, but these are the right ones (thanks @MotorMouth93 for the help):

There wasn’t a super clean place to mount this plug bracket. I ended up modifying the bracket a bit and mounted it to a nearby stand-off to keep it from flopping around.

That’s it! Saved 3 lbs, yay

While the car was apart and I was waiting for parts, I took on a few random projects. One of them was deleting the TCS. My car will likely always have an aftermarket ECU so probably will never use the TCS. Turns out there is an NSX-R part that replaces the TCS computer and locates the interior mounting hole PN 83724-SL0-J50

Before:

Computer out:

It was unclear exactly how to bolt up the bracket. There are a bunch of different possible mounting holes, but these are the right ones (thanks @MotorMouth93 for the help):

There wasn’t a super clean place to mount this plug bracket. I ended up modifying the bracket a bit and mounted it to a nearby stand-off to keep it from flopping around.

That’s it! Saved 3 lbs, yay

Intake air temp sensor before TB

In the previous setup, the WMI nozzle was in the rubber intake tube:

The nozzle was moved which freed up an 1/8” NPT hole in the intake tube. What to put there? I could have just plugged it, but that’s no fun.

I’ve been curious what the air intake temp is prior to the supercharger. It may be like 75F ambient out, but by the time it gets into the intake tract, the temp is probably higher. How high? Does it have a big impact on baseline air temp after the sc? A temp sensor to the rescue.

I have a rife open element temp sensor after the supercharger and it works really well, is fast acting, and has been reliable. I got another one, they sell them with a GM/Bosch IAT plug now, so that’s what I got:

Cool. In the intake tube:

And mounted in the car:

Then the harness. @MotorMouth93 told me that the wires to the TCS motor at the TB went straight to the TCS computer and I could probably reuse the pathways. I looked at the schematics and picked 2 wires (green and white/green) to run the temp sensor resistance. My harness for the engine bay with a 6 pin HW090 male that plugs into the factory female TCS plug:

At the firewall, the TCS computer uses similar plugs to the ECU: TE/Amp multilock connectors. The TCS motor wires use the “large” obd1 pins which are TE/Amp multilock 070. I had some 070 plugs floating around from another project, so used them without any cutting or re-crimping. The other side of the plug runs into a 6 channel AEM CAN expansion module:

Last bit was getting the data into the nav pod. This sensor doesn’t go into the ECU. It could, but that’d take more wiring, so navpod only for now. White is current value, grey is max from the last 30 seconds:

Getting the formula right was kind of a pain, the AEM unit gives you raw ohms for temp sensors. Temp sensors like this are super non linear, real dash only does formulas, no lookup tables, so I had to best fit a parabolic function to get close to the curve, but it’s close and is fine for now.

Data wise, temp here seems to be 10-20F over ambient all the time. It doesn’t fluctuate all that much, but will be interesting to watch over the coming months.

In the previous setup, the WMI nozzle was in the rubber intake tube:

The nozzle was moved which freed up an 1/8” NPT hole in the intake tube. What to put there? I could have just plugged it, but that’s no fun.

I’ve been curious what the air intake temp is prior to the supercharger. It may be like 75F ambient out, but by the time it gets into the intake tract, the temp is probably higher. How high? Does it have a big impact on baseline air temp after the sc? A temp sensor to the rescue.

I have a rife open element temp sensor after the supercharger and it works really well, is fast acting, and has been reliable. I got another one, they sell them with a GM/Bosch IAT plug now, so that’s what I got:

Cool. In the intake tube:

And mounted in the car:

Then the harness. @MotorMouth93 told me that the wires to the TCS motor at the TB went straight to the TCS computer and I could probably reuse the pathways. I looked at the schematics and picked 2 wires (green and white/green) to run the temp sensor resistance. My harness for the engine bay with a 6 pin HW090 male that plugs into the factory female TCS plug:

At the firewall, the TCS computer uses similar plugs to the ECU: TE/Amp multilock connectors. The TCS motor wires use the “large” obd1 pins which are TE/Amp multilock 070. I had some 070 plugs floating around from another project, so used them without any cutting or re-crimping. The other side of the plug runs into a 6 channel AEM CAN expansion module:

Last bit was getting the data into the nav pod. This sensor doesn’t go into the ECU. It could, but that’d take more wiring, so navpod only for now. White is current value, grey is max from the last 30 seconds:

Getting the formula right was kind of a pain, the AEM unit gives you raw ohms for temp sensors. Temp sensors like this are super non linear, real dash only does formulas, no lookup tables, so I had to best fit a parabolic function to get close to the curve, but it’s close and is fine for now.

Data wise, temp here seems to be 10-20F over ambient all the time. It doesn’t fluctuate all that much, but will be interesting to watch over the coming months.

G-meter sensor

I bought that pre-TB air temp sensor a while back, the shipping for the sensor alone was super expensive, no bueno. I’m all for getting suckered into the “spend X to get free shipping,” so I looked around at other sensors that might be fun to add. I had a few open inputs on the AEM can expansion module, so I had some room. Well turns out they make a G-meter that is -3 to 3 Gs:

It’s pretty simple to connect, just three 0-5v outputs. But where to mount it? It’s supposed to go as close to the center of the car as it can be and has to be pretty solidly mounted.

The old TCS area was the perfect place. I wanted it to be hidden with all the interior trim, and that area has a number of standoffs to could use for mounting. This was the spot:

Now I needed a bracket. I am not sophisticated enough to have CAD skills or a 3D printer. If I did, this would be a nice 3D printed bracket. I do have a caliper and aluminum, though, so that’s what it ended up being.

The plan was to mock it up with 1/32”, then send a drawing to my dad to make it out of 1/8”. But it ended up being sturdy enough with the two mounting points

I mounted it 90deg off what the docs said was required. The big arrow is supposed to be forward, but I didn’t have the room for the wire.

It seems fine. Mounted for real and wired up:

I updated my navpod dash to add a traction circle gauge in the bottom right. This pic was before some fiddling, so it’s not perfectly calibrated and the meter is backward F to R, but you get the idea.

It’s been fun to watch it move on the latest drives!

I bought that pre-TB air temp sensor a while back, the shipping for the sensor alone was super expensive, no bueno. I’m all for getting suckered into the “spend X to get free shipping,” so I looked around at other sensors that might be fun to add. I had a few open inputs on the AEM can expansion module, so I had some room. Well turns out they make a G-meter that is -3 to 3 Gs:

It’s pretty simple to connect, just three 0-5v outputs. But where to mount it? It’s supposed to go as close to the center of the car as it can be and has to be pretty solidly mounted.

The old TCS area was the perfect place. I wanted it to be hidden with all the interior trim, and that area has a number of standoffs to could use for mounting. This was the spot:

Now I needed a bracket. I am not sophisticated enough to have CAD skills or a 3D printer. If I did, this would be a nice 3D printed bracket. I do have a caliper and aluminum, though, so that’s what it ended up being.

The plan was to mock it up with 1/32”, then send a drawing to my dad to make it out of 1/8”. But it ended up being sturdy enough with the two mounting points

I mounted it 90deg off what the docs said was required. The big arrow is supposed to be forward, but I didn’t have the room for the wire.

It seems fine. Mounted for real and wired up:

I updated my navpod dash to add a traction circle gauge in the bottom right. This pic was before some fiddling, so it’s not perfectly calibrated and the meter is backward F to R, but you get the idea.

It’s been fun to watch it move on the latest drives!

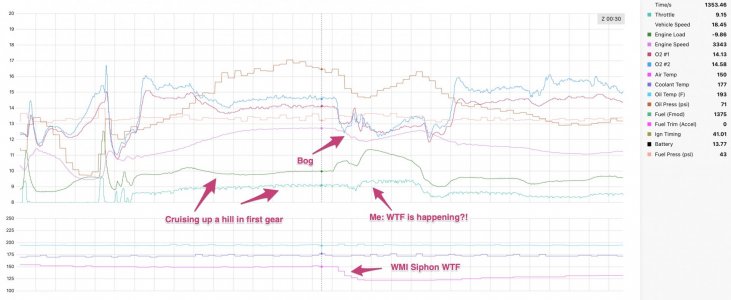

Nonsense, part 2

Well, the car had a little episode on Saturday. I was coming back from a drive, about 2 blocks from home, idling at a stop sign, when the engine started bogging along with a pretty quick drop in air temps. This is not totally uncommon, it’s caused by the manifold vacuum siphoning water out of the line. Usually this lasts a few seconds and then things go back to normal. But this time, the bogging and air temp drop didn’t stop. I should have just pulled over and shut it off, but I was so close, and it kind of does this all the time, so I drove it the 2 blocks home. Was the solenoid stuck open? Was something else causing the siphoning? In the moment I didn’t really know what was happening or what to do tbh, but getting it home seemed like the best option.

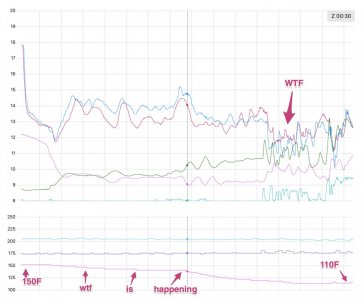

Here’s what it looked like in the data, the temp drop was a little more gradual than a normal siphon event.

I got it in the garage, hooked the laptop up, and started pulling the internal log data from the ecu. To pull the data, I have to turn the key to IGN, then it takes like a whole minute to download everything to the laptop.

While I was pulling data, there was a weird whirring noise. Hmmm, wtf?? I had the hood open, walked around the car and….. the WMI pump was _running_. Runnnning….with the engine offffff. W T F. I unplugged the pump as fast as I could then went around to the controller to unplug it too.

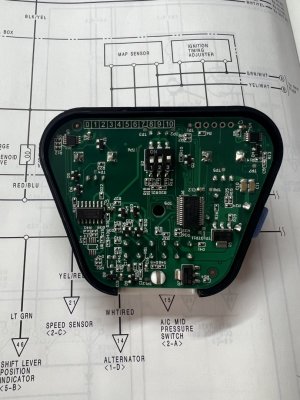

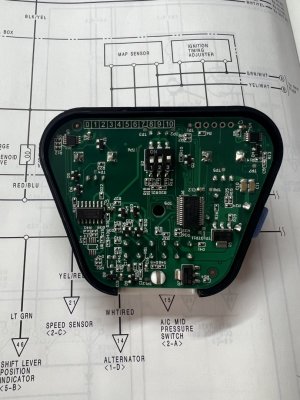

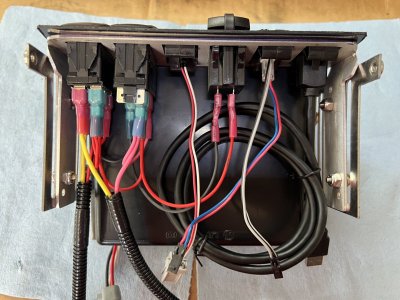

Here’s what the controller should look like mounted up:

Turns out the controller had separated from its case. I don’t have any great pics cause I was so flustered in the moment. But basically, it’s has 2 halves, here’s the POS broken apart. A keen eye will remember that when I originally opened the brand new WMI kit up, the controller was broken in exactly the same way. They ended up replacing it, but, oops it did it again:

There is a single screw holding the halves together. The mounting ears are on the back half. Here’s the back half still all mounted up

If the case separates, the front half is no longer mounted. That means the whole ass circuit board is exposed, flopping around, ready to arc on whatever it can I guess:

What I think happened was: the case separated sometime during the drive, then, still plugged in and powered up, the circuit board bounced off the mounting screw N times until some shit shorted out, causing the pump to run. Maybe it even bounced off some other grounded thing? Not sure, but the board was laying on the mounting screw when I went to unplug it.

Water

The water pump was running for probably 30 seconds with the engine off, spraying directly into the manifold. My biggest fear with this setup for sure. That means there may be pooled water in some of the cylinders. FML.

Afraid of hydrolock, I pulled all the plugs, unplugged the main relay, and turned it over. A few drops annoyingly came out of cyl 5, but thankfully not a gusher, and the other cylinders were dry.

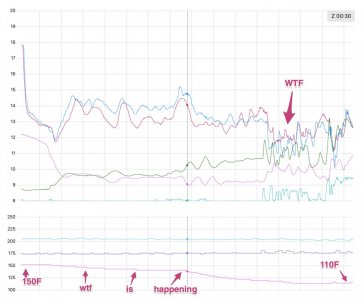

It had cooled down by this point. I started it up. It ran ok, but felt like I needed to give it throttle to keep the revs up. Also the air temps were immediately suuuper high. Everything was cool to the touch, but air temps were quickly 200F

My hypothesis is/was that the bypass valve wasn’t opening for some reason. If the bypass valve wasn’t opening, it would be starved for air and maybe whatever air in there from the outlet of the sc would be hot. Maybe there was water in some vacuum lines? Maybe in the bypass tube? Also maybe there was still water in the manifold? No idea.

Apart again

The only option to check everything was to tear it all apart again. It would also let me smoke / pressure test the manifold to find the boost leak. I probably should have done a compression test before pulling everything (is the motor jacked? I don’t know!). But I was just so paranoid that there was still lingering water in there, I didn’t want to spin it anymore.

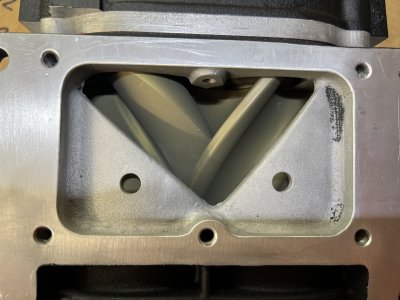

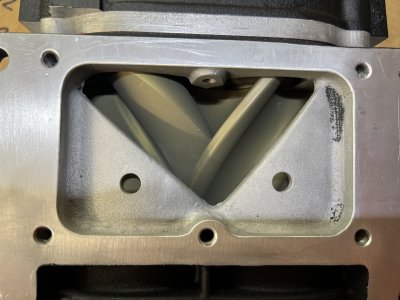

I took the blower off by itself first. If there was a pool of water in the manifold, I’d be able to sop it up.

There was, indeed, a bit of water pooled in the manifold and I did sop it up. Minor crisis averted I guess.

Then everything off again. Turns out I can pull the whole thing in under 2 hours:

The manifold had water in pretty much every orifice. The EGR ports were pretty full, some water in the bypass tube, vacuum lines too, yay.

AEM sucks

It is tough to overstate how much I dislike AEM. I guess my expectations are just too high. I was hoping for a little empathy. Maybe “Hey sorry our shitty design almost/maybe bricked your motor, happy to replace this $100 controller. We’ll let the team know this issue has happened 2/2 times.”

I’ve owned the wmi kit for a year and a half, and they have a 1 year warranty on these things. The support guy was unmoved: “The receipt you sent is 18 months old, we have a 12 month warranty. Please buy another controller.”

Anyone have recommendations for water meth controllers that use injector pulse width? I think snow makes one that takes a map signal too…

Nonsense, part 3

The end, right?

While the supercharger was upside down on the bench, I noticed a bit of blue oil leaking out of it. Hmmm not good. Well, I guess the gear case leaks a bit out the top:

But wait there’s more. The brand new rotors have scrapes on the edges. All lobes on the fat rotor look just like this. Why? I don’t know!

I emailed with Jon bond and they said something about these blowers having a weak case? But the only way to know what was up would be to send it back to them.

So back to Jon bond the supercharger goes for warranty work. To be clear, this is probably unrelated to the water episode. But I would never have known without the water episode. I wonder if there really isn’t a boost leak and the slightly lower boost is related to these scrapes or whatever poor tolerance led to them?

I am thiiiiis close to pulling the trigger on an SoS TVS supercharger kit with the intercooler. Brand new! No more WMI necessary! 12k tho. I really just want this thing running well consistently….

“Why do you think this car stuff is fun?” my girlfriend has asked like 10 times since Saturday

Well, the car had a little episode on Saturday. I was coming back from a drive, about 2 blocks from home, idling at a stop sign, when the engine started bogging along with a pretty quick drop in air temps. This is not totally uncommon, it’s caused by the manifold vacuum siphoning water out of the line. Usually this lasts a few seconds and then things go back to normal. But this time, the bogging and air temp drop didn’t stop. I should have just pulled over and shut it off, but I was so close, and it kind of does this all the time, so I drove it the 2 blocks home. Was the solenoid stuck open? Was something else causing the siphoning? In the moment I didn’t really know what was happening or what to do tbh, but getting it home seemed like the best option.

Here’s what it looked like in the data, the temp drop was a little more gradual than a normal siphon event.

I got it in the garage, hooked the laptop up, and started pulling the internal log data from the ecu. To pull the data, I have to turn the key to IGN, then it takes like a whole minute to download everything to the laptop.

While I was pulling data, there was a weird whirring noise. Hmmm, wtf?? I had the hood open, walked around the car and….. the WMI pump was _running_. Runnnning….with the engine offffff. W T F. I unplugged the pump as fast as I could then went around to the controller to unplug it too.

Here’s what the controller should look like mounted up:

Turns out the controller had separated from its case. I don’t have any great pics cause I was so flustered in the moment. But basically, it’s has 2 halves, here’s the POS broken apart. A keen eye will remember that when I originally opened the brand new WMI kit up, the controller was broken in exactly the same way. They ended up replacing it, but, oops it did it again:

There is a single screw holding the halves together. The mounting ears are on the back half. Here’s the back half still all mounted up

If the case separates, the front half is no longer mounted. That means the whole ass circuit board is exposed, flopping around, ready to arc on whatever it can I guess:

What I think happened was: the case separated sometime during the drive, then, still plugged in and powered up, the circuit board bounced off the mounting screw N times until some shit shorted out, causing the pump to run. Maybe it even bounced off some other grounded thing? Not sure, but the board was laying on the mounting screw when I went to unplug it.

Water

The water pump was running for probably 30 seconds with the engine off, spraying directly into the manifold. My biggest fear with this setup for sure. That means there may be pooled water in some of the cylinders. FML.

Afraid of hydrolock, I pulled all the plugs, unplugged the main relay, and turned it over. A few drops annoyingly came out of cyl 5, but thankfully not a gusher, and the other cylinders were dry.

