My 29,000 mile 2005 car recently had timing belt and water pump service done. A short while later my car has started to misfire. Reading the codes I get P1387. "Cylinder position sensor intermittent operation". Did someone fuck something up?

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Timing belt changed, now getting cylinder sensor code. Related?

- Thread starter TURBO2GO

- Start date

Maybe yes, maybe no. I can't remember where it is; but, check the plug for the CKP/CMP sensor. Maybe the plug got fiddled with and didn't get re seated completely. Its also possible that the wires got pinched and damaged during work on the car. It is also possible that the sensor is failing. I recall that the sensors sometimes develop an ooze and look like crap; but, I don't recall that this actually results in failure.

I recall that the sensors sometimes develop an ooze and look like crap; but, I don't recall that this actually results in failure.

I agree, I have seen these oozing all the time, but typically does not lead to failure. The plug is located on the top passenger side of the front valve cover, under the black plastic piece that the 02 sensor wires are under(just to the right of the alternator, if you are looking from the passenger side). You will need to remove the coil cover for the front valve cover, then the bolt that holds the small cover over the wiring harness. The plug in question does have to be moved to get the front valve cover off, but typically I do not need to unplug it. In the 1991 service manual online, page 11-46 shows the connector. Even though yours is a 2005 the connector is located in the same place.

If all this looks fine, I suggest a compression test to confirm the timing belt has not jumped a tooth. I would rule that out, once you confirm the connector is OK. Also have you reset the ECU? Is this issue repeatable after an ECU reset?

HTH,

LarryB

Last edited:

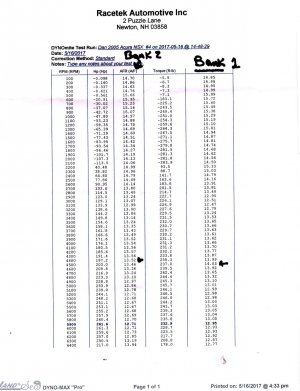

Thanks... I have reset the ECU and the misfire remains but I only read codes once. I reset it by pulling the fuse. I will read codes again after I clear it. The misfire is strange. It is not like an ignition related misfire. Off the like at full throttle the car hesitates a little like it is running rich... then it backfires... POP.... and sometimes a second one... POP.... then it seems OK... it doesn't sputter, it doesn't increase misfire with RPM like ignition related misfires do. Feels like fuel.... yet that is the code I get. I have two codes now... one is "lean bank 1" P1701, and the other new one is this. I have ordered an adjustable fuel pressure regulator from AEM. The dyno AFR readings show slightly lean. Fuel pressure rock solid at 55. Both banks read identical AFR. A bit on the lean side. Engine is stock now other than headers, and cat bypass pipes, and a uni filter. Found no vacuum leaks. Tested with smoke. I plan to raise fuel pressure a little and check readings again. I can't figure out why it is lean.

Attachments

Last edited:

First off, the engine uses a MAP sensor not a MAF sensor, so air leaks into the manifold will not result in lean operation, just high idle speeds (an air leak just looks like a slightly open throttle plat on a MAP system) which the ECU will attempt to correct with the DBW.

The dyno runs would normally be done at WOT. Typically the ECU is running open loop (no correction from the O2 sensors) under those conditions. The AFRs that you measure in a dyno run are not an indication of what the AFRs are at other operating points. You said the engine is stock. Does that mean the CTSC is no longer? Even if you still have the CTSC, unless you have a previous dyno run with which to make a comparison, your WOT AFRs don't seem that bad

My opinion - if your fuel pressure tests out OK, I would not try to fiddle the pressure to alter the AFRs. If you are running an original ECU, when you jack up the fuel pressure to increase the injector flow rate, when the ECU is operating in closed loop it is going to reduce the injector pulse width to try to bring the AFRs back to target. This can lead to things like poor idle if you enter the injectors non linear flow regimen. It can also generate more codes if the ECU can't bring the AFR to target.

You may not have CKP/CMP problem. If you are running lean and getting lean back fires, sometimes the momentary rapid change in RPM can cause the ECU to interpret the RPM changes as a CKP/CMP problem. I have no direct experience with this on the NSX (knock on aluminum - the NSX has never generated a code); but, when my son first got his RSX, his use of the clutch was not always 'smooth'. On one occasion, he did one of those lurch, go, lurch, go, stall moves. On restart, his MIL was lit up. Pulling the code indicated that it was a CKP/CMP problem caused by the RPM fluctuations during his lurch - go moves. Reset the code and the problem never returned - because he worked on his clutch skills. short answer, your CKP/CMP may be just fine and the code you got was a symptom of other problems.

I would focus on fuel delivery first (but leave the fuel pressure alone for now). I could go with a dirty injector; however, if you are getting lean codes on both cylinder banks that means dirty injectors on both banks all of a sudden, which seems odd unless you got into a batch of bad fuel.

The dyno runs would normally be done at WOT. Typically the ECU is running open loop (no correction from the O2 sensors) under those conditions. The AFRs that you measure in a dyno run are not an indication of what the AFRs are at other operating points. You said the engine is stock. Does that mean the CTSC is no longer? Even if you still have the CTSC, unless you have a previous dyno run with which to make a comparison, your WOT AFRs don't seem that bad

My opinion - if your fuel pressure tests out OK, I would not try to fiddle the pressure to alter the AFRs. If you are running an original ECU, when you jack up the fuel pressure to increase the injector flow rate, when the ECU is operating in closed loop it is going to reduce the injector pulse width to try to bring the AFRs back to target. This can lead to things like poor idle if you enter the injectors non linear flow regimen. It can also generate more codes if the ECU can't bring the AFR to target.

You may not have CKP/CMP problem. If you are running lean and getting lean back fires, sometimes the momentary rapid change in RPM can cause the ECU to interpret the RPM changes as a CKP/CMP problem. I have no direct experience with this on the NSX (knock on aluminum - the NSX has never generated a code); but, when my son first got his RSX, his use of the clutch was not always 'smooth'. On one occasion, he did one of those lurch, go, lurch, go, stall moves. On restart, his MIL was lit up. Pulling the code indicated that it was a CKP/CMP problem caused by the RPM fluctuations during his lurch - go moves. Reset the code and the problem never returned - because he worked on his clutch skills. short answer, your CKP/CMP may be just fine and the code you got was a symptom of other problems.

I would focus on fuel delivery first (but leave the fuel pressure alone for now). I could go with a dirty injector; however, if you are getting lean codes on both cylinder banks that means dirty injectors on both banks all of a sudden, which seems odd unless you got into a batch of bad fuel.

yeah original 05 with 30,000 miles. CTSC was removed long ago. The pop is on hard acceleration in first not on a change in throttle position. I have been driving manuals for 25 years and on the track for 10, I heel and toe, double clutch and rev match, so I think my use of clutch is OK. I am nearing 14 on AFR you don't think that is too lean? The dyno run was at WOT but he was letting off around 6K. I thought the change in exhaust and intake may be causing the slight lean mixture. I am baffled. Going back to the shop for some more tests. BTW I used to get this lean code with the CTSC. Frustrated, I removed it. It remains...

Last edited:

- Joined

- 15 May 2004

- Messages

- 6,898

You ARE running leaning up to 4500 rpm. Above 4800 rpm it's ok again. My wild guess is that you have a problem with your fuel delivery, esp. fuel pump. The CTSC system puts a lot of stress on the fuel pump, so it wears out. When you went back to your 'slow stock configuration' (CTSC owners arrogance, I know  ) you most likely reinstalled the fuel switch relay which shifts the fuel pump up at around 4400 rpm. It takes some time/rpm until the fuel supply it at the higher level. Maybe worth to look at.

) you most likely reinstalled the fuel switch relay which shifts the fuel pump up at around 4400 rpm. It takes some time/rpm until the fuel supply it at the higher level. Maybe worth to look at.

