Update

One more day of unpaid holidays to work on the "Kalibrator":

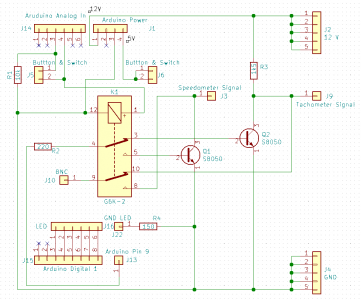

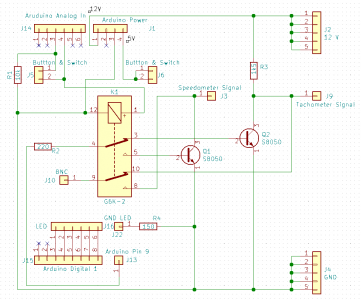

Circuit update - a pull-down resistor for the push-button was missing and a little clean-up:

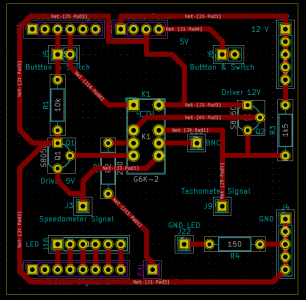

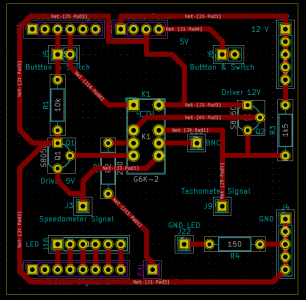

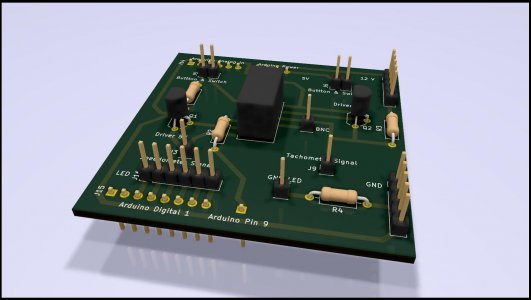

Corresponding PCB update - luckily no big change:

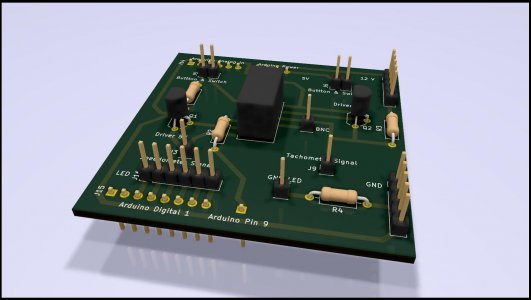

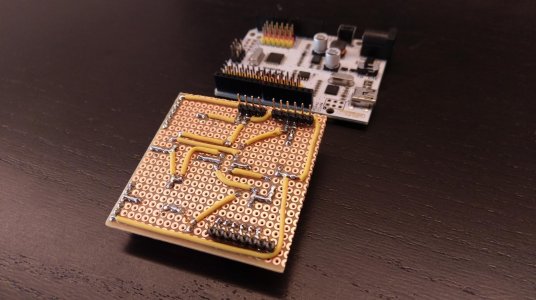

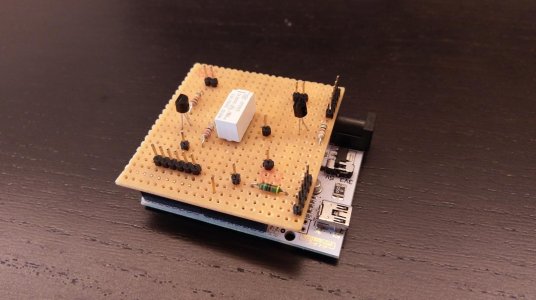

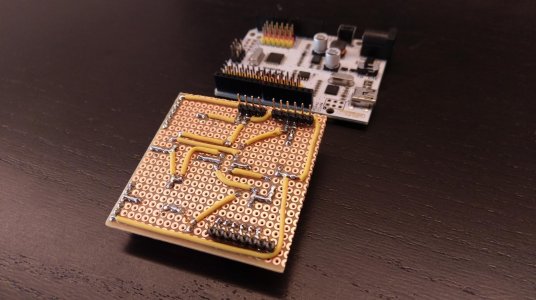

Looking at the first prototype PCB decided to make a new one, incorporating all the changes:

Then a few hours of programming to add button debouncing, Button, LED and signal generator control, start up check, cleaning up the code, etc.

All finished with a first test run connected to the gauge cluster:

As it's just have the fun with anything moving, here's a short clip with the uncalibrated cluster:

The right pin is going to be connected to the switch choosing between kmph/RPM, the left pin (connected to the push button) selects the value to be put out.

Once assembled it's a quick and easy way to calibrate:

That's how it looks like after calibration:

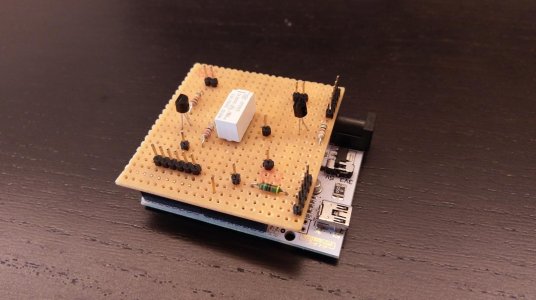

In addition, instead of an Aruino Uno we need a Freaduino as the 12 V power supply from the cluster is regulated down to 5 V and the original Arduino uses a linear voltage regulator to do that. It can take a maximum of 1 W. Unfortunately, the full setup takes 180 mA from at 15 V power supply (worst case) which means 180 mA @ 10 V are creating heat at the linear voltage regulator: 1.8 W - too hot to touch.

The Freaduino on the other hand has a switching power supply that can easily handle this task resulting in a mere 87 mA @ 15 V - pretty much ignoring the higher voltage and everything stays cool.

As for now, I'm playing with the resistors needed for the smaller gauges - unfortunately they need a rather high wattage so there is going to be another parts order, I'm afraid ..

One more day of unpaid holidays to work on the "Kalibrator":

Circuit update - a pull-down resistor for the push-button was missing and a little clean-up:

Corresponding PCB update - luckily no big change:

Looking at the first prototype PCB decided to make a new one, incorporating all the changes:

Then a few hours of programming to add button debouncing, Button, LED and signal generator control, start up check, cleaning up the code, etc.

All finished with a first test run connected to the gauge cluster:

As it's just have the fun with anything moving, here's a short clip with the uncalibrated cluster:

The right pin is going to be connected to the switch choosing between kmph/RPM, the left pin (connected to the push button) selects the value to be put out.

Once assembled it's a quick and easy way to calibrate:

- Choose highest value and tune the top range potentiometer for a match

- Jump to the lowest value and tune the low range potentiometer

- Check highest value again and re-tune top range if necessary

- Check all values for a match

That's how it looks like after calibration:

In addition, instead of an Aruino Uno we need a Freaduino as the 12 V power supply from the cluster is regulated down to 5 V and the original Arduino uses a linear voltage regulator to do that. It can take a maximum of 1 W. Unfortunately, the full setup takes 180 mA from at 15 V power supply (worst case) which means 180 mA @ 10 V are creating heat at the linear voltage regulator: 1.8 W - too hot to touch.

The Freaduino on the other hand has a switching power supply that can easily handle this task resulting in a mere 87 mA @ 15 V - pretty much ignoring the higher voltage and everything stays cool.

As for now, I'm playing with the resistors needed for the smaller gauges - unfortunately they need a rather high wattage so there is going to be another parts order, I'm afraid ..

Last edited: