-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you guys think of this?

- Thread starter TURBO2GO

- Start date

Looks busy...

What looks busy? I haven't even made it yet. LOL.

Anyway yes it might be "busy" but what it will also be is highly functional.

Sure I can do a quick mockup. If you can get me more dimensions I can make it more accurate which would help you out more. Dimensions of the console (width at the top and width at the bottom of the ashtray, height from that point, spacing around the HVAC to the radio+top+sides, HVAC cutout, panel thickness, gauges, etc and some closer angled shots of both gauge types) would be helpful; I'd measure my own car but its at the other house all covered up.

width at top is 7 7/8", just under the HVAC controls where I would start cutting the second row of ovals. That TOTAL width on console is 7 7/8".

Width at bottom of ashtray where I wouldn't want to go any lower is 6 7/8"

Total height between the two points is abput 6 3/4".

Not sure what you mean by spacing around HVAC, but there is 1/4" of console material at the thinnest part of the oval between the edge of console and the oval "hole"... at it's thinnest part.

There is about a 7/16" bridge or wall between the HVAC hole's bottom and the radio's next cutout, that plastic separating the two parts is about 7/16".

The gauge itself require a 52.4mm hole, I can't get any data on overall width anywhere including the manual but my measurement shows JUST under 2 1/4" total face width. The glass width is 1 13/16".

You wanted angles pics but I just made a video:

<iframe width="420" height="315" src="//www.youtube.com/embed/uHypbMC1qmA" frameborder="0" allowfullscreen></iframe>

let me know if you need something else.

Thanks.

Anyway yes it might be "busy" but what it will also be is highly functional.

This is a point of contention. You argue that it will be "highly functional" but I will argue that it will be utterly dysfunctional. Not that my opinion will sway you one way or the other (and others here have opined my sentiments) but why is it that you believe having a deluge of gauge faces at an non-optimal height and placement, issuing forth countless bits of information a second, while your undivided attention is expected to be on the track in front of you is a good thing? I understand that you have already made the investment into these gauges, but you still have the option to sell them off to other buyers. There are TWO! separate Prime members releasing a much needed AEM remote interface that allow you to control exactly what information you see and how you interact with it! This is HUGE!!! It seems to me that you are determined to get this square peg to fit into a square hole simply because you happened to have purchase a square peg.

Josh, I've already talked about why it matters not that warning gauges be line of sight a bunch of times. I don't want to start sounding like a parrot. These gauges give PROPER warning, something few gauges do IMO, and line of sight simply does not matter because they are all distraction. Only one gauge matters to me on the track, my tach. I don't want to be watching other stuff and if I do want to see something, a clear legible analog gauge is much preferable to a multi-gauge. The functions some suggest I should have line of sight are actually things that should be data logged. I have both Data Logging and peak hold functionality.

What other gauge tells you by color and flash, showing only ONE function, hey things are good... hey things are getting a bit high.... and hey I am flashing at you and buzzing need your immediate attention. There is low warning, low, mid, high, and high warning on a legible analog DEDICATED gauge with peak hold and Data logging. Even triggers on warnings. That is EIGHT different ways of giving you information with a hierarchy built into each gauge and nothing else does that.

I don't have an AEM so that piece you are recommending isn't going to do anything for me. I've used plenty of gauges, and have done days of research and given this weeks of thought. I bet I know more about gauges right now than anyone on this board. I can tell you the ins and outs and good points and weaknesses of EVERY setup.

Your argument of it being dysfunctional isn't something I agree with. Everyone wants a certain look in their car, I am fine with a gauge cluster where my radio was. I much prefer that to the navpod and pillarpod.

Although I appreciate your input, I think we might be beating a dead horse at this point. I truly believe that I have the best setup for my needs. This thread is more aimed at getting these mounted well.

What other gauge tells you by color and flash, showing only ONE function, hey things are good... hey things are getting a bit high.... and hey I am flashing at you and buzzing need your immediate attention. There is low warning, low, mid, high, and high warning on a legible analog DEDICATED gauge with peak hold and Data logging. Even triggers on warnings. That is EIGHT different ways of giving you information with a hierarchy built into each gauge and nothing else does that.

I don't have an AEM so that piece you are recommending isn't going to do anything for me. I've used plenty of gauges, and have done days of research and given this weeks of thought. I bet I know more about gauges right now than anyone on this board. I can tell you the ins and outs and good points and weaknesses of EVERY setup.

Your argument of it being dysfunctional isn't something I agree with. Everyone wants a certain look in their car, I am fine with a gauge cluster where my radio was. I much prefer that to the navpod and pillarpod.

Although I appreciate your input, I think we might be beating a dead horse at this point. I truly believe that I have the best setup for my needs. This thread is more aimed at getting these mounted well.

Last edited:

Do a pole. And if the odds are 4 to 1 against I think you shouldn't do it.

Do a pole. And if the odds are 4 to 1 against I think you shouldn't do it.

LOL.... you guys are acting like I am putting these in YOUR car. Do you realize that photo with the big hole as the radio is how I have been driving for over a year? So that space is useless right now.

Man people put buttons and switches and timers and this and that into their dash. I can't do 6 gauges where my radio was for more information on a car that sees the track? I bought STACK not glow shift.

Last edited:

I say do it. Worst case you don't like it and can always go back to stock. Why ask this question if no one elses opinions matter...

I say do it. Worst case you don't like it and can always go back to stock. Why ask this question if no one elses opinions matter...

If you read my first post, I was wanting help on mounting ideas not to go over my gauge selection process again. I've already had two other threads on this, so I don't want to make things redundant is all.

Yeah I have two consoles so I can go back to stock. Now I'm just waiting for KY650's mockup and I've got my ABS plastic and the glue Stephen advised on ordered. Lets see how it goes.

Josh, I've already talked about why it matters not that warning gauges be line of sight a bunch of times. I don't want to start sounding like a parrot. These gauges give PROPER warning, something few gauges do IMO, and line of sight simply does not matter because they are all distraction. Only one gauge matters to me on the track, my tach. I don't want to be watching other stuff and if I do want to see something, a clear legible analog gauge is much preferable to a multi-gauge. The functions some suggest I should have line of sight are actually things that should be data logged. I have both Data Logging and peak hold functionality.

What other gauge tells you by color and flash, showing only ONE function, hey things are good... hey things are getting a bit high.... and hey I am flashing at you and buzzing need your immediate attention. There is low warning, low, mid, high, and high warning on a legible analog DEDICATED gauge with peak hold and Data logging. Even triggers on warnings. That is EIGHT different ways of giving you information with a hierarchy built into each gauge and nothing else does that.

I don't have an AEM so that piece you are recommending isn't going to do anything for me. I've used plenty of gauges, and have done days of research and given this weeks of thought. I bet I know more about gauges right now than anyone on this board. I can tell you the ins and outs and good points and weaknesses of EVERY setup.

Your argument of it being dysfunctional isn't something I agree with. Everyone wants a certain look in their car, I am fine with a gauge cluster where my radio was. I much prefer that to the navpod and pillarpod.

Although I appreciate your input, I think we might be beating a dead horse at this point. I truly believe that I have the best setup for my needs. This thread is more aimed at getting these mounted well.

Fair enough. I admire your tenacity and committed nature. Also, I was misinformed about what EMS you are running so that is my fault completely. As for the gauges themselves, you bought the best; I don't think anyone can argue with that. Being that an AEM EMS isn't involved here, I am starting to understand your goal.

I went thru another tuning session today. Let me just say... the HKS F-Con iS piggyback is amazing. It almost makes me want to go straight into the VPro because now i'm getting feature hungry and the idea of being able to do this and that is so enticing. I'm going to experiment with the A/F "auto-tune" feature next.

I say this because if you use something like the F-Con iS (which is the only piggyback i'd ever use on the NSX after now knowing what it can do) you may negate the need for all these sensors/gauges unless you want to have redundancy.

I still argue putting so many round gauges in the your NSX center console is a bad idea for multiple reasons but i'm sitting back and waiting for you to amaze me. If anyone can do it, TURBO2GO can!

p.s. why don't you just put it in the glove box and open it when you're at the track.

I say this because if you use something like the F-Con iS (which is the only piggyback i'd ever use on the NSX after now knowing what it can do) you may negate the need for all these sensors/gauges unless you want to have redundancy.

I still argue putting so many round gauges in the your NSX center console is a bad idea for multiple reasons but i'm sitting back and waiting for you to amaze me. If anyone can do it, TURBO2GO can!

p.s. why don't you just put it in the glove box and open it when you're at the track.

For any sensors not available from your OBD2 or if you want to add redundancy you need to add an iF unit + the sensors themselves. Don't ask me how they come up with these ridiculous names but they work.Are you adding sensors to the IS? How would you get oil temp or fuel pressure?

When compared to an FIC the costs add up bigtime though... but if you want the best, well...

http://www.nengun.com/hks/meter-i-f-unit

If you read my first post, I was wanting help on mounting ideas not to go over my gauge selection process again. I've already had two other threads on this, so I don't want to make things redundant is all.

Yeah I have two consoles so I can go back to stock. Now I'm just waiting for KY650's mockup and I've got my ABS plastic and the glue Stephen advised on ordered. Lets see how it goes.

Gotcha.

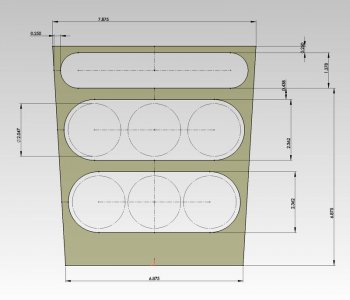

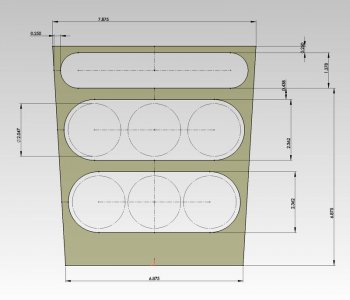

I'm a little fuzzy on your dimensions but here's what I came up with assuming I'm understanding you right. I'm assuming we might be a tad off but it's a good enough ballpark for the sake of conversation at the moment.

If your numbers are about right then I don't see how you're going to fit in a 3rd row of gauges cleanly with concept 1. With the second concept you mentioned I think it would be possible although quite tight. The third option is a hybrid of 1 and 2 where you keep the slotted recess of concept 1 but instead hide the bezel behind your black trim, this way the bezel stays hidden like concept 2 and gives the gauges more breathing room visually. With Concept 1 and 3 you're going to need more than a simple piece of flat ABS with holes in it because you're going to want the lead in to go from the front face of the plastic (silver or black trim facing you) to the gauge's glass, this way it appears as if the gauge never had a bezel. This is going to be a lot more complex fabrication wise just so you know but it would help remove one visual element of the gauges (their bezel) that doesn't match the NSX's stock interior.

Here's a *very* quick model/render of your other idea. If the dimensions are about right then you've got a problem with the fillets (radiused edges) intersecting one another because there isn't enough space. Even if this weren't happening there still isn't really enough space to pull it off IMO. By introducing a third column of gauges you change the issue we were talking about earlier about consistent spacing and the consoles taper, in this instance the change is more noticeable because spacing is tighter horizontally (the fillets are intersecting one another). In the third row with only 2 gauges you have a break continuity with the first 2 rows so theres a question of how do you space them, unfortunately aligning them along the outside or centering them inwards both looks visually awkward.

There's a lot of smaller tricks you can start to play and tweaking of things down to the millimeter that will help refine the design without a doubt (this is a quick stab at things after all), but the underlying issue here is a matter of space constraints. If it were me and I was really set on going this route I would consider exploring the 6 gauge route and pairing it with that 3rd concept option I mentioned earlier. I don't know which of the 8 gauges you consider to be the most important but if it were the 6 that matched each other that would obviously be even more ideal. Just like setting up a good audio system when your constraints are stacked against you (like the NSX cabin) sometimes reaching an ideal is impossible. There unfortunately isn't any way IMO to actually attain an OEM look here but there are ways closer than others; the best you can do is have something that looks thoughtful and considered rather than very DIY. You'll have to decide how you want to prioritize functionality, aesthetics, and fabrication costs here because they're at direct odds with each other here. As always I apologise for being critical here, I simply want to be very up front with the challenges ahead so you're aware of what you're getting into.

Let me know what you're thinking and we can try and explore things in more depth from here.

edit:

I just noticed that you said you measured your gauge diameter at 2.25in or ~57mm - my current model has them at 52mm still which means it's going to be an even tighter fit than those images currently suggest.

If your numbers are about right then I don't see how you're going to fit in a 3rd row of gauges cleanly with concept 1. With the second concept you mentioned I think it would be possible although quite tight. The third option is a hybrid of 1 and 2 where you keep the slotted recess of concept 1 but instead hide the bezel behind your black trim, this way the bezel stays hidden like concept 2 and gives the gauges more breathing room visually. With Concept 1 and 3 you're going to need more than a simple piece of flat ABS with holes in it because you're going to want the lead in to go from the front face of the plastic (silver or black trim facing you) to the gauge's glass, this way it appears as if the gauge never had a bezel. This is going to be a lot more complex fabrication wise just so you know but it would help remove one visual element of the gauges (their bezel) that doesn't match the NSX's stock interior.

Here's a *very* quick model/render of your other idea. If the dimensions are about right then you've got a problem with the fillets (radiused edges) intersecting one another because there isn't enough space. Even if this weren't happening there still isn't really enough space to pull it off IMO. By introducing a third column of gauges you change the issue we were talking about earlier about consistent spacing and the consoles taper, in this instance the change is more noticeable because spacing is tighter horizontally (the fillets are intersecting one another). In the third row with only 2 gauges you have a break continuity with the first 2 rows so theres a question of how do you space them, unfortunately aligning them along the outside or centering them inwards both looks visually awkward.

There's a lot of smaller tricks you can start to play and tweaking of things down to the millimeter that will help refine the design without a doubt (this is a quick stab at things after all), but the underlying issue here is a matter of space constraints. If it were me and I was really set on going this route I would consider exploring the 6 gauge route and pairing it with that 3rd concept option I mentioned earlier. I don't know which of the 8 gauges you consider to be the most important but if it were the 6 that matched each other that would obviously be even more ideal. Just like setting up a good audio system when your constraints are stacked against you (like the NSX cabin) sometimes reaching an ideal is impossible. There unfortunately isn't any way IMO to actually attain an OEM look here but there are ways closer than others; the best you can do is have something that looks thoughtful and considered rather than very DIY. You'll have to decide how you want to prioritize functionality, aesthetics, and fabrication costs here because they're at direct odds with each other here. As always I apologise for being critical here, I simply want to be very up front with the challenges ahead so you're aware of what you're getting into.

Let me know what you're thinking and we can try and explore things in more depth from here.

edit:

I just noticed that you said you measured your gauge diameter at 2.25in or ~57mm - my current model has them at 52mm still which means it's going to be an even tighter fit than those images currently suggest.

Last edited:

KY650 can't thank you enough for the work. Now that I know what measurements you want, I took them more exactly. The height was off, possibly the most important measurement. So I made revisions. Please look at the image:

- - - Updated - - -

One thought I had: Create the ovals (option 1), paint the gauge bezels the same dark silver as my HVAC knobs. You can see the color here:

- - - Updated - - -

One thought I had: Create the ovals (option 1), paint the gauge bezels the same dark silver as my HVAC knobs. You can see the color here:

Hi Dave,

if you are going to butcher a Silver console, can you swap with me??

i send you my Black OEM one first (with Black ashtray cover), as in ASAP (it takes 7 business days to get to you)

and then you send me one of yours (Silver with Silver Ashtray Cover)

What do you say?? :biggrin:

Thanks,

Nuno

if you are going to butcher a Silver console, can you swap with me??

i send you my Black OEM one first (with Black ashtray cover), as in ASAP (it takes 7 business days to get to you)

and then you send me one of yours (Silver with Silver Ashtray Cover)

What do you say?? :biggrin:

Thanks,

Nuno

Last edited:

Hi Dave,

if you are going to butcher a Silver console, can you swap with me??

i send you my Black OEM one first (with Black ashtray cover), as in ASAP (it takes 7 business days to get to you)

and then you send me one of yours (Silver with Silver Ashtray Cover)

What do you say?? :biggrin:

Thanks,

Nuno

I'm afraid you are 2 days late. :redface: I already cut and filed as I was trying to see how the material cuts and glues. Why can't you just paint yours? I don't get the big deal with the silver one.

Hi,

it's hard to mimic the soft finish of the OEM one...usually we have to clear it, and it will

become shinny and hard to the touch, like the outside plastic parts.

and you don't get the big deal because you have one :biggrin:

it's like we wanting all the top notch JDM stuff... and the Japanese want top notch Euro/US stuff:

We always want what it's not easy to get ....

it's a human nature thing i think

Thanks ,

Nuno

it's hard to mimic the soft finish of the OEM one...usually we have to clear it, and it will

become shinny and hard to the touch, like the outside plastic parts.

and you don't get the big deal because you have one :biggrin:

it's like we wanting all the top notch JDM stuff... and the Japanese want top notch Euro/US stuff:

We always want what it's not easy to get ....

it's a human nature thing i think

Thanks ,

Nuno

I didn't have a chance to do any renders but I quickly updated the numbers with your new dimensions. I wouldn't say it changed things as much as I thought it was going to but I'll have to see a side by side comparison to see what it got us. When I get time I'll do a little bit more of a detailed render with some of the ideas mentioned including your bezel concept. I believe I know what the bezels look like from your video but some well lit pictures would still potentially help - getting their look down is going to be important to exploring that option. I'm trying to understand their profile as best I can - this would be ideal if maybe you could draw out a cross section profile like that: http://www.yuenger.com/images/CrownDent1024-07-50%.jpg

I'm not quite sure what you're planning with the plastic sheet and bonding but if I were you I wouldn't bond anything to the trim panel. Ideally you'd replicate the OEM setup where the gauges and the black pieces are mounted to the head unit DIN mounting holes and the trim sits over the part like it does with the radio. If you do that you'll be able to remove the trim a little easier without it being tethered down so much (I thought you mentioned wanting to do this earlier). Aesthetically I don't suppose it makes a difference if you can hold your tolerances (which would be easier to do with the gauges mounted to the trim panel if you're not comfortable with the model making stuff).

As far as making the trim panel itself I think you could get a bit more DIY if you cut the radio section out yourself of the OEM panel, 3d printed/machined (more expensive but more durable) an insert with the cutouts you needed and then bonded the two together. you could install the cut trim panel over the installed gauges with their DIN mount, then place the silver trim insert over them and align it properly, then jig the two parts together to make sure the holes are aligned properly, then remove and bond it all together. Depending on how comfortable you feel with the model making stuff it could be quite reasonable for you to get that silver trim panel together on your own in an unpainted state and then just hand it off to a paint shop to get the last bit of finish needed. This shop might have better luck getting the finishes you need to match the HVAC exactly as opposed to a regular automotive paint shop - http://stickynomore.com (I just remember someone mentioning them on the forum, I have no personal experience). 3d printing could be a rather convenient way to make the DIN mount as well now that I think about it (the radio had screw mounts on the top and bottom of the unit didn't it?). Depending on what's going on and how involved things are getting I may be willing to CAD up that trim insert for you, I just can't commit to anything that's going to be too time intensive.

I'm not quite sure what you're planning with the plastic sheet and bonding but if I were you I wouldn't bond anything to the trim panel. Ideally you'd replicate the OEM setup where the gauges and the black pieces are mounted to the head unit DIN mounting holes and the trim sits over the part like it does with the radio. If you do that you'll be able to remove the trim a little easier without it being tethered down so much (I thought you mentioned wanting to do this earlier). Aesthetically I don't suppose it makes a difference if you can hold your tolerances (which would be easier to do with the gauges mounted to the trim panel if you're not comfortable with the model making stuff).

As far as making the trim panel itself I think you could get a bit more DIY if you cut the radio section out yourself of the OEM panel, 3d printed/machined (more expensive but more durable) an insert with the cutouts you needed and then bonded the two together. you could install the cut trim panel over the installed gauges with their DIN mount, then place the silver trim insert over them and align it properly, then jig the two parts together to make sure the holes are aligned properly, then remove and bond it all together. Depending on how comfortable you feel with the model making stuff it could be quite reasonable for you to get that silver trim panel together on your own in an unpainted state and then just hand it off to a paint shop to get the last bit of finish needed. This shop might have better luck getting the finishes you need to match the HVAC exactly as opposed to a regular automotive paint shop - http://stickynomore.com (I just remember someone mentioning them on the forum, I have no personal experience). 3d printing could be a rather convenient way to make the DIN mount as well now that I think about it (the radio had screw mounts on the top and bottom of the unit didn't it?). Depending on what's going on and how involved things are getting I may be willing to CAD up that trim insert for you, I just can't commit to anything that's going to be too time intensive.

