So I can qualify as much information as possible (I know there is going to be some questions) I will lay out my system and concerns.

I've followed with keen interest the research done by RYU and LMR with their water only setups on their Comptech Superchargers and have recently purchased one. But before install, I need some thoughts on install because I have found different lines of thought on placements. So here goes with the questions;

So what do you think?

- 1997 NSX-T 3.2

- AEM Series II stand alone EMS

- AEM wide band UEGO O2 sniffers

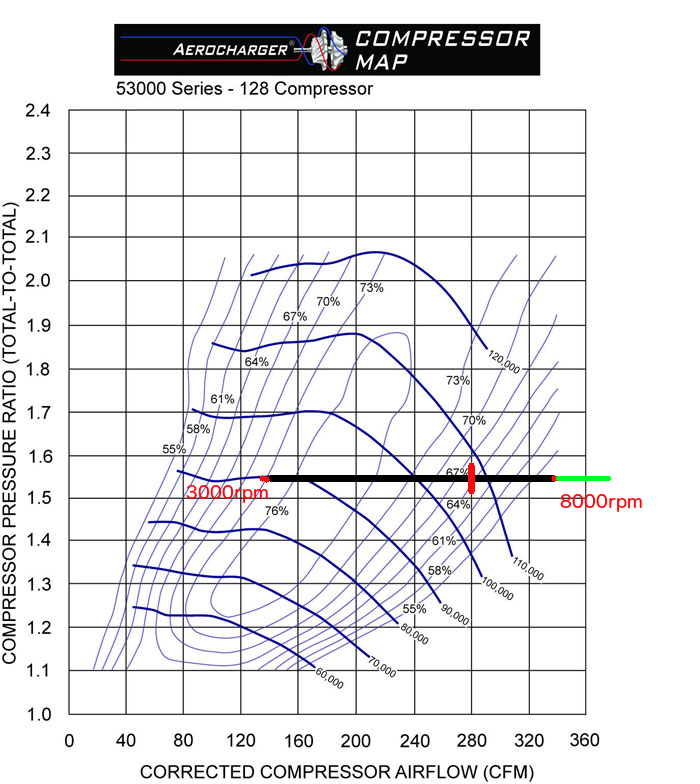

- Twin Areodyne 55 series variable vane turbos with single port adjusters and blow off valve

- Corky Bell cold side intake with ATA intercoolers behind the rear tires (one per side)

I've followed with keen interest the research done by RYU and LMR with their water only setups on their Comptech Superchargers and have recently purchased one. But before install, I need some thoughts on install because I have found different lines of thought on placements. So here goes with the questions;

- I have the one gallon resevoir with the fail safe, low level indicator and trip if I do run out of fluid.

- I would like to mount this under the front hood where the spare tire used to live. Any issues with this remote location? I need the trunk space as my wife packs lots of shoes!

- I know this can be wired up off the EMS to flow juice at whatever desired rpm/boost I want. I'm thinking of 2psi or setting it off IAT, independent. Thoughts?

- Now here is where it gets crazy, I've researched where some folks suggest adding the water/meth pre-turbo(s) at the inlet to cool the charged air at the source of it getting hot. Some say "stay away" and add pre throttle body. I've even read where some say you can add pre turbo and a secondary driver can add more pre throttle body as needed!

- I'd like to stay with water only but my tuner suggests going 50/50 as I won't have to worry about a hazard with going with straight meth and the added cooling feature. I'd like to stay with water only. Thoughts here?

So what do you think?

Last edited: