I've been reading through the forum but need some guidance for 1994.

-In 2012 I had BrianK repair my CCU.

-2 weeks ago I had my AC Freon refilled before summer started. However, in April & May, I noticed when I turned on the CCU sometimes it would take a few minutes before it would start blowing either hot air or AC.

-My CCU turns on, all buttons & lights work but no air is blowing. I can hear things turning off or on if I switch from 18c to 32c. I can hear vents moving when switching the air vent direction.

-When I did the CCU self test & pressed both buttons on my climate unit, the only thing that came on was "MODE"?

I checked the 30amp fuse under the hood in the larger more squarish (not rectangular box) & it looks fine.

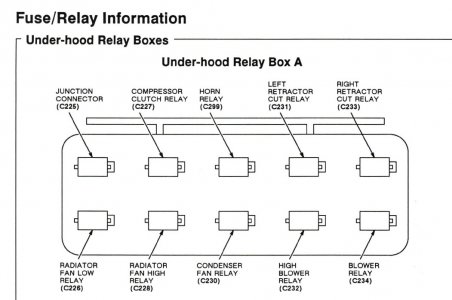

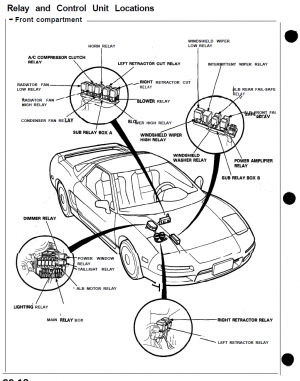

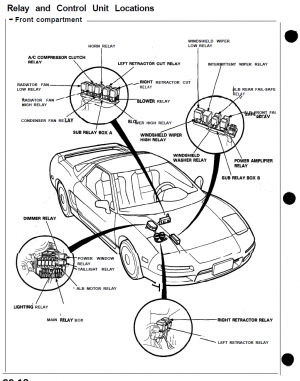

Here's where I need help. After some reading, it seems as though the layout of the under hood firewall Realy boxes are different for 97+.

It was suggested to use this picture from the service manual

My fuse box actually has a melted fuse on the bottom right. It seems like this fuse is blower relay?

Once that fuse box is cleaned up, which relay would I be buying to replace that melted one?

39794-SL0-004?

The diagram is unclear to me on online parts websites.

www.oemacuraparts.com

www.oemacuraparts.com

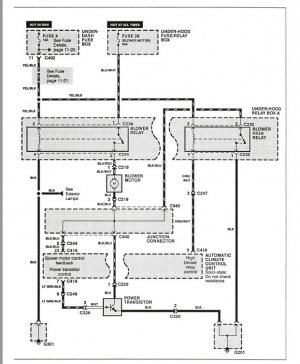

It also seems like I need to check the voltage going to the blower motor. I found old posts & the pictures are gone. Anybody have a picture of what wires/connections I need to check?

-In 2012 I had BrianK repair my CCU.

-2 weeks ago I had my AC Freon refilled before summer started. However, in April & May, I noticed when I turned on the CCU sometimes it would take a few minutes before it would start blowing either hot air or AC.

-My CCU turns on, all buttons & lights work but no air is blowing. I can hear things turning off or on if I switch from 18c to 32c. I can hear vents moving when switching the air vent direction.

-When I did the CCU self test & pressed both buttons on my climate unit, the only thing that came on was "MODE"?

I checked the 30amp fuse under the hood in the larger more squarish (not rectangular box) & it looks fine.

Here's where I need help. After some reading, it seems as though the layout of the under hood firewall Realy boxes are different for 97+.

It was suggested to use this picture from the service manual

My fuse box actually has a melted fuse on the bottom right. It seems like this fuse is blower relay?

Once that fuse box is cleaned up, which relay would I be buying to replace that melted one?

39794-SL0-004?

The diagram is unclear to me on online parts websites.

Control Unit (1) for 1994 Acura NSX | OEMAcuraPart

It also seems like I need to check the voltage going to the blower motor. I found old posts & the pictures are gone. Anybody have a picture of what wires/connections I need to check?

Last edited: