Voltage drop rabbit hole

Waay back in September I installed

