-

***Text Box Error UPDATE*** Folks- we were able to fix the underlying issue with the missing text box on the forum. Everything should be back to normal. - Honcho

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S2k rack on NA1

- Thread starter nsxmugen

- Start date

- Joined

- 7 January 2020

- Messages

- 1

Nice work, a customer of ours wants this conversion done we'll definitely be in touch!

- Joined

- 30 December 2002

- Messages

- 232

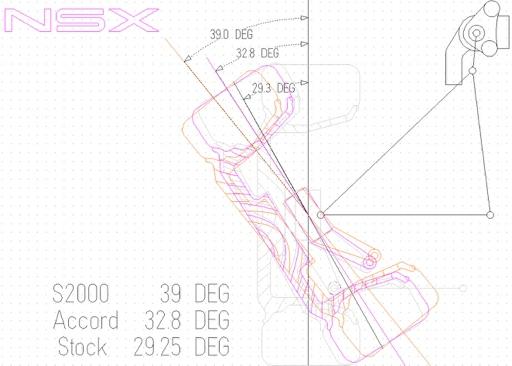

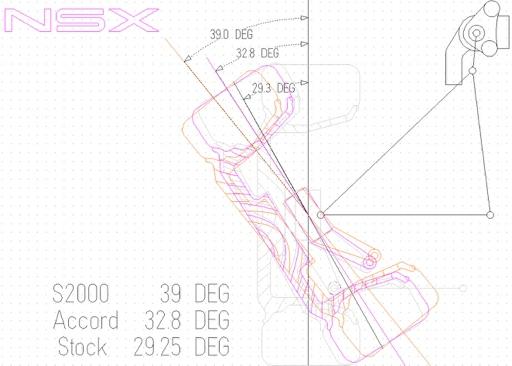

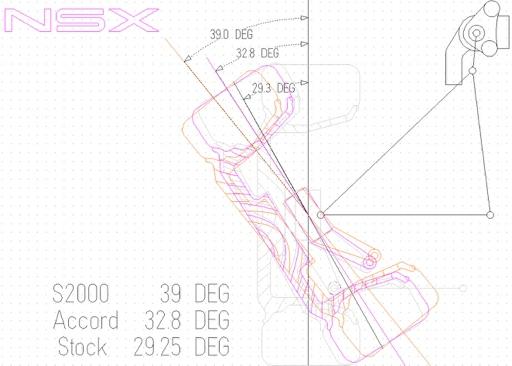

Sounds good. It’s been cold outside and I have not been doing too many things so I wanted to compare the turning radius of the different racks.

Here is what I come up with. The S2000 steering rack has the widest turning radius.

Sent from my iPhone using Tapatalk Pro

Here is what I come up with. The S2000 steering rack has the widest turning radius.

Sent from my iPhone using Tapatalk Pro

ok! So I wasn't imagining it after all!Sounds good. It’s been cold outside and I have not been doing too many things so I wanted to compare the turning radius of the different racks.

Here is what I come up with. The S2000 steering rack has the widest turning radius.

Sent from my iPhone using Tapatalk Pro

- Joined

- 22 November 2014

- Messages

- 77

Looking at the angles, do you mean the S2000 has the tightest turning radius? Widest would mean you lose steering angle right?

- Joined

- 30 December 2002

- Messages

- 232

Correct :smile: The wheels turn more so to make a K turn for example it will make it faster.Looking at the angles, do you mean the S2000 has the tightest turning radius? Widest would mean you lose steering angle right?

that additional 10 degrees actually feels more useful in real life than the mere 10 deg might suggest.

Does not help when the tire hits the chassis at full lock.

I think your wording was a bit unfair but I know what you're saying. As you know, rubbing is dependent on so many factors of which can be mitigated. My setup does not rub at all, for example.

Does not help when the tire hits the chassis at full lock.

- Joined

- 30 December 2002

- Messages

- 232

Does not help when the tire hits the chassis at full lock.

It was tested and the S2000 steering rack have custom bump stop so nothing like that could ever happen unless car is on air suspension and then anything is possible as lifting the car puts it out of specs and pulls or pushes on the toe depending on the height of the air suspension but the same would apply to oem rack with air suspension.

It was tested and the S2000 steering rack have custom bump stop so nothing like that could ever happen unless car is on air suspension and then anything is possible as lifting the car puts it out of specs and pulls or pushes on the toe depending on the height of the air suspension but the same would apply to oem rack with air suspension.

Hi NSXMugen

I would like to get information on one of your steering rack kits for one of our clients

Please could you email me at [email protected]

Thank you

Joe

- Joined

- 30 December 2002

- Messages

- 232

Hi NSXMugen

I would like to get information on one of your steering rack kits for one of our clients

Please could you email me at [email protected]

Thank you

Joe

Done, send you an email

Sent from my iPhone using Tapatalk Pro

Done, send you an email

Sent from my iPhone using Tapatalk Pro

I’ve replied

Hi i like to purchase a kit can you please email me at [email protected]

- Joined

- 30 December 2002

- Messages

- 232

It's been some time and after deciding not to pursuit for a module to adjust the power assist, I found this page modifry.com that looks like a potentiometer that will adjust power assist. The second diagram is just crazy, this is to control the car with potentiometer instead of steering wheel but the first diagram looks doable.

I'm going try to test this, but does anyone know where to buy 2 gang 100 ohm potentiometer? I got so excited finding the part on mouser but then read that the part is discontinued.

I'm going try to test this, but does anyone know where to buy 2 gang 100 ohm potentiometer? I got so excited finding the part on mouser but then read that the part is discontinued.

Last edited:

This one looks like it should work: https://www.mouser.com/ProductDetail/Bourns/3549S-2AB-101-101A

It's worth noting that the circuit shown on the modifry website is just using the pots like a standard resistor. Once you get the power assist dialed in you could measure the resistance at the pot and then replace it with 2 standard resistors of the same value for a more permanent, simple solution.

It's worth noting that the circuit shown on the modifry website is just using the pots like a standard resistor. Once you get the power assist dialed in you could measure the resistance at the pot and then replace it with 2 standard resistors of the same value for a more permanent, simple solution.

Last edited:

- Joined

- 30 December 2002

- Messages

- 232

This one looks like it should work: https://www.mouser.com/ProductDetail/Bourns/3549S-2AB-101-101A

It's worth noting that the circuit shown on the modifry website is just using the pots like a standard resistor. Once you get the power assist dialed in you could measure the resistance at the pot and then replace it with 2 standard resistors of the same value for a more permanent, simple solution.

Good idea, having something predetermined would be better then turknob that can be the weakest link over time. But how can the resistance be reduced with a resistor? I thought the resistor increases the resistance. The resistance of the torque sensor coil 1 goes up and the resistance of coil 2 goes down simultaneously when making a left turn for example and vice versa when making right. I'm thinking adding same resistor would just move the initial point of resistance and not make a difference? Maybe that is why the modifry used 2gang potenciometer?

Thanks!

This is the circuit used to just adjust the power assist.

When no torque is applied, there is a uniform amount of current flowing into VS1 and VS2, and when you turn the wheel these currents change and the EPS unit uses the current differential to determine how much assist to apply. The potentiometers are wired up as simple variable resistances in between the torque sensor and the EPS unit so that the currents are reduced uniformly, causing the differential to be smaller, causing overall less power assist to be applied for a given torque on the steering wheel.

The reason a 2 gang potentiometer is used is so that the resistance will be identical on both VS1 and VS2. If the resistances are different then the currents would be different causing the EPS to apply assistance even when you aren't turning the wheel, which is how the 2nd steer by potentiometer circuit works.

When no torque is applied, there is a uniform amount of current flowing into VS1 and VS2, and when you turn the wheel these currents change and the EPS unit uses the current differential to determine how much assist to apply. The potentiometers are wired up as simple variable resistances in between the torque sensor and the EPS unit so that the currents are reduced uniformly, causing the differential to be smaller, causing overall less power assist to be applied for a given torque on the steering wheel.

