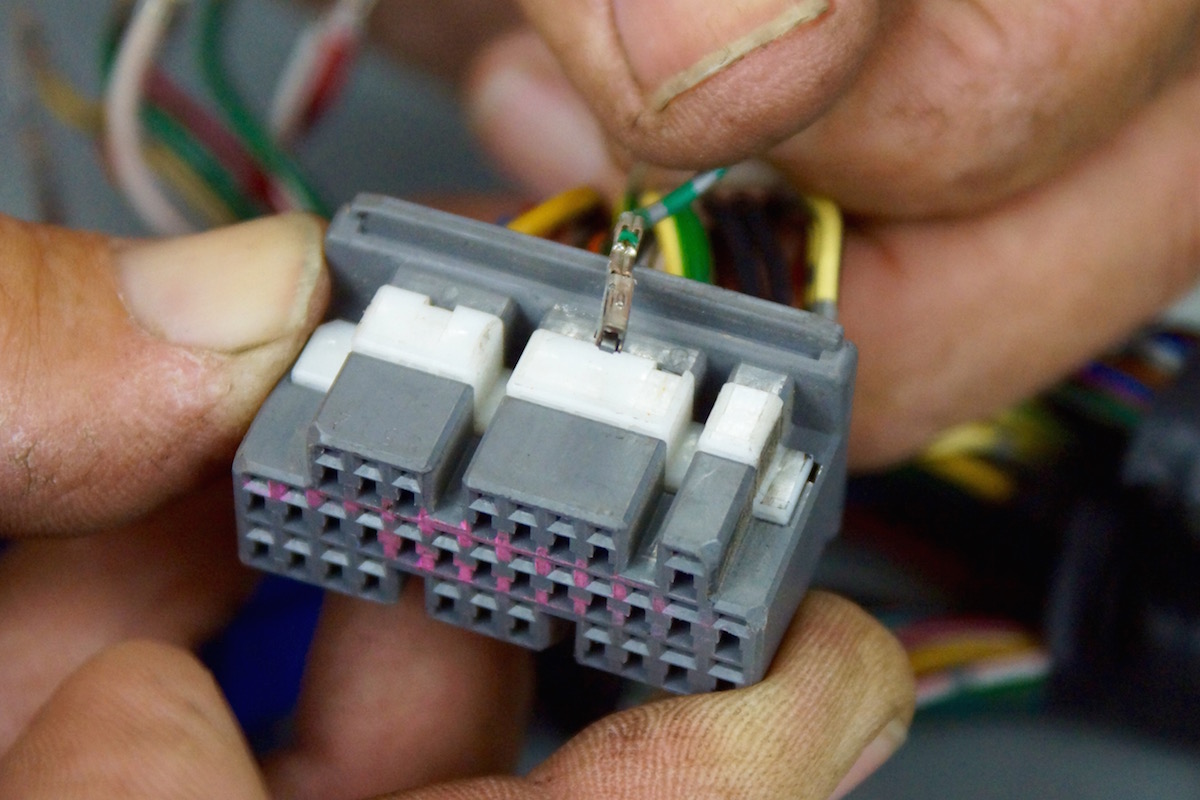

I’ve been tracking down the cause of some weird behavior and managed to isolate it to a potential bad connection on a couple wires at the ECU. My car had a bunch of t-taps on wires at the ECU when I bought it. You can see some of the little cuts on the wires here. At least one of these is causing intermittent issues

I’m looking to repair all these and curious if anyone has any really clean approaches to repairing these. I’d love to not cut them, just strip a little insulation, put some crimp on them and shrink wrap. But I can’t find anything nice to crimp without cutting the wires. Any butt connectors small enough (probably) don’t fit over the ecu pins.

Seems like I have a couple options

* strip some insulation, solder, shrink tube

* cut them at the damage, crimp with some really small butt connectors (I have some 24-20awg connectors coming), shrink tube. Leaning this way

Anyone have a super nice way to fix these?

I’m looking to repair all these and curious if anyone has any really clean approaches to repairing these. I’d love to not cut them, just strip a little insulation, put some crimp on them and shrink wrap. But I can’t find anything nice to crimp without cutting the wires. Any butt connectors small enough (probably) don’t fit over the ecu pins.

Seems like I have a couple options

* strip some insulation, solder, shrink tube

* cut them at the damage, crimp with some really small butt connectors (I have some 24-20awg connectors coming), shrink tube. Leaning this way

Anyone have a super nice way to fix these?