I wasn't suggesting that it was your clutch style that was creating the problem, merely noting that an exceedingly fast drop in RPM, whether it is caused by a jerky clutch operation (my son) or a lean backfire could cause the CKP/CMP error code. The fact that you are not triggering any of the ignition misfire codes associated with the misfire detection module on the NA2 engines (which is not fool-proof) suggests that your problems probably are not caused by an ignition system problem and that the fuel system deserves the attention.

Curious about your P1071 code. No such code in the service manual. Did you mean P0171 System Too Lean Bank 1?

goldNSX raises a good point. 47 - 53 psi (50 psi being design) is the specified fuel system test pressure at idle with the vacuum reference line removed from the regulator. The fuel pressure should drop when you re attach the vacuum line. Fuel rail pressure would normally only reach 50 psi under conditions of wide open throttle. Are you logging fuel pressure on the go? If you are logging and the fuel pressure never drops below 50 psi then you don't lack for fuel pressure (you have the opposite problem). If the 50 psi you mentioned is just the idle fuel pressure with the reference line removed and you have the stock system with the fuel pump resistor in place, then perhaps do the fuel pump resistor paper clip by-pass test to see if that cures the lean back-fire and eliminates the codes. It is a super simple test. If it eliminates the problem, then perhaps you have a weak pump.

The service manual says exhaust leakage and excessive valve clearance can trigger a P0171. If the manifold has a leak and is allowing O2 into the manifold upstream of the sensor I can see that. That would normally not cause a lean back fire and it would be a bit odd for it to occur on both banks at the same time. The excessive valve clearance cause has me a bit mystified. Same problem that it would be odd for it to show up on both banks at the same time. However, if a skew in the valve timing could cause the mixture problem, then that is something you could see as a common cause event originating from the belt replacement. However, it is not immediately obvious to me why a valve timing error would cause a mixture out of range lean condition. You would need to get some input from somebody like Larry B or Kaz who has more experience.

Curious about your P1071 code. No such code in the service manual. Did you mean P0171 System Too Lean Bank 1?

goldNSX raises a good point. 47 - 53 psi (50 psi being design) is the specified fuel system test pressure at idle with the vacuum reference line removed from the regulator. The fuel pressure should drop when you re attach the vacuum line. Fuel rail pressure would normally only reach 50 psi under conditions of wide open throttle. Are you logging fuel pressure on the go? If you are logging and the fuel pressure never drops below 50 psi then you don't lack for fuel pressure (you have the opposite problem). If the 50 psi you mentioned is just the idle fuel pressure with the reference line removed and you have the stock system with the fuel pump resistor in place, then perhaps do the fuel pump resistor paper clip by-pass test to see if that cures the lean back-fire and eliminates the codes. It is a super simple test. If it eliminates the problem, then perhaps you have a weak pump.

The service manual says exhaust leakage and excessive valve clearance can trigger a P0171. If the manifold has a leak and is allowing O2 into the manifold upstream of the sensor I can see that. That would normally not cause a lean back fire and it would be a bit odd for it to occur on both banks at the same time. The excessive valve clearance cause has me a bit mystified. Same problem that it would be odd for it to show up on both banks at the same time. However, if a skew in the valve timing could cause the mixture problem, then that is something you could see as a common cause event originating from the belt replacement. However, it is not immediately obvious to me why a valve timing error would cause a mixture out of range lean condition. You would need to get some input from somebody like Larry B or Kaz who has more experience.

- Joined

- 15 May 2004

- Messages

- 6,898

As Old Guy suggests I'd bypass the fuel resistor and check again. As your car has OBDII you should be able to monitor AFR with an OBD scan gauge directly. Fuel pressure is only one dimension. You actually want to measure the fuel amount at a certain pressure. But that's hard to do under load without equippement. A steady fuel pressure at idle doesn't say much, it would only point to a completely worn out fuel pump or a bad FPR. But the fuel pressure is a useful indicator for the fuel amount when monitored under load. The lower the fuel amount that is delivered from the fuel pump the lower the fuel pressure while the fuel pump is trying to keep the fuel pressure high enough which is well over 55 psi even for a standard NSX.

