Very nice, whats the compression ratio?

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3.6L ScienceofSpeed Engine (NA Stroker)

- Thread starter Ponyboy

- Start date

Based on all the questions we've received from this thread and prior stroked motors being built, we've put the most frequently asked questions and our replies on this thread.

http://www.scienceofspeed.com/sos_resource/FAQs/NSX/enpp/stroker_engines

If you have any questions, please let us know.

Cheers,

-- Chris

http://www.scienceofspeed.com/sos_resource/FAQs/NSX/enpp/stroker_engines

If you have any questions, please let us know.

Cheers,

-- Chris

Very nice, whats the compression ratio?

11.2:1. Fairly conservative.

Nice FAQ on the Stroker option, Chris. It frames the discussion nicely.

Last edited:

Up and running again...after a very long time. 3.6L v2:

The biggest difference is a change to Wiseco pistons. Dyno numbers are forthcoming sometime this week. Though it's been a while, I want to thank Chris, Jeff, and the rest of the guys at ScienceofSpeed for their professionalism, integrity, and for dealing with my semi-consistent nagging. Maybe I can get them to post a vid of what it sounds like...

Once I get it back, I'll be chronicling the builds, v1 and v2, in an upcoming issue of NSXDriver. And yes, I know I need a polished alternator.:wink:

The biggest difference is a change to Wiseco pistons. Dyno numbers are forthcoming sometime this week. Though it's been a while, I want to thank Chris, Jeff, and the rest of the guys at ScienceofSpeed for their professionalism, integrity, and for dealing with my semi-consistent nagging. Maybe I can get them to post a vid of what it sounds like...

Once I get it back, I'll be chronicling the builds, v1 and v2, in an upcoming issue of NSXDriver. And yes, I know I need a polished alternator.:wink:

Up and running again...after a very long time. 3.6L v2:

The biggest difference is a change to Wiseco pistons. Dyno numbers are forthcoming sometime this week. Though it's been a while, I want to thank Chris, Jeff, and the rest of the guys at ScienceofSpeed for their professionalism, integrity, and for dealing with my semi-consistent nagging. Maybe I can get them to post a vid of what it sounds like...

Once I get it back, I'll be chronicling the builds, v1 and v2, in an upcoming issue of NSXDriver. And yes, I know I need a polished alternator.:wink:

It's about time Sean :biggrin:...very curious on the numbers.

100whp because the dull alternator was robbing too much power! :tongue:

Congrats on getting the car back! The engine looks sweet.

Thanks Dave - haven't gotten it back yet but it should be soon.

Found out that the engine is making the same rwhp (333) but rwtq is up 9ft lbs to 275 now. The area under the curve is supposed to be better as well but I haven't seen the actual dyno yet. SOS said they'd take some video for posterity as well.

Found out that the engine is making the same rwhp (333) but rwtq is up 9ft lbs to 275 now. The area under the curve is supposed to be better as well but I haven't seen the actual dyno yet. SOS said they'd take some video for posterity as well.

- Joined

- 27 June 2003

- Messages

- 4,618

Up and running again...after a very long time. 3.6L v2:

The biggest difference is a change to Wiseco pistons. Dyno numbers are forthcoming sometime this week. Though it's been a while, I want to thank Chris, Jeff, and the rest of the guys at ScienceofSpeed for their professionalism, integrity, and for dealing with my semi-consistent nagging. Maybe I can get them to post a vid of what it sounds like...

Once I get it back, I'll be chronicling the builds, v1 and v2, in an upcoming issue of NSXDriver. And yes, I know I need a polished alternator.:wink:

don't forget the CF or polished aluminum alternator belt cover

Nice work... I want to do the 3.8L so baaaaaaad!

theres not time to wait for sos, send me a plane ticket and ill take some pics and make some vids:biggrin:

That's a beautiful torque curve! Did you choose to use 7500 rpm as the redline yourself for safety reasons or did SoS recommend that with their 88 mm crankshaft?

theres not time to wait for sos, send me a plane ticket and ill take some pics and make some vids:biggrin:

Haha...those would be some expensive pics & vids.

That's a beautiful torque curve! Did you choose to use 7500 rpm as the redline yourself for safety reasons or did SoS recommend that with their 88 mm crankshaft?

I know! W/ the 3.0, I had the same amount of torque that I now have at 1500rpm. The 7500 redline and power leveling off is more a function of the engine not getting enough air than any particular safety reason. Once we introduce less restrictive induction and let the engine really breath, the numbers should be even better and the 8krpm restored. Don't think I'll want any higher than that though.

So after reading one of our old posts I understand how the original engine went by by, then you had it rebuilt to a 3.6L and now it is rebuilt again (V2)? What happened or did I miss something? Why is it rebuilt again? Was the original cause of the oil starvation ever discovered?

I applogize if thes questions were asked and answered before.

Thanks,

Tytus

BTW congrats on your new engine build.

I applogize if thes questions were asked and answered before.

Thanks,

Tytus

BTW congrats on your new engine build.

Wow, your engine is trying to inhale a lot of air. Where do you think the restriction is? What kind of valves, cams, manifold, etc. are you using now?

Congrats on the news. It's been a long time coming. If I'm in the area, I definintely want a ride to see how the engine upgrades improve the NSX experience.

Cheers to you!

Shaun

Cheers to you!

Shaun

What happened or did I miss something? Why is it rebuilt again? Was the original cause of the oil starvation ever discovered?

No problem at all in answering your questions. v1 was rebuilt b/c it busted on the way back home to Tulsa. That bust was attributed to either a bad crank or some bad cylinder work (outsourced to a third party). From then until now, it's been at SoS.

The original cause of the oil starvation was a turn at Hallett called "The Bitch." My gallery has the bits and pieces of it's destruction including a pic of precisely when it happened. I can still remember the sound of it's demise...not pretty.

greenberet said:Wow, your engine is trying to inhale a lot of air. Where do you think the restriction is? What kind of valves, cams, manifold, etc. are you using now?

The intake manifold is the biggest restriction. Question is whether to go to a single large plenum (ie Hogans) or ITBs. I like the ITBs but need to figure out some sort of side induction and filtration system.

Build sheet is here but the 3.6-3.8L SoS engines all use SoS spec'd valves, cams, etc. The manifold is the stock unit with the bridge and material removed.

Shaun Ray said:Congrats on the news. It's been a long time coming. If I'm in the area, I definintely want a ride to see how the engine upgrades improve the NSX experience.

Well, as soon as it comes back, I'm getting it detailed (Tory volunteered

And I hear even some of the turbo guys that have driven in it have been impressed...:biggrin:

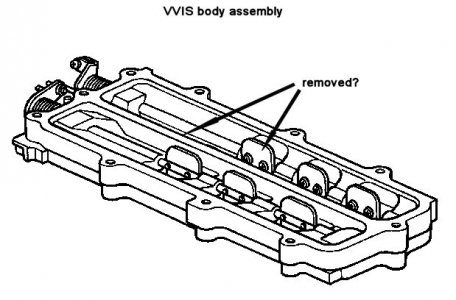

The manifold is the stock unit with the bridge and material removed.

So you've removed the VVIS butterflies and opened up the walls in the manifold, leaving only the short runners?

I would have thought that getting rid of the VVIS would do away with any restriction at high flow rates. Maybe VVIS is designed well and ditching it doesn't add many top-end hp. Or maybe you would have had even more of a restriction with the VVIS in place.

That's a beautiful torque curve! Did you choose to use 7500 rpm as the redline yourself for safety reasons or did SoS recommend that with their 88 mm crankshaft?

What curve? That thing is flat as a pancake!

I would have thought that getting rid of the VVIS would do away with any restriction at high flow rates. Maybe VVIS is designed well and ditching it doesn't add many top-end hp. Or maybe you would have had even more of a restriction with the VVIS in place.

VVIS was designed for the stock engine and not one that is as highly modified. That said, I think they're may be some very minimal losses at low RPM (1500 to 3k?) but is more than offset by the gains at higher RPM. If I'm at 1500 to 3k at the track...something more is wrong than that minimal loss.

Chris put together a good FAQ on the stroker engines here if you're interested.

Thanks for the link to the FAQ. In it, Chris states, "In addition, the heads, cams, and other components are reworked specific to the application."

Just to be sure, in your specific application, has the VVIS system been gutted, the butterflies removed, and the internal walls ground away so that only the outer walls of the housing remain? Also, has the central wall in your intake mainfold been ground away?

Just to be sure, in your specific application, has the VVIS system been gutted, the butterflies removed, and the internal walls ground away so that only the outer walls of the housing remain? Also, has the central wall in your intake mainfold been ground away?

Attachments

Off hand, I'd say yes. The VVIS and bridge removal was part of SoS's NA Tune 1 (or something to that effect) and my intake manifold rec'd that treatment years ago. But maybe SoS had some more things done w/i the intake manifold (though I can't imagine what else could be done) to achieve the result above.

Let me get back to you so I can give a definitive (or as close to it as possible) answer...:wink:

Let me get back to you so I can give a definitive (or as close to it as possible) answer...:wink:

Last edited:

No problem at all in answering your questions. v1 was rebuilt b/c it busted on the way back home to Tulsa. That bust was attributed to either a bad crank or some bad cylinder work (outsourced to a third party). From then until now, it's been at SoS.

The original cause of the oil starvation was a turn at Hallett called "The Bitch." My gallery has the bits and pieces of it's destruction including a pic of precisely when it happened. I can still remember the sound of it's demise...not pretty.

<snip>

Hallett did not damage your engine. The Bitch is not even a carousel.

You may want to find out what really caused the problem.

Also, in my car, I experienced an "engine cut out" a few times, and I assumed it was due to TCS engaging. It was in a right-left S turn at the top of 3rd gear on a flat track. After thinking about it more, I checked my oil level. It was just a touch below the bottom of the "add" line. So, I added a quart and it didn't do it again.

The point is that - even if there is temporary oil starvation, the engine will cut itself out and not blow itself up.

For all you guys who think "certain turns" blow up your engines, you seem to not be considering all the evidince of 17 years of NSXes being on tracks all around the country.

Remember NSXPO in Ohio (#2)? We did the skid pad. That is max G turn, sustained. Both directions. Not a single engine failure.

I hope you consider looking for the real cause and I am envious of a stroker motor.

Good luck.

Hallett did not damage your engine. The Bitch is not even a carousel. You may want to find out what really caused the problem.

The "Bitch" is a high G corner. No where at Hallett do you pull more or do you change in more elevation.

FWIW, the engine busted from a spun con rod bearing which was attributed to oil starvation. The NSXs oil starvation issue is fairly well known among the engine builders I've spoken to. I don't really feel the need to justify any further or get into a potential argument.

Thanks for the well wishing though.

Last edited:

Similar threads

- Replies

- 9

- Views

- 430

- Locked

- Replies

- 4

- Views

- 409