The reason a 2 gang potentiometer is used is so that the resistance will be identical on both VS1 and VS2. If the resistances are different then the currents would be different causing the EPS to apply assistance even when you aren't turning the wheel, which is how the 2nd steer by potentiometer circuit works.

Would you mind sending me some info on the kit? My email is [email protected]. Thanks!

After a short time of installing the S2K rack in my NSX it was down for almost a year until recently. Now that it's back on the road and the "new-ness" of the rack has worn off I have some initial thoughts to share.

BTW - I WOULD LOVE ADDITIONAL POWER ASSIST AT PARKING LOT SPEEDS (UNDER SAY 15MPH) :biggrin::biggrin: I can output a few different signals from my HKS ECU to help control this as a bonus and if needed.

Impressions after a year in hibernation and a quick back to back with a stock 94 NSX this week.

In closing, there is definitely some pros and cons here. It just depends what you prioritize more.

BTW - I WOULD LOVE ADDITIONAL POWER ASSIST AT PARKING LOT SPEEDS (UNDER SAY 15MPH) :biggrin::biggrin: I can output a few different signals from my HKS ECU to help control this as a bonus and if needed.

Impressions after a year in hibernation and a quick back to back with a stock 94 NSX this week.

- On-center feel is muted. By how much? I can't quantify that but it's not enough to bother me. Yes, some people call it the "dead" feeling

- Quick ratio has been the biggest benefit. To me, the car does not feel "darty" at all. My accuracy in placing the car has improved a lot. It also doesn't feel "twitchy" at least to me.. but i've also adjusted my suspension to better compensate for body roll... it's been a positive improvement all around.

- Bump Steer - I don't feel much if any but i've also raised my car about .5-.75" higher. Someone else can comment on this? @Boostedtaco? Looking at the geometry of the new rack, it seems bumpsteer should improve.

- EPS is much welcomed in pretty much all low speed situations.

- That manual rack finger touch resolution in feel is definitely attenuated in slow, sweeping corners, but you gain control in the tight and fast stuff.

- I don't miss that OEM lack of control at tight steering angles because the steering wheels becomes too heavy to muscle back. In other words, I feel like I have much better control of slip angle. It's certainly quicker to recover with better resolution through your arms here. I have NOT yet had a track day though!!!

- I haven't tried anything wider than 215 tires yet. I think I can fit 245s and I'm so eager to try...

- As mentioned above, I'd love more slow speed assist as a point to knit pick on... However, my driveway requires a 3pt turn and it's been a joy leaving the house

- I don't have any desire to put back my manual rack but i'm not selling it.

- My main complaint about the AP1/CR rack is the lack of initial assist right as you start to turn the wheel. That initial tug at the steering wheel. The assist doesn't come online until a bit of effort is exerted to turn the steering wheel. If I was fine tuning this as an OEM, i'd add a bit more of initial assist. Max assist or overall assist torque is good. Don't need any more of that. It's just the initial that needs a lower ramp up starting point... if that makes any sense. @stuntman can probably describe this better once he tries it.

- After trying the stock OEM steering rack.. there is definitely some magic that I miss but in a car that is even mildly modified it becomes overbearing in many situations for an avg driver like me

In closing, there is definitely some pros and cons here. It just depends what you prioritize more.

Last edited:

After a short time of installing the S2K rack in my NSX it was down for almost a year until recently. Now that it's back on the road and the "new-ness" of the rack has worn off I have some initial thoughts to share.

BTW - I WOULD LOVE ADDITIONAL POWER ASSIST AT PARKING LOT SPEEDS (UNDER SAY 15MPH) :biggrin::biggrin: I can output a few different signals from my HKS ECU to help control this as a bonus and if needed.