Clogged injectors are not very likely as the AFR values are ok above 4800 rpm. A clogged fuel filter is not very likely for the same reason. Anyway: when did you change it? What fuel pump are you running? Still the OEM one? Did you use the Comptech boost-a-pump electronics? This and the high pressure 80-90 psi are even harder on any fuel pump.

With a TB/WP job the valve adjustment is normally done too. That's also not very likely if it has been done correctly. If the TB is one teeth off you can check with an emission test. One teeth off = high HC.

Clogged injectors are not very likely as the AFR values are ok above 4800 rpm. A clogged fuel filter is not very likely for the same reason. Anyway: when did you change it? What fuel pump are you running? Still the OEM one? Did you use the Comptech boost-a-pump electronics? This and the high pressure 80-90 psi are even harder on any fuel pump.

With a TB/WP job the valve adjustment is normally done too. That's also not very likely if it has been done correctly. If the TB is one teeth off you can check with an emission test. One teeth off = high HC.

As your car has OBDII you should be able to monitor AFR with an OBD scan gauge directly.

Not if the ECU is stock. Are you thinking wide band O2 sensors? The OEM O2 sensors are narrowband sensors so the only thing they effectively report to the ECU is that the AFR is below 14.7 or above 14.7 and the ECU uses the switch point in O2 output voltage to keep the AFR right around 14.7 which is where the 3 way catalysts from the 80s and 90s like to be to operate most effectively. When operating in closed loop with narrow band sensors the target AFR is 14.7. Once the engine gets into the high load operating points the ECU typically goes into open loop and at that point you can have AFRs that are less than 14.7 on a stock emissions compliant ECU. Unless you are pedal to the metal, you should expect that during moderate acceleration the ECU is probably operating the engine at close to 14.7 .

At best, if the Honda ECU makes the O2 sensor voltages available at the OBD2 port, I think the only definitive thing that you could determine is that the AFR is above or below 14.7. Because the response curve of typical narrowbands is so flat you likely would not be able to distinguish 14.8 from 15.1.

Last edited:

- Joined

- 15 May 2004

- Messages

- 6,898

Uuups, sorry I was recalling my last OBDII session in my Insight which has a wideband sensor from the factory. You're right, the NSX has only narrowband sensors with the stock ECU.Not if the ECU is stock. Are you thinking wide band O2 sensors?

Thank you for the replies, I have not read them all in detail yet as I am dead tired at the moment but I have questions I will ask about it all. I just wanted to give a quick update. Installed AEM fuel pressure regulator and raised it around 8 PSI. I put maybe 120 miles on the car, the lean code is gone so far. Yes, P1701, my typo up top. Car actually ran great for a while and I went to Autox today. I made 4-5 runs, no problems. About the 6th run, the misfire came back on hard acceleration in first. I read the code. P1387. No lean codes present. I erased the code with my code reader to see if it comes back. It misfired the next run. CEL came on, I read the code, P1387 again. On the way home, car started to actually hesitate. It would cut in and out but not rapidly. For sure, lots of hesitation, every gear. Then miraculously, sometimes it is just fine. Revs happy. Then it comes back again. I was worried about being stranded it was getting so bad. Each time on acceleration, now even at lower RPM, the car bucks... I made it home and read codes and any pending codes. Still the same P1387. When the mechanic was changing the FPR, he said he disconnected the plug close to the alternator and read the resistance levels on the wires that go to/come from the "cylinder position sensor". He said it looked within spec. The car is becoming undrivable, I certainly cannot autocross it now. I was thinking if checking resistances further up at the ECU or further down at the sensor itself, but that is some serious work. At least the problems isn't so intermittent anymore.

So does this new info change anything in you guys' eyes?

So does this new info change anything in you guys' eyes?