It had cooled down by this point. I started it up. It ran ok, but felt like I needed to give it throttle to keep the revs up. Also the air temps were immediately suuuper high. Everything was cool to the touch, but air temps were quickly 200F

My hypothesis is/was that the bypass valve wasn’t opening for some reason. If the bypass valve wasn’t opening, it would be starved for air and maybe whatever air in there from the outlet of the sc would be hot. Maybe there was water in some vacuum lines? Maybe in the bypass tube? Also maybe there was still water in the manifold? No idea.

Apart again

The only option to check everything was to tear it all apart again. It would also let me smoke / pressure test the manifold to find the boost leak. I probably should have done a compression test before pulling everything (is the motor jacked? I don’t know!). But I was just so paranoid that there was still lingering water in there, I didn’t want to spin it anymore.

I took the blower off by itself first. If there was a pool of water in the manifold, I’d be able to sop it up.

There was, indeed, a bit of water pooled in the manifold and I did sop it up. Minor crisis averted I guess.

Then everything off again. Turns out I can pull the whole thing in under 2 hours:

The manifold had water in pretty much every orifice. The EGR ports were pretty full, some water in the bypass tube, vacuum lines too, yay.

AEM sucks

It is tough to overstate how much I dislike AEM. I guess my expectations are just too high. I was hoping for a little empathy. Maybe “Hey sorry our shitty design almost/maybe bricked your motor, happy to replace this $100 controller. We’ll let the team know this issue has happened 2/2 times.”

I’ve owned the wmi kit for a year and a half, and they have a 1 year warranty on these things. The support guy was unmoved: “The receipt you sent is 18 months old, we have a 12 month warranty. Please buy another controller.”

Anyone have recommendations for water meth controllers that use injector pulse width? I think snow makes one that takes a map signal too…

Nonsense, part 3

The end, right?

While the supercharger was upside down on the bench, I noticed a bit of blue oil leaking out of it. Hmmm not good. Well, I guess the gear case leaks a bit out the top:

But wait there’s more. The brand new rotors have scrapes on the edges. All lobes on the fat rotor look just like this. Why? I don’t know!

I emailed with Jon bond and they said something about these blowers having a weak case? But the only way to know what was up would be to send it back to them.

So back to Jon bond the supercharger goes for warranty work. To be clear, this is probably unrelated to the water episode. But I would never have known without the water episode. I wonder if there really isn’t a boost leak and the slightly lower boost is related to these scrapes or whatever poor tolerance led to them?

I am thiiiiis close to pulling the trigger on an SoS TVS supercharger kit with the intercooler. Brand new! No more WMI necessary! 12k tho. I really just want this thing running well consistently….

“Why do you think this car stuff is fun?” my girlfriend has asked like 10 times since Saturday

I know it's not fashionable these days, but you may want to look into centrifugal superchargers. They are simpler in layout and don't have the same heat soak issues as the roots-type blowers. There are old Basch units circulating out there, and you can ditch that paperweight AEM ecu and replace with a Motec or Haltech...I am thiiiiis close to pulling the trigger on an SoS TVS supercharger kit with the intercooler. Brand new! No more WMI necessary! 12k tho. I really just want this thing running well consistently….

“Why do you think this car stuff is fun?” my girlfriend has asked like 10 times since Saturday

You could also do the Dali "Boostzilla" style that keeps the blower on the belt side of the engine. If I eve SC'd a NSX, this is how I would do it- very clean. I'm sure a CNC shop could fab you the proper brackets.

Last edited:

That is neat, you could properly use the passenger scoop for the intake which feels clean.

If I change the setup, I would try to optimize for minimal fiddling. That’d be the main reason for the SoS setup, all new bits and a known good, tested solution that works together. I’d even run my current ecu for a while . A centrifugal setup would require piecing something together or buying an old, unknown condition kit, which would probably require a bunch more fiddling and problem solving.

. A centrifugal setup would require piecing something together or buying an old, unknown condition kit, which would probably require a bunch more fiddling and problem solving.

I really do want that haltech. Someday… the plan now is to have a more stable setup, then pull the trigger on that haltech.

If I was able to get this thing running with reliable air temps, full boost, and legit afrs on the new injectors by the end of the year, that feels pretty realistic. Then I could forget about the dumb motor for a minute and do some other things on the list. Maybe haltech next year?

If I change the setup, I would try to optimize for minimal fiddling. That’d be the main reason for the SoS setup, all new bits and a known good, tested solution that works together. I’d even run my current ecu for a while

I really do want that haltech. Someday… the plan now is to have a more stable setup, then pull the trigger on that haltech.

If I was able to get this thing running with reliable air temps, full boost, and legit afrs on the new injectors by the end of the year, that feels pretty realistic. Then I could forget about the dumb motor for a minute and do some other things on the list. Maybe haltech next year?

Center console rework

The supercharger is stiiiilll at the rebuilder, so I’ve been slowly improving smaller things elsewhere.

My center console is jank. I removed the headunit a while back and now run the stereo from the screen in the navpod. In the headunit’s place, I put 2 single din pockets cause I wasn’t sure what else to do:

Not pretty eh? Over time I’ve slowly added wires hanging out of the thing: the WMI led, alarm stuff, and a plug (pink and yellow wires there) to totally cut power to the navpod cause it has a heavy current draw when sitting.

On top of that I needed to add a switch for the WMI controller. The last wmi controller failed and I had no way to turn it off other than unplugging the controller. Now running WMI without a kill switch feels super risky, so adding a switch was pretty important.

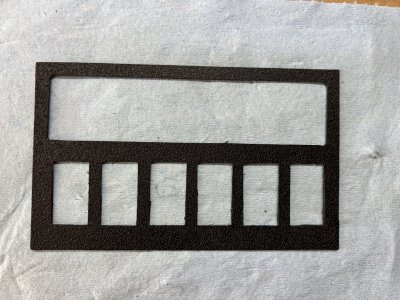

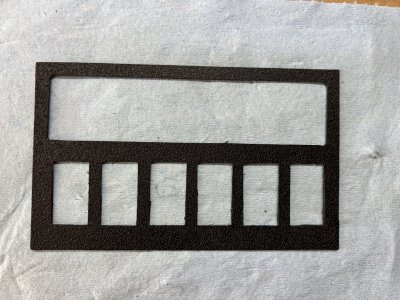

Instead of another loose thing floating around in one of the din pockets, I figured I’d try to make the whole thing nicer. Well here’s the final product:

It’s not perfect, but better eh?

The switches are Carling contura V rocker switches (20A). These rockers are super popular with the 4x4 and boat crowds. Tons of places sell laser cut rocker covers. I bought a whole bunch of covers with different icons. Left one is the nav pod power with a CB radio icon. The right one is the WMI switch with a bilge pump icon, kinda looks like a supercharger spraying water, right??

There are also a number of switch panels for these switches out there. I bought a couple “single din” panels and they didn’t fit at all:

The carling one (top) was too skinny, and the mudstuff.co.uk one was too wide. I found an aluminum one for a Tacoma from paranoid fab. It also kind of didn’t fit, but was easier to adjust and gave me some ideas on how to combine the switch panel and pocket all together.

Here it is bolted to the outside of the stereo cage. It was about 1/4” too wide, and the cage didn’t fit in the console with the panel mounted on the outside. I bent the sides to make it skinnier at the mounting cage. I wish I had a little brake, but I have clamps and flat bar.

Time consuming, but it did an ok job:

Mocked up in the console:

Then I cut a billion little rectangles out of a piece of ABS. It’s pretty rough here, but after a bunch of filing, things were more evened out.

Filed and mocked up. I got a bunch of carling blanks and used the blanks for the WMI led, alarm things, and the navpod’s USB port. The other part in there is a voltmeter, I was thinking maybe I could get rid of the last remaining gauge in the car which is an aem volts gauge.

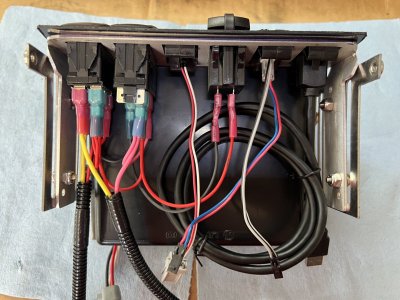

Wired! Some day maybe I’ll put it all on one plug, but currently using separate plugs for everything.

It’s a whole lot better, but not final. I’m still not 100% sure what the ultimate center console config will be. I’d like to use the coin tray factory switches instead of these, or maybe have these switches under the ashtray flap or something. Maybe have euro boutique make me a custom carbon console piece. Not sure yet

The supercharger is stiiiilll at the rebuilder, so I’ve been slowly improving smaller things elsewhere.

My center console is jank. I removed the headunit a while back and now run the stereo from the screen in the navpod. In the headunit’s place, I put 2 single din pockets cause I wasn’t sure what else to do:

Not pretty eh? Over time I’ve slowly added wires hanging out of the thing: the WMI led, alarm stuff, and a plug (pink and yellow wires there) to totally cut power to the navpod cause it has a heavy current draw when sitting.

On top of that I needed to add a switch for the WMI controller. The last wmi controller failed and I had no way to turn it off other than unplugging the controller. Now running WMI without a kill switch feels super risky, so adding a switch was pretty important.

Instead of another loose thing floating around in one of the din pockets, I figured I’d try to make the whole thing nicer. Well here’s the final product:

It’s not perfect, but better eh?

The switches are Carling contura V rocker switches (20A). These rockers are super popular with the 4x4 and boat crowds. Tons of places sell laser cut rocker covers. I bought a whole bunch of covers with different icons. Left one is the nav pod power with a CB radio icon. The right one is the WMI switch with a bilge pump icon, kinda looks like a supercharger spraying water, right??

There are also a number of switch panels for these switches out there. I bought a couple “single din” panels and they didn’t fit at all:

The carling one (top) was too skinny, and the mudstuff.co.uk one was too wide. I found an aluminum one for a Tacoma from paranoid fab. It also kind of didn’t fit, but was easier to adjust and gave me some ideas on how to combine the switch panel and pocket all together.

Here it is bolted to the outside of the stereo cage. It was about 1/4” too wide, and the cage didn’t fit in the console with the panel mounted on the outside. I bent the sides to make it skinnier at the mounting cage. I wish I had a little brake, but I have clamps and flat bar.

Time consuming, but it did an ok job:

Mocked up in the console:

Then I cut a billion little rectangles out of a piece of ABS. It’s pretty rough here, but after a bunch of filing, things were more evened out.

Filed and mocked up. I got a bunch of carling blanks and used the blanks for the WMI led, alarm things, and the navpod’s USB port. The other part in there is a voltmeter, I was thinking maybe I could get rid of the last remaining gauge in the car which is an aem volts gauge.

Wired! Some day maybe I’ll put it all on one plug, but currently using separate plugs for everything.

It’s a whole lot better, but not final. I’m still not 100% sure what the ultimate center console config will be. I’d like to use the coin tray factory switches instead of these, or maybe have these switches under the ashtray flap or something. Maybe have euro boutique make me a custom carbon console piece. Not sure yet

Fantastic work! So cool to see you create your own solutions.

Thanks @mochanges!

It’s alive! I managed to get it running today and so far everything seems all good. When I tore it apart last time, it had just had a bunch of water pumped into the manifold with the engine not running by the broken water / meth controller. It was running really weird and air temps were super high right after startup. I was worried something larger was an issue.

I didn’t think I’d get it running today, but I’m getting pretty good at pulling this thing off and putting it back together, and no weird setbacks. It only took a couple hours to get it all buttoned up (minus the strut bar).

I also got a chance to test the new switches. Everything works as expected. Somethkng I didn’t even think of is that every light is a different color, derp. The radio switch is white but kind of yellow, the WMI switch is white, and the voltmeter is blue. It’s fine I guess. Maybe I’ll get another kinda yellow switch to replace the wmi one

I ended up just buying another dumb AEM wmi controller. Everything is setup for it, and it’s Achilles heel seems to be the case separating. So a belly zip tie on the new one. Hopefully no more separation. I tested it with it running and all back to normal:

I’ll go into more detail about the sc install process later. For now here’s a pic of a t-rex

I didn’t think I’d get it running today, but I’m getting pretty good at pulling this thing off and putting it back together, and no weird setbacks. It only took a couple hours to get it all buttoned up (minus the strut bar).

I also got a chance to test the new switches. Everything works as expected. Somethkng I didn’t even think of is that every light is a different color, derp. The radio switch is white but kind of yellow, the WMI switch is white, and the voltmeter is blue. It’s fine I guess. Maybe I’ll get another kinda yellow switch to replace the wmi one

I ended up just buying another dumb AEM wmi controller. Everything is setup for it, and it’s Achilles heel seems to be the case separating. So a belly zip tie on the new one. Hopefully no more separation. I tested it with it running and all back to normal:

I’ll go into more detail about the sc install process later. For now here’s a pic of a t-rex

Congrats for getting it running! Did you go with the Link setup?

Thanks! Not yet on the link setup. It was running weird before the teardown and had that boost leak, so I wanted to eliminate variables. I even still have the RC injectors in there right now, and I moved the WMI nozzle to be in front of the TB again. I'll drive it next weekend and get some data. If nothing major is weird, the next big step is the Link + EV14s. I do want to do some other junk like get an alignment and take it to a couple events, so I might try to just enjoy it for a few weeks before disrupting it again

Rebuild back again

As mentioned in the last post, the car is running again. It’s a huge sigh of relief nothing is really broken. I’ll take it out tomorrow to test for the first time in a couple months.

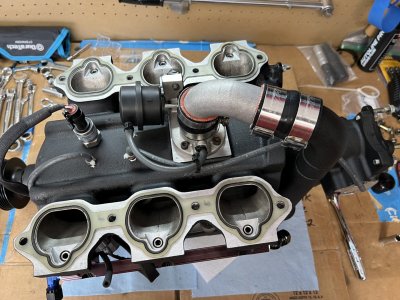

Here’s the supercharger as it came back from Jon bond performance (the rebuilder) for the second time. Check out that fat rotor on the left

If you’ve been following along, you know there were 2 issues after the last rebuild:

-One of the rotors had scrapes on it

-There was oil leaking out of the case when it was upside down

The story with the scraped rotor: they thought I had torqued the blower down incorrectly causing the rotor to scrape on the case. They said this early 1600A has a weak case, if tweaked, it can cause the same scraping I experienced. He also didn’t like the phenolic plate and attributed some of the scraping to that. I.e. The phenolic plate is softer than metal, it uses the wrong gaskets, etc.

They originally were going to repair the rotor, but ended up replacing the scraped 3-lobe (fat) rotor for other reasons, re-powdercoated the case, and only charged me for replacement of that one 3-lobe rotor (not even shipping, which was nice). I felt like I was blamed for the scraping, but they ultimately took care of me, so whatev. Newly coated rotors:

He didn’t like my x torque pattern, so we talked it out and agreed on a torque pattern, which was basically

-30 ft/lb because 3/8-24 threads

-no cross pattern. For example, left front of blower, right front, right rear, left rear, repeat.

-creep up on 30, so run through the pattern at 10, 15, 20, 25, then finally 30

-spin the blower with your hand after torqued to make sure it’s not scraping

Torque pattern for ref:

I did all that and was not scraping when spun by hand. Yay. Now it has tension on the snout from the belt, so hopefully that doesn’t contribute to the case tweak if that really is a thing.

And on. The whole unit was easier to plop down on the engine than last time. I did it on my own, rested my elbow where the garnish would be and had some leverage:

As mentioned in the last post, the car is running again. It’s a huge sigh of relief nothing is really broken. I’ll take it out tomorrow to test for the first time in a couple months.

Here’s the supercharger as it came back from Jon bond performance (the rebuilder) for the second time. Check out that fat rotor on the left

If you’ve been following along, you know there were 2 issues after the last rebuild:

-One of the rotors had scrapes on it

-There was oil leaking out of the case when it was upside down

The story with the scraped rotor: they thought I had torqued the blower down incorrectly causing the rotor to scrape on the case. They said this early 1600A has a weak case, if tweaked, it can cause the same scraping I experienced. He also didn’t like the phenolic plate and attributed some of the scraping to that. I.e. The phenolic plate is softer than metal, it uses the wrong gaskets, etc.

They originally were going to repair the rotor, but ended up replacing the scraped 3-lobe (fat) rotor for other reasons, re-powdercoated the case, and only charged me for replacement of that one 3-lobe rotor (not even shipping, which was nice). I felt like I was blamed for the scraping, but they ultimately took care of me, so whatev. Newly coated rotors:

He didn’t like my x torque pattern, so we talked it out and agreed on a torque pattern, which was basically

-30 ft/lb because 3/8-24 threads

-no cross pattern. For example, left front of blower, right front, right rear, left rear, repeat.

-creep up on 30, so run through the pattern at 10, 15, 20, 25, then finally 30

-spin the blower with your hand after torqued to make sure it’s not scraping

Torque pattern for ref:

I did all that and was not scraping when spun by hand. Yay. Now it has tension on the snout from the belt, so hopefully that doesn’t contribute to the case tweak if that really is a thing.

And on. The whole unit was easier to plop down on the engine than last time. I did it on my own, rested my elbow where the garnish would be and had some leverage:

A schmoke and a pancake

After the rebuild last time it seems like I had a boost leak. Peak psi before the rebuild was 9.5psi, and after it was about 8.3psi. Where was that extra 1psi going? During the rebuild, I took the entire manifold apart, so it could have been leaking from like 10 different places. This time, before install, I wanted to pressure test the whole setup to find any leaks.

I got a smoke machine that could also act as a compressor.

I plumbed it up to one of the vacuum lines:

And plugged everything else. They said the blower would leak some air out the inlet, so I made a quick silicone gasket for the inlet:

And I made a couple plates to block off the cylinder ports. These are 3”x1/4”x12” flat bar from Amazon. Perfect size. They are bolted down with the OE intake manifold gaskets.

I left the elbow off to test that the bypass valve was pretty sealed. It totally wasn’t sealed. You can see it smoking pretty heavily here:

Apparently the bypass valve doesn’t totally seal even in perfect conditions. But mine had some pretty obvious gaps on the edges, so I decided to replace the butterfly plate:

Jon bond makes a butterfly plate for this bypass valve. It took a bit of filing to make it fit well, now there is a lot less daylight than the old one:

After improving the bypass butterfly plate, it still let a lot of air out the bypass valve (apparently normal!). I plugged the bypass so I could check for other leaks. The EGR plate was a little problem. A new gasket and proper torque fixed that one. But there was still hissing near the EGR port. Turns out there was a pinhole leak in the manifold. Check out where it’s bubbly here:

I wonder if re-powder coating the manifold exposed this issue. Whatever. I plugged it. I chipped the powder coating in that area, exposing a little hole to the EGR port:

I cleaned it and, ahem, JB welded it. Not my finest moment, but I’m not about to have the manifold welded and re-powdercoated.

After this, no more leaks! It holds 10psi for a while and no smoke came from any orifices.

Tomorrows drive is the real test, it’s pretty close to 9psi

it’s pretty close to 9psi

After the rebuild last time it seems like I had a boost leak. Peak psi before the rebuild was 9.5psi, and after it was about 8.3psi. Where was that extra 1psi going? During the rebuild, I took the entire manifold apart, so it could have been leaking from like 10 different places. This time, before install, I wanted to pressure test the whole setup to find any leaks.

I got a smoke machine that could also act as a compressor.

I plumbed it up to one of the vacuum lines:

And plugged everything else. They said the blower would leak some air out the inlet, so I made a quick silicone gasket for the inlet:

And I made a couple plates to block off the cylinder ports. These are 3”x1/4”x12” flat bar from Amazon. Perfect size. They are bolted down with the OE intake manifold gaskets.

I left the elbow off to test that the bypass valve was pretty sealed. It totally wasn’t sealed. You can see it smoking pretty heavily here:

Apparently the bypass valve doesn’t totally seal even in perfect conditions. But mine had some pretty obvious gaps on the edges, so I decided to replace the butterfly plate:

Jon bond makes a butterfly plate for this bypass valve. It took a bit of filing to make it fit well, now there is a lot less daylight than the old one:

After improving the bypass butterfly plate, it still let a lot of air out the bypass valve (apparently normal!). I plugged the bypass so I could check for other leaks. The EGR plate was a little problem. A new gasket and proper torque fixed that one. But there was still hissing near the EGR port. Turns out there was a pinhole leak in the manifold. Check out where it’s bubbly here:

I wonder if re-powder coating the manifold exposed this issue. Whatever. I plugged it. I chipped the powder coating in that area, exposing a little hole to the EGR port:

I cleaned it and, ahem, JB welded it. Not my finest moment, but I’m not about to have the manifold welded and re-powdercoated.

After this, no more leaks! It holds 10psi for a while and no smoke came from any orifices.

Tomorrows drive is the real test,

Happy to report that the car runs well. It is back to full boost, yay. I guess maybe it's .2 or .3psi down from before the phenolic plate, but it's fine. Also the belt was pretty loose, so maybe a bit more in there.

As a test and out of paranoia, I moved the nozzle back to spray _before_ the throttle body. I thought maybe the nozzle itself, or maybe the cooling of the air post-blower could be causing the boost leak / lower pressure. I'll move the nozzle back to the phenolic plate again next week and see if things change.

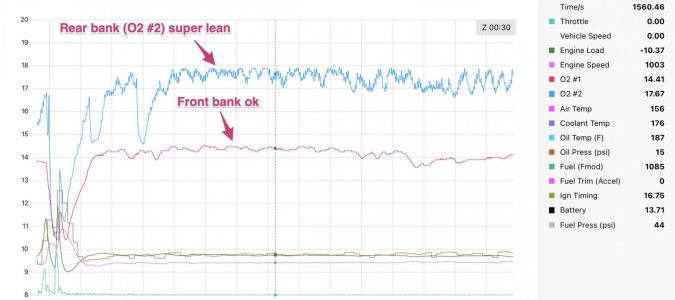

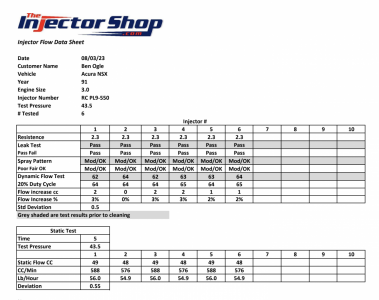

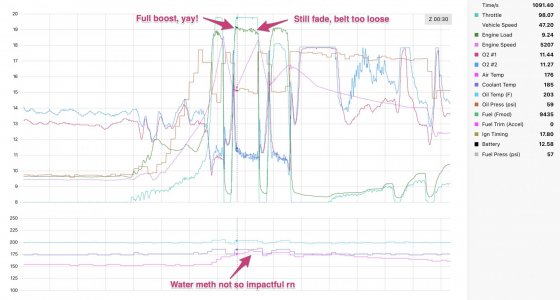

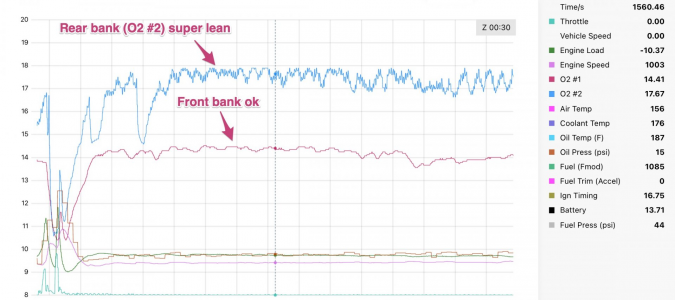

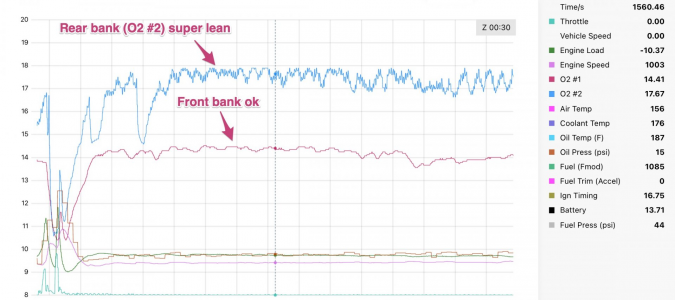

Driving the car wouldn't be the same without some weird issue I have to track down. Generally the rear bank seemed a little extra lean today under cruising loads. You can see in the chart above that the blue O2 #2 line is consistently quite a bit higher (leaner) than the red O2 #1 line, including being super lean after the pull (see big blue spike above).

After the drive, I had the car in the garage just about to shut it off, then it started occasionally burbling and the rear bank showed super lean. dafuq

Le sigh. I shut it off, waited a bit, and started it back up. After the restart, the rear bank was totally fine. So it's intermittent I guess.

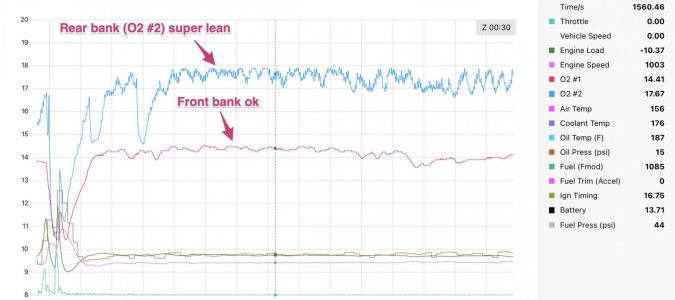

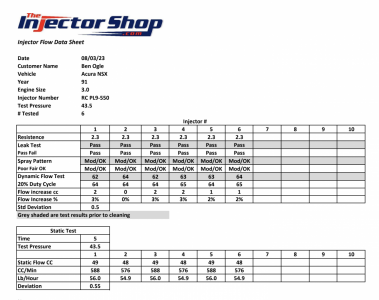

I'm still running the RC injectors here. I actually had them cleaned and flow tested out of curiosity (pic at the bottom). I put the slightly higher flow ones in the rear bank in an attempt to improve the AFR spread front to rear. But probably something else, rear coils? Wiring? Loose connector? There is a patch harness on #1 injector to trigger the WMI, maybe something loose there?

I'll replace all the rear coils and tinker with connections next week.

Here's the RC flow sheet. They were pretty clean!

As a test and out of paranoia, I moved the nozzle back to spray _before_ the throttle body. I thought maybe the nozzle itself, or maybe the cooling of the air post-blower could be causing the boost leak / lower pressure. I'll move the nozzle back to the phenolic plate again next week and see if things change.

Driving the car wouldn't be the same without some weird issue I have to track down. Generally the rear bank seemed a little extra lean today under cruising loads. You can see in the chart above that the blue O2 #2 line is consistently quite a bit higher (leaner) than the red O2 #1 line, including being super lean after the pull (see big blue spike above).

After the drive, I had the car in the garage just about to shut it off, then it started occasionally burbling and the rear bank showed super lean. dafuq

Le sigh. I shut it off, waited a bit, and started it back up. After the restart, the rear bank was totally fine. So it's intermittent I guess.

I'm still running the RC injectors here. I actually had them cleaned and flow tested out of curiosity (pic at the bottom). I put the slightly higher flow ones in the rear bank in an attempt to improve the AFR spread front to rear. But probably something else, rear coils? Wiring? Loose connector? There is a patch harness on #1 injector to trigger the WMI, maybe something loose there?

I'll replace all the rear coils and tinker with connections next week.

Here's the RC flow sheet. They were pretty clean!

Last weekend I was seeing the rear bank intermittently go lean. Here it is at idle:

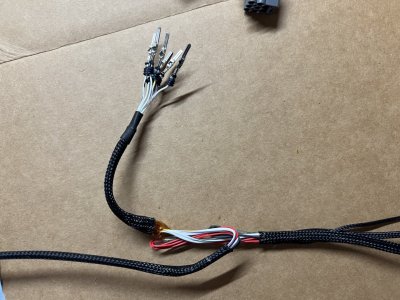

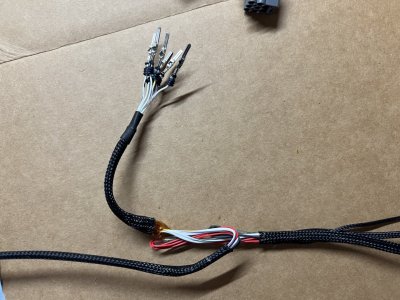

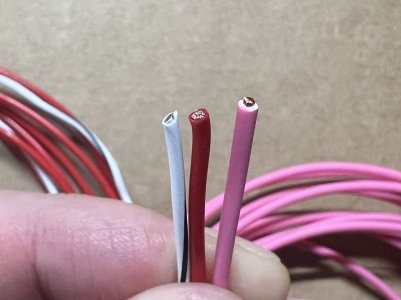

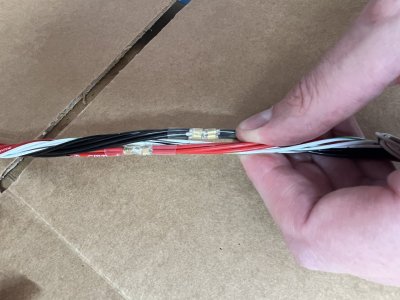

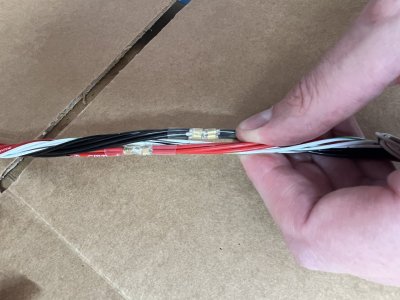

Well I managed to track down the cause today! I did a bunch of work in an effort to fix it, I replaced the rear plugs, coils, and made a better patch WMI trigger harness on the number 1 injector. Here’s the new patch harness, it uses 070 plugs, so no cutting:

I started it up, and things were fine! … For a couple minutes. Then the same rear bank leanness. Dafuq. I walked around wiggling wires: my new patch harness, the injector plugs, the harness at different points, and finally, the foundry 3 k-coil harness.

Wellllllllll when I’d mess with the coil harness I could get the leanness to come and go.

I pulled it out and did a bunch of voltmeter testing:

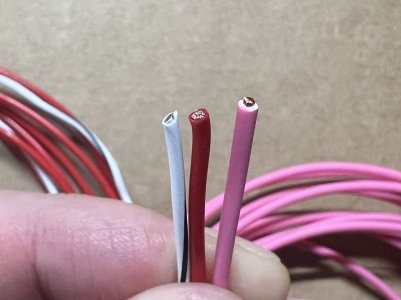

Both the number 2 and number 3 signal wires at the igniter plug would intermittently cut out when I’d move the harness around. Why??

Turns out it has shit crimps. I de-pinned the number 2 coil wire to figure out wtf. Well, I could move the wire around inside the terminal, not good. I lightly pulled and the wire came right out. Sweet. Same with cylinder 3 wire.

I guess I could fix this thing, but now I trust 0% of the crimps. Also it never has fit very well, it uses tiny wire, and the temp rating on the sheath seems low (that’s why I used the fire sleeve), so I’m just going to make my own to fix all this junk using 16 and 18 awg wire and try to make it look pretty oem.

I’m glad to have found the culprit, and it’s nice to have a reference to work off, but annoyed this harness is such low quality.

Well I managed to track down the cause today! I did a bunch of work in an effort to fix it, I replaced the rear plugs, coils, and made a better patch WMI trigger harness on the number 1 injector. Here’s the new patch harness, it uses 070 plugs, so no cutting:

I started it up, and things were fine! … For a couple minutes. Then the same rear bank leanness. Dafuq. I walked around wiggling wires: my new patch harness, the injector plugs, the harness at different points, and finally, the foundry 3 k-coil harness.

Wellllllllll when I’d mess with the coil harness I could get the leanness to come and go.

I pulled it out and did a bunch of voltmeter testing:

Both the number 2 and number 3 signal wires at the igniter plug would intermittently cut out when I’d move the harness around. Why??

Turns out it has shit crimps. I de-pinned the number 2 coil wire to figure out wtf. Well, I could move the wire around inside the terminal, not good. I lightly pulled and the wire came right out. Sweet. Same with cylinder 3 wire.

I guess I could fix this thing, but now I trust 0% of the crimps. Also it never has fit very well, it uses tiny wire, and the temp rating on the sheath seems low (that’s why I used the fire sleeve), so I’m just going to make my own to fix all this junk using 16 and 18 awg wire and try to make it look pretty oem.

I’m glad to have found the culprit, and it’s nice to have a reference to work off, but annoyed this harness is such low quality.

Welp, that convinced me to make my own harness when I do the K-coils. Glad you found the cause, but mad it was a bad part quality issue.

Definitely make your own! I think mine is not the only foundry3 harness with this issue. I’ll post details of mine as I build it to maybe demystify.

Short ratio rack

In between motor nonsense, I have been doing other stuff. One of those projects is finally installing the Quaife short ratio rack.

As you all probably already know, the stock manual steering rack has a pretty slow ratio. That means a whole lot more hand-over-hand than in other sports cars. It has a 18.2:1 ratio for 180 degrees each way from center, then it gets even slower as you move toward full lock. 18:1 is the same ratio as my 88 civic sedan. Both the current NPC daily drivers we own have a faster ratio. The nsx rack is slow and has annoyed me since I bought the car, such an iconic car with the same rack as my $800 civic! Derp.

I worked with Quaife to have a short ratio rack kit made (see the whole thread here). Here’s it is:

I had a quaife kit in my civic autox car and it was transformative, the NSX definitely deserved the same.

Getting the rack made was a process. It took over 2 years talking with Quaife, finding someone with a used rack to trust me and send it to a random address in the UK (thanks @jvtec95!), then finding someone to handle the preorder + distribution (thanks nsx rack repair!), but it got made!

The quick rack has a 15:1 ratio, which puts it in the ballpark of other cars of the era: E46 M3, AP2 S2000, Miatas, etc. It’s 20% quicker than stock, but also 20% more effort. Because it’s manual, the quicker it is, the more effort it takes to turn. After a bunch of math and talking to people, 15:1 seemed like the best tradeoff of quickness to effort increase.

It’s a “kit”, so it’s a new rack bar and pinion, nothing else. It has a 7 tooth pinion vs the stock 5 tooth, and it has a rack bar with deeper teeth to deal with the larger pinion. The pinions:

And the rack bars side by side:

Install

My OG stock rack had the common passenger side knock. My options were either a rebuild or a new rack. I opted for a brand new rack so I wouldn’t have any down time:

I’ll go into more detail installing the kit into the rack in another post if people are interested. Here it is installed, tensioned, and gooed up with moly grease.

Then old rack in the car:

Both of them side by side:

And new one installed.

I left the tie rod ends on the car and just unscrewed the inner tie rod. I marked everything’s position so there would be minimal adjustment. I managed to get the alignment straight and wheel centered right out of the gate. It only took one adjustment pass to set the toe after install:

Well is it good?!

YES. This is the rack the NSX should have from the factory. I took it on my favorite road today and the steering felt amazing, super precise, noticeably shorter. There are a couple corners where my arms used to be almost fully locked out, not anymore!

What about the effort increase? It’s not that noticeable! It is a brand new rack and I also have a knock bushing in there for hopefully extra longevity. It feels a little “stickier” and generally more solid than before. But effort increase is minimal. I have to do a several point turn to get out of the driveway and it was no problem. After 10 minutes with it I realized the ratio could have been even quicker. But it feels good and it’s probably the right balance.

I’m so glad it’s finally installed and it works well with no weird issues. Feels good that the car finally has a legit steering ratio! I agonized over the 20%. What does 20% feel like? Will it be too much? Yay that it’s not too much (for me), now I know what a 20% increase feels like.

Short ratio rack

In between motor nonsense, I have been doing other stuff. One of those projects is finally installing the Quaife short ratio rack.

As you all probably already know, the stock manual steering rack has a pretty slow ratio. That means a whole lot more hand-over-hand than in other sports cars. It has a 18.2:1 ratio for 180 degrees each way from center, then it gets even slower as you move toward full lock. 18:1 is the same ratio as my 88 civic sedan. Both the current NPC daily drivers we own have a faster ratio. The nsx rack is slow and has annoyed me since I bought the car, such an iconic car with the same rack as my $800 civic! Derp.

I worked with Quaife to have a short ratio rack kit made (see the whole thread here). Here’s it is:

I had a quaife kit in my civic autox car and it was transformative, the NSX definitely deserved the same.

Getting the rack made was a process. It took over 2 years talking with Quaife, finding someone with a used rack to trust me and send it to a random address in the UK (thanks @jvtec95!), then finding someone to handle the preorder + distribution (thanks nsx rack repair!), but it got made!

The quick rack has a 15:1 ratio, which puts it in the ballpark of other cars of the era: E46 M3, AP2 S2000, Miatas, etc. It’s 20% quicker than stock, but also 20% more effort. Because it’s manual, the quicker it is, the more effort it takes to turn. After a bunch of math and talking to people, 15:1 seemed like the best tradeoff of quickness to effort increase.

It’s a “kit”, so it’s a new rack bar and pinion, nothing else. It has a 7 tooth pinion vs the stock 5 tooth, and it has a rack bar with deeper teeth to deal with the larger pinion. The pinions:

And the rack bars side by side:

Install

My OG stock rack had the common passenger side knock. My options were either a rebuild or a new rack. I opted for a brand new rack so I wouldn’t have any down time:

I’ll go into more detail installing the kit into the rack in another post if people are interested. Here it is installed, tensioned, and gooed up with moly grease.

Then old rack in the car:

Both of them side by side:

And new one installed.

I left the tie rod ends on the car and just unscrewed the inner tie rod. I marked everything’s position so there would be minimal adjustment. I managed to get the alignment straight and wheel centered right out of the gate. It only took one adjustment pass to set the toe after install:

Well is it good?!

YES. This is the rack the NSX should have from the factory. I took it on my favorite road today and the steering felt amazing, super precise, noticeably shorter. There are a couple corners where my arms used to be almost fully locked out, not anymore!

What about the effort increase? It’s not that noticeable! It is a brand new rack and I also have a knock bushing in there for hopefully extra longevity. It feels a little “stickier” and generally more solid than before. But effort increase is minimal. I have to do a several point turn to get out of the driveway and it was no problem. After 10 minutes with it I realized the ratio could have been even quicker. But it feels good and it’s probably the right balance.

I’m so glad it’s finally installed and it works well with no weird issues. Feels good that the car finally has a legit steering ratio! I agonized over the 20%. What does 20% feel like? Will it be too much? Yay that it’s not too much (for me), now I know what a 20% increase feels like.

Welll I made a new coil harness

I even added sweet shrink tube numbers

It works! The car runs well now. I haven’t driven it cause I ran out of time Sunday, but it warmed up just fine and survived the wire wiggle test. It also fits better than the old one, has thicccer wire, and uses super high temp sleeve (insultherm 1200F).

I did fix the crimps on the foundry 3 harness too. If anyone wants a cheap k coil harness, it is for sale. Now that I know how it’s built, I can re orient it so it fits better (for a supercharged setup, anyway). That is, I will kapton tape and shrink tube this up in any orientation you want:

I’ll overshare on all the harness details in the next post. For now, here’s a schematic

I even added sweet shrink tube numbers

It works! The car runs well now. I haven’t driven it cause I ran out of time Sunday, but it warmed up just fine and survived the wire wiggle test. It also fits better than the old one, has thicccer wire, and uses super high temp sleeve (insultherm 1200F).

I did fix the crimps on the foundry 3 harness too. If anyone wants a cheap k coil harness, it is for sale. Now that I know how it’s built, I can re orient it so it fits better (for a supercharged setup, anyway). That is, I will kapton tape and shrink tube this up in any orientation you want:

I’ll overshare on all the harness details in the next post. For now, here’s a schematic

I am such a nerd for this. Nice work! I LOVE the shrink tube numbers!

I am close to doing this mod, but have decided to wait for John to figure out the OEM dwell code. Apparently it does funny things at higher RPMs. I was going to approach it by installing new connectors on the OEM wires and just running the ground wire. Using as much of the OEM loom as possible.

I am close to doing this mod, but have decided to wait for John to figure out the OEM dwell code. Apparently it does funny things at higher RPMs. I was going to approach it by installing new connectors on the OEM wires and just running the ground wire. Using as much of the OEM loom as possible.

Thanks! I def wanted it to be nice.

Yeah using the oem loom would be ideal. It’s kinda dumb the oem plugs just hang around kinda squished between things with this setup.

You could probably make a patch harness in place of the oem igniter, then some other mods to the loom. My oem coil plugs are 2 wire, so it’d require running another wire to each coil. Also the orientation of the rear k coils is weird (the connector pins are on the right of the car) and would require an extension on the stock harness to make the wires long enough to reach the coil plugs. Maybe the oem ones are just 1/4” blade connectors so you could make little patch harnesses? Not sure, but likely doable

Yeah using the oem loom would be ideal. It’s kinda dumb the oem plugs just hang around kinda squished between things with this setup.

You could probably make a patch harness in place of the oem igniter, then some other mods to the loom. My oem coil plugs are 2 wire, so it’d require running another wire to each coil. Also the orientation of the rear k coils is weird (the connector pins are on the right of the car) and would require an extension on the stock harness to make the wires long enough to reach the coil plugs. Maybe the oem ones are just 1/4” blade connectors so you could make little patch harnesses? Not sure, but likely doable

Coil harness

Here are some coil harness details. Again the finished harness:

I went down a bit of a rabbit hole with this thing. It is the biggest harness I've made, so I figured I would use it as a way to understand proper wiring bits and techniques. There is a lot to wiing, more than expected, especially if you want to build "motorsports grade" harnesses. I'd say the harness I made is probably 60% of the way to full motorsports harness. If I wanted to go all in -- use all the fancy connectors, properly concentric twist, have strong opinions on my shrink tube -- I'd probably need to rewire the whole engine.

Even this little thing was time consuming and expensive. I'm in it at least 10 hours and $250. I overbought as usual, but if I were efficient, it's still $160 in parts.

Schematic

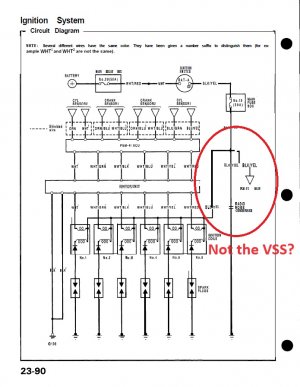

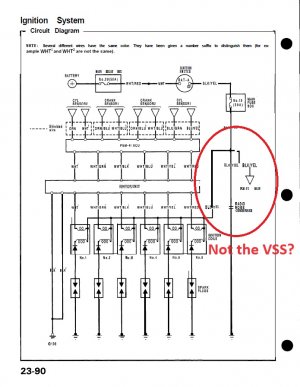

You probably saw the the schematic in the last post. Here it is again:

It's pretty simple: each coil has 3 wires, 12v power, ground, and signal.

12v power and ground comes from a VSS patch harness. The VSS 12v and ground wires are directly connected to all six coils.

The signal pin on each coil is connected to one pin on the engine harness' igniter plug.

Wire

The first rule of fancy harnesses is tefzel ("mil-spec") wire, so thats what I used. I have mostly used TXL/GXL wire in the past, but tefzel is what the cool kids use. This prowireusa page is a pretty good explainer on tefzel. The tl;dr is that there are really two kinds of tefzel wire: M22759/32 and M22759/16. /32 has less insulation than /16, otherwise they are the same. /32 is more desirable (and expensive) cause it is lighter and takes up less space.

Another thing I learned is that most "mil-spec" harnesses use really small wire, 22 awg is the norm. My foundry 3 coil harness uses 22 awg /32 tefzel, and maybe it's sufficient. I ended up going with bigger 16 and 18 awg wire, though, for a couple reasons:

1. The factory Honda (sumitomo) connectors in this harness are made for 14-18 awg wire. Likely the reason the crimps were so crappy on the foundry 3 harness is that the terminals are pretty big and the wire is tiny. Hot dog down a hallway, not ideal.

2. I want the harness to have high current carrying capacity. Good power to the coils is more important than saving 5 grams in wire weight.

I ended up with a mix of /16 and /32 wire because they were out of stock of /32 in some colors. Here's a comparison of 18 awg wires: /32, /16, and TXL:

Sleeve

Sweet, I have wire, now how to cover it?

Cool-kid mil-spec harnesses don't really use sleeving, they just use shrink tube, specifically Raychem DR-25.

The Foundry 3 harness did use sleeving, techflex flexo (I think), which is rated to 125C.

I got a bunch of different sleeving from Prowire, and liked the techflex Insultherm the best. It's super high temp (1200F), flexible, expandable, doesn't fray, and I don't have to cut if off (like shrink tube) if I need to fix something in the harness.

BOM

Here are all the bits I ended up using in the harness:

Cycleterminal:

* 6x HX 090 3 pin female connectors for each coil ($6 each)

* 1x HW 090 6 pin male connector for coil signal ($4 each)

* 1x HW 090 3 pin male connector VSS patch ($3.50 each)

* 1x HW 090 3 pin female connector VSS patch ($3.50 each)

* 4x splices 3x16 awg ($1)

* 2x splices 4x18 awg ($1)

Prowire USA:

* 13 ft red 18 awg ($1.25 / ft)

* 13 ft black 18 awg ($1.40 / ft)

* 2 ft red 16 awg ($1.50 / ft)

* 3 ft black 16 awg ($1.50 / ft)

* 18 ft 18 awg for coil signal (3 ft in 6 different colors) $1/ft

* 3 ft insultherm 1/4" (size 2) ($0.85 / ft)

* 1 ft insultherm 5/32" (size 6) ($0.50 / ft)

* 5 ft insultherm 1/8" (size 9) ($0.50 / ft)

* 1x shrinky tee booty thing ($14)

* 1x numbered shrink 6 cyl ($2)

* 1 ft non-adhesive clear shrink ($10)

* Adhesive-lined shrink tube (I bought a Raychem 4:1 kit with 5 different sizes) ($40)

* 1/2" Kapton tape ($11)

All this stuff is not cheap. I'm in this thing about $160 just in parts, I overbought. I now understand why a "mil-spec" Rywire engine harness is like $500 - $1k.

Building

I started by doing a bunch of measuring of the distance between the left side coils (cyl 3 & 6). My harness passes under the intake manifold. All power wires for all coils are spliced together, so 3 long wires between the coils for power, then the same for ground. The power wires:

I mocked them up in the engine bay 10 times to make sure it'd all fit:

I spliced all the grounds together, and all the power wires together along with wires down to the VSS

Skipping a lot of steps, here are all wires mocked up and twisted:

These are just twisted, not a proper concentric twist. A real concentric twist only really works with specific number of wires and takes a lot more planning. So either I'd have to add some filler wires in there, or a slightly gruntier twist. I opted for the latter.

Next up was taping up parts of the harness to keep the wires together before adding the sleeve. Fancy harnesses don't use black electrical tape, they use Kapton tape:

I taped every junction and split just to keep everything in the right spot. I put the most tape on the coil signal wires. I also got this cool shrink tube tee thing.

After the junction points were taped up, I sleeved everything. It was a bit tricky getting the order of operations right when installing the sleeve. The general rule was, largest sleeve went on first, so I worked from the center out.

Here's the shrink boot tee around the Insultherm:

Then after all the sleeve was on, I added the terminals and the connectors.

The end

And it works, yay. I took the car out for a super long drive this weekend and it performed perfectly. The car still has some small quirks, of course, but I don't think they are ignition harness related anymore.

Here are some coil harness details. Again the finished harness:

I went down a bit of a rabbit hole with this thing. It is the biggest harness I've made, so I figured I would use it as a way to understand proper wiring bits and techniques. There is a lot to wiing, more than expected, especially if you want to build "motorsports grade" harnesses. I'd say the harness I made is probably 60% of the way to full motorsports harness. If I wanted to go all in -- use all the fancy connectors, properly concentric twist, have strong opinions on my shrink tube -- I'd probably need to rewire the whole engine.

Even this little thing was time consuming and expensive. I'm in it at least 10 hours and $250. I overbought as usual, but if I were efficient, it's still $160 in parts.

Schematic

You probably saw the the schematic in the last post. Here it is again:

It's pretty simple: each coil has 3 wires, 12v power, ground, and signal.

12v power and ground comes from a VSS patch harness. The VSS 12v and ground wires are directly connected to all six coils.

The signal pin on each coil is connected to one pin on the engine harness' igniter plug.

Wire

The first rule of fancy harnesses is tefzel ("mil-spec") wire, so thats what I used. I have mostly used TXL/GXL wire in the past, but tefzel is what the cool kids use. This prowireusa page is a pretty good explainer on tefzel. The tl;dr is that there are really two kinds of tefzel wire: M22759/32 and M22759/16. /32 has less insulation than /16, otherwise they are the same. /32 is more desirable (and expensive) cause it is lighter and takes up less space.

Another thing I learned is that most "mil-spec" harnesses use really small wire, 22 awg is the norm. My foundry 3 coil harness uses 22 awg /32 tefzel, and maybe it's sufficient. I ended up going with bigger 16 and 18 awg wire, though, for a couple reasons:

1. The factory Honda (sumitomo) connectors in this harness are made for 14-18 awg wire. Likely the reason the crimps were so crappy on the foundry 3 harness is that the terminals are pretty big and the wire is tiny. Hot dog down a hallway, not ideal.

2. I want the harness to have high current carrying capacity. Good power to the coils is more important than saving 5 grams in wire weight.

I ended up with a mix of /16 and /32 wire because they were out of stock of /32 in some colors. Here's a comparison of 18 awg wires: /32, /16, and TXL:

Sleeve

Sweet, I have wire, now how to cover it?

Cool-kid mil-spec harnesses don't really use sleeving, they just use shrink tube, specifically Raychem DR-25.

The Foundry 3 harness did use sleeving, techflex flexo (I think), which is rated to 125C.

I got a bunch of different sleeving from Prowire, and liked the techflex Insultherm the best. It's super high temp (1200F), flexible, expandable, doesn't fray, and I don't have to cut if off (like shrink tube) if I need to fix something in the harness.

BOM

Here are all the bits I ended up using in the harness:

Cycleterminal:

* 6x HX 090 3 pin female connectors for each coil ($6 each)

* 1x HW 090 6 pin male connector for coil signal ($4 each)

* 1x HW 090 3 pin male connector VSS patch ($3.50 each)

* 1x HW 090 3 pin female connector VSS patch ($3.50 each)

* 4x splices 3x16 awg ($1)

* 2x splices 4x18 awg ($1)

Prowire USA:

* 13 ft red 18 awg ($1.25 / ft)

* 13 ft black 18 awg ($1.40 / ft)

* 2 ft red 16 awg ($1.50 / ft)

* 3 ft black 16 awg ($1.50 / ft)

* 18 ft 18 awg for coil signal (3 ft in 6 different colors) $1/ft

* 3 ft insultherm 1/4" (size 2) ($0.85 / ft)

* 1 ft insultherm 5/32" (size 6) ($0.50 / ft)

* 5 ft insultherm 1/8" (size 9) ($0.50 / ft)

* 1x shrinky tee booty thing ($14)

* 1x numbered shrink 6 cyl ($2)

* 1 ft non-adhesive clear shrink ($10)

* Adhesive-lined shrink tube (I bought a Raychem 4:1 kit with 5 different sizes) ($40)

* 1/2" Kapton tape ($11)

All this stuff is not cheap. I'm in this thing about $160 just in parts, I overbought. I now understand why a "mil-spec" Rywire engine harness is like $500 - $1k.

Building

I started by doing a bunch of measuring of the distance between the left side coils (cyl 3 & 6). My harness passes under the intake manifold. All power wires for all coils are spliced together, so 3 long wires between the coils for power, then the same for ground. The power wires:

I mocked them up in the engine bay 10 times to make sure it'd all fit:

I spliced all the grounds together, and all the power wires together along with wires down to the VSS

Skipping a lot of steps, here are all wires mocked up and twisted:

These are just twisted, not a proper concentric twist. A real concentric twist only really works with specific number of wires and takes a lot more planning. So either I'd have to add some filler wires in there, or a slightly gruntier twist. I opted for the latter.

Next up was taping up parts of the harness to keep the wires together before adding the sleeve. Fancy harnesses don't use black electrical tape, they use Kapton tape:

I taped every junction and split just to keep everything in the right spot. I put the most tape on the coil signal wires. I also got this cool shrink tube tee thing.

After the junction points were taped up, I sleeved everything. It was a bit tricky getting the order of operations right when installing the sleeve. The general rule was, largest sleeve went on first, so I worked from the center out.

Here's the shrink boot tee around the Insultherm:

Then after all the sleeve was on, I added the terminals and the connectors.

The end

And it works, yay. I took the car out for a super long drive this weekend and it performed perfectly. The car still has some small quirks, of course, but I don't think they are ignition harness related anymore.

Love the work. You've provided a blueprint for mine!

Question though: on the factory ignitor, the "feed" side is a 6-pin plug, which presumably carries the signal from the ECU for each coil. The other side of the ignitor is a 8-pin plug that sure looks like it has 2 grounds added to it. From the circuit diagram, it appears that those two grounds are for the ignitor unit itself, so a patch harness only needs 6 pins since we're deleting the ignitor. But, where does the 12V come from? On the diagram, it says the coil power comes in via a blk/yel wire from the "PGM-FI Main" via Fuse 13 (30A). Why did you use the VSS for power instead of this source?

Question though: on the factory ignitor, the "feed" side is a 6-pin plug, which presumably carries the signal from the ECU for each coil. The other side of the ignitor is a 8-pin plug that sure looks like it has 2 grounds added to it. From the circuit diagram, it appears that those two grounds are for the ignitor unit itself, so a patch harness only needs 6 pins since we're deleting the ignitor. But, where does the 12V come from? On the diagram, it says the coil power comes in via a blk/yel wire from the "PGM-FI Main" via Fuse 13 (30A). Why did you use the VSS for power instead of this source?

Similar threads

- Locked

- Replies

- 4

- Views

- 400