Last edited:

- Joined

- 10 August 2010

- Messages

- 633

Josh, I've already talked about why it matters not that warning gauges be line of sight a bunch of times. I don't want to start sounding like a parrot. These gauges give PROPER warning, something few gauges do IMO, and line of sight simply does not matter because they are all distraction. Only one gauge matters to me on the track, my tach. I don't want to be watching other stuff and if I do want to see something, a clear legible analog gauge is much preferable to a multi-gauge. The functions some suggest I should have line of sight are actually things that should be data logged. I have both Data Logging and peak hold functionality.

What other gauge tells you by color and flash, showing only ONE function, hey things are good... hey things are getting a bit high.... and hey I am flashing at you and buzzing need your immediate attention. There is low warning, low, mid, high, and high warning on a legible analog DEDICATED gauge with peak hold and Data logging. Even triggers on warnings. That is EIGHT different ways of giving you information with a hierarchy built into each gauge and nothing else does that.

I don't have an AEM so that piece you are recommending isn't going to do anything for me. I've used plenty of gauges, and have done days of research and given this weeks of thought. I bet I know more about gauges right now than anyone on this board. I can tell you the ins and outs and good points and weaknesses of EVERY setup.

Your argument of it being dysfunctional isn't something I agree with. Everyone wants a certain look in their car, I am fine with a gauge cluster where my radio was. I much prefer that to the navpod and pillarpod.

Although I appreciate your input, I think we might be beating a dead horse at this point. I truly believe that I have the best setup for my needs. This thread is more aimed at getting these mounted well.

The AEM failsafe is one of the only gauges that has a warning system that works as it should. Most warnings need to be mapped vs other sensors. Wideband vs boost, oil pressure vs rpm, fuel pressure vs manifold pressure, etc.

A little late to this party unfortunately but I do have another solution on the way that will work with my app that does not require AEM EMS. I don't have all the details on this yet, I just got my hardware setup for it today, not even far enough along to release much information about it. It will read up to 16 5volt sensors directly. Simply buy the sensors a la carte and wire them up to the transmitter. Each sensor will serve the same purpose as a channel output from the AEM EMS as far as the software is concerned. This means you can map any sensors against one or more other channels for the warning system, datalog, etc. Both transmitters support triggers as well.

The AEM failsafe is one of the only gauges that has a warning system that works as it should. Most warnings need to be mapped vs other sensors. Wideband vs boost, oil pressure vs rpm, fuel pressure vs manifold pressure, etc.

A little late to this party unfortunately but I do have another solution on the way that will work with my app that does not require AEM EMS. I don't have all the details on this yet, I just got my hardware setup for it today, not even far enough along to release much information about it. It will read up to 16 5volt sensors directly. Simply buy the sensors a la carte and wire them up to the transmitter. Each sensor will serve the same purpose as a channel output from the AEM EMS as far as the software is concerned. This means you can map any sensors against one or more other channels for the warning system, datalog, etc. Both transmitters support triggers as well.

That sounds excellent. And I can still use it because each of my gauges has a 5V out. So no need to use two sensors.

- - - Updated - - -

KY650, you might have misunderstood me. The console is most definitely going to remain the trim piece I have no plans on mounting gauges to it. The gauges I planned on mounting via the double din mounting points onto a piece of finished ABS. The ABS sheets I bought are to serve for that double din pod as well as to replace a section of the console for the gauge trim.

No need for you to work for free, I am willing to pay for your time/help.

Sorry its been a while turbo. Here's a quick mockup of what you were talking about with a few more HVAC details (I just eyeballed them from your photos so they're definitely not very accurate). The dimensions were updated with the new ones you gave me as well. Keep in mind the way the gauges will look will change dramatically based on the angle of the lighting and all of that - in this render the light happens to be reflecting off their glass making them appear lighter than they would at other angles (where they'd be mostly just silver rings).

Last edited:

Thanks KY, that's exactly what I was envisioning. Can I fit a third row in there? I just received my machine grade ABS. What's your thoughts on any changes? I can make the ovals the same size and keep spacing on those two rows between the gauges the same, or space them like you have. I can also leave the bezels black, or even have just the glass show.

This is a public forum so I can comment right?

The uneven gap between the gauges on the top row vs the gauges on the bottom really bother me. I don't know why! lol

Similar threads

- Replies

- 12

- Views

- 699