If using resistors to reduce the current signal applied to VS1 and VS2 works, a step assist control type of function would be exceedingly easy to implement if your HKS can generate digital outputs based on vehicle speed. These outputs could drive relays (through an interposing transistor) which would short out resistors in a series resistor tree in each VS1 and VS2 signal line, much like the fuel pump relay shorts out the fuel pump resistor for additional fuel flow on the NSX. If you had two 10 ohm resistors you could arrange it so that both resistors are shorted out below 20 km/hr giving max assist. At 21 km/hr one relay would open inserting 10 ohms into the circuit reducing assist. At 80 km/ hr the second relay opens inserting the 2nd resistor raising the total resistance to 20 ohms and going to minimum assist. You could alter the assist levels by adjusting the resistors ohms and the transition levels by reprogramming your HKS. If you have more outputs available on your HKS you can have more levels of variable assist.

If you can't generate digital outputs with your HKS, a speed based pulse signal from any source could be fed to a one board controller and with a little coding the controller could be used to control the resistor shorting relays. Once you have made the transition to using an out board one board controller with a speed input you could use it to drive a digitally switched resistor bank to give you a (insert the number of control steps you want) signal that is a function of vehicle speed based upon a user set assist map. You might be able to make the transition to a true digital potentiometer which could make the controller tiny; but, I am not sure that they come in the right resistance ranges or the current handling capability for this particular application.

Of course, the preceding assumes that the maximum assist with 0 ohms resistance is adequate for your parking lot maneuvers and what you want is less assist at higher speeds. If the current arrangement with no speed signal to the AP1 rack does not provide enough low speed assist, the variable resistor is not going to help with that. The S2K rack in its original application gets a VSS signal from the ECU. Did you implement that or are you running it in some kind of fail safe mode without a VSS signal?

Last edited:

I am not at all familiar with the details of the NSX R final drive. If your primary concern is the error in the speed signal for the EPS caused by the change in the final drive ratio I personally would not be overly concerned. The change in drive ratio will mean that the pulse / mph is higher than with the standard final drive so the EPS receives a speed signal that is higher than true speed (the % error being the difference between the drive ratios). This should cause the EPS assist to taper off faster than normal which some people might view as a desirable feature.

Just for good measure, the 97+ EPS unit has two speed signals. VSS1 comes off the same VSS sensor as is used for the speedometer and ECU. VSS2 comes from the pulse unit from the differential mounted sensor. For double good measure, the VSS pulse rates for the two signals as measured at the terminals to the EPS control unit are different. According to the service manual VSS2 is 50 pulses per revolution and VSS1 is 4 pulses per revolution (presumably revolution refers to a revolution of the rear wheels). The service manual is not clear on what the EPS does with the two signals other than generating an error code if there is a discrepancy in the derived speed signal between the two. Perhaps it defaults to a minimum assist level?

I know physically where the VSS1 and VSS2 sensors are located - pretty much side by side on top of the differential housing. VSS1 is a mechanically driven hall / opto sensor (I am guessing that the drive is right off the final drive gear) and VSS2 appears to be a 'tooth counting' variable reluctance sensor (it only has two wires) presumably sensing the teeth on the final drive gear (or is there a separate tone ring?). Presuming that both VSS devices get their signal off of the final drive gear the speed error caused by the change in final drive ratio will be consistent and should not cause any error codes for the EPS. In such case the only change is that the assist may taper off faster.

If the problem is that the VSS2 sensor no longer works with the NSX-R final drive because of an absence of a tone ring (or whatever reason), that is a bigger problem. In such case, if you really want an NSX R final drive I would be inclined to try to fake the VSS2 signal by picking up the VSS1 signal and writing some pulse multiplier code for an Arduino that could then generate the higher frequency VSS2 signal. This will work just fine for steady state speeds. While changing speeds there will be a short time lag between the calculated VSS2 signal and VSS1 which creates a potential speed error between the two which might trigger an error code depending on the EPC speed error threshold. A GPS receiver with separate controller could generate the VSS2 signal and presumably do it fast enough to avoid generating speed mismatch error codes in the EPS.

However, GPS units are not without issues. I have a GPS speedometer on another car and I know that there are certain times of the day that signal acquisition can take minutes, presumably because of the available constellation of satellites. Once acquired, I have never lost the signal as long as I stay out of well shielded structures and tunnels. One additional problem is that the GPS based system is not affected by tire size. If you change your rear tire size this cause an error in the VSS1 signal while the VSS2 signal remains true which then creates the potential for a EPS error code. The faked VSS2 signal from the VSS1 sensor would not suffer from this tire size change error.

Not being familiar with NSX R stuff, the higher ratio final drive creates a potential problems for the speedometer on the R. Does the NSX R use a different VSS1 sensor to give a correct pulse rate or does it use a speedometer that has a different calibration to work with the different pulse rate associated with the NSX R final drive?

Just to add to this if anyone in the future is wondering, the NSX-R 4.23:1 final drive works just fine with the early EPS systems (pre 1997?). Will not work with the later spec EPS racks for whatever combo of reasons.

I ran into this because I converted my A/T car to M/T and retrofitted the NSX-R final drive ring gear as well. To keep EPS working, I added a stock VSS2 sensor to the blanking plate hole already on the manual transmission to pick up the signal from the ring gear teeth and added one small 10mm spacer washer to the sensor bolt.

The spacer (standard 10mm bolt washer) is required because the ring gear will hit the tip of the VSS2 sensor and eventually it will grind away the tip and throw EPS errors. The sensor has a small window where it will actually pick up signal. No spacers will kill the sensor, one spacer works perfectly, two spacers will throw an EPS code since the sensor doesn't get good signal. I think this is the reason why some people reported the EPS not working after their 4.23 swap before it was discovered that a spacer was required.

That said, I didn't really notice a difference in EPS assist with a stock A/T or with a 4.23 FD M/T. Perhaps the assist falls off a bit quicker than with a stock 4.06 FD but not enough for me to notice. Basically, all you need for this to work is to add a spacer to your VSS2 assuming you already have a manual transmission.

Something related to the actual thread topic, if one was to retrofit an S2K rack onto a RHD NSX, would they need to get a USDM/LHD S2K rack and flip it like you did with a RHD rack? How involved is the whole retrofit? What are some ballpark costs for everything needed?

Last edited:

- Joined

- 30 December 2002

- Messages

- 232

"Old Guy" as always thanks for your input, that is great explanation and awesome resolution using the relays. Using relays like you explain should work. I have my 2pot potentiometer build with jump harness to test it I just did not have time to test it for weeks now.

"Big McLargeHuge" Correct, for the RHD nsx it will need USDM/LHD rack. I have not done that but I can only assume it would be just flipping the dimensions of crossmember to right side. The location of the hole in the floor from steering column should just be flipped. The good thing is that there is plenty of USDM/LHD S2000 rack out there on the market. I'll send you PM with more info.

"Big McLargeHuge" Correct, for the RHD nsx it will need USDM/LHD rack. I have not done that but I can only assume it would be just flipping the dimensions of crossmember to right side. The location of the hole in the floor from steering column should just be flipped. The good thing is that there is plenty of USDM/LHD S2000 rack out there on the market. I'll send you PM with more info.

I've read through your thread with great interext as I believe the steering on the NA1 is it's weakest point compared to more modern cars.

Given that Porsche cars are highly rated in terms of steering feel, I was wondering if you had contemplated using a steering rack say from a Boxster?

It's also positionned in front of the front axle but it's easy to find racks from the UK and turn them around.

The first models were 100% hydraulic but later models became electrically assisted.

What do you think about the idea?

Given that Porsche cars are highly rated in terms of steering feel, I was wondering if you had contemplated using a steering rack say from a Boxster?

It's also positionned in front of the front axle but it's easy to find racks from the UK and turn them around.

The first models were 100% hydraulic but later models became electrically assisted.

What do you think about the idea?

Similar threads

- Replies

- 15

- Views

- 376