The positive side of that is that the more undriveable your car gets the more likely you'll find the problem.

I'd bypass the fuel resistor first to see if the hesitation at low revs gets better - very simple test.

Rather like the here again gone again toothache that finally decides to check in and stay for the duration.

It is always possible that the CKP/CYP sensor is the cause of you problems. The CKP/CYP sensor actually consists of four sensors in one package. The individual sensors are 2 wire sensors which almost certainly makes them a reluctance type sensor which tend to be dumb-ass reliable. However, the fact that you are consistently getting P1387 does point to just one sensor in the module, the CYP sensor #2 . However, the service manual says that P1387 is no signal versus an intermittent signal, so this may not be the kind of problem induced by lean misfires.

The resistance measurement made by your mechanic is the only diagnostic check available for the individual sensors. The sensor resistance should be 650-850 ohms. The CYP sensor #2 is connected to the orange and orange/blue wires. About the only thing that I can suggest is connect an ohm meter to those two leads in the interconnecting plug and then wiggle the wires and tug on the leads where they enter the sensor module to see if there is a loose connection. Also, check the resistance between the two leads and the engine block. Do this while wiggling and tugging on the wires. The resistance should indicate no connection (infinite). Any indication of a connection to the block indicates an insulation failure somewhere. If the sensor checks out fine, then the next step would be to check the wire harness from the sensor plug back to the ECU which is a whole lot of agony.

BTW I used to get this lean code with the CTSC. Frustrated, I removed it. It remains...

The fuel pump is a wearable item. Yours is 12 YO and it's been stressed with a supercharger for a long time. Before throwing more time, parts, and money at the car, do the simple fuel pump resistor bypass as goldNSX recommended and see if that fixes the problem.

If it doesn't fix the problem, the crank/cam position sensor wiring is most likely your next problem area to check out. Didn't you have two superchargers installed previously? One was bad? So, you've had mechanics doing a lot of work in the loom area where the supercharger and intake manifolds have been added or removed over time. It sounds like a wire has gotten squished somewhere along the line.

Also, keep an eye on the AEM fuel regulator pressure over time to make sure it's the same as you had it originally set. Sometimes the aftermarket setups drift a bit. Maybe 2-3psi, but typically nothing major. Just something else to monitor as you remove old, reliable Honda engineering/parts for aftermarket components. :smile:

I'm probably the worst offender here. Had the most complex FI setup engineered and installed, only to have low-to-moderate load tuning and drivability issues. Sure, at WOT I had 15 psi of boost from 2500 to 7500 RPM, but now I'm trying to use the car more as a fair-weather driver. The engine driveability issues and the SOS twin carbon clutch made it no fun around town. So, no more FI, drysump was removed, etc. Still need to change the clutch....

Last edited:

Even though it sounds like two separate issues, these two may be related as OldGuy explained above.

That's why I would start with the simple test of making the fuel pump run in high speed continuously. It's quick and simple. The problem with pumps is, even though they might give good pressure at low fuel flow rates (idle), they may not be able to supply the flow/pressure when your injectors are open more and sucking down the fuel. Fill the tank with at least 1/4 gal of gas, jumper the pump to run in high speed, and drive it awhile to see if your issues go away. You won't hurt the OEM pump running it in high speed for testing purposes.

That's why I would start with the simple test of making the fuel pump run in high speed continuously. It's quick and simple. The problem with pumps is, even though they might give good pressure at low fuel flow rates (idle), they may not be able to supply the flow/pressure when your injectors are open more and sucking down the fuel. Fill the tank with at least 1/4 gal of gas, jumper the pump to run in high speed, and drive it awhile to see if your issues go away. You won't hurt the OEM pump running it in high speed for testing purposes.

Man you have a good memory.

I'm going to have to show this to my wife.

Similar threads

- Replies

- 6

- Views

- 1K

- Locked

- Replies

- 7

- Views

- 3K

- Locked

- Replies

- 8

- Views

- 3K

- Replies

- 0

- Views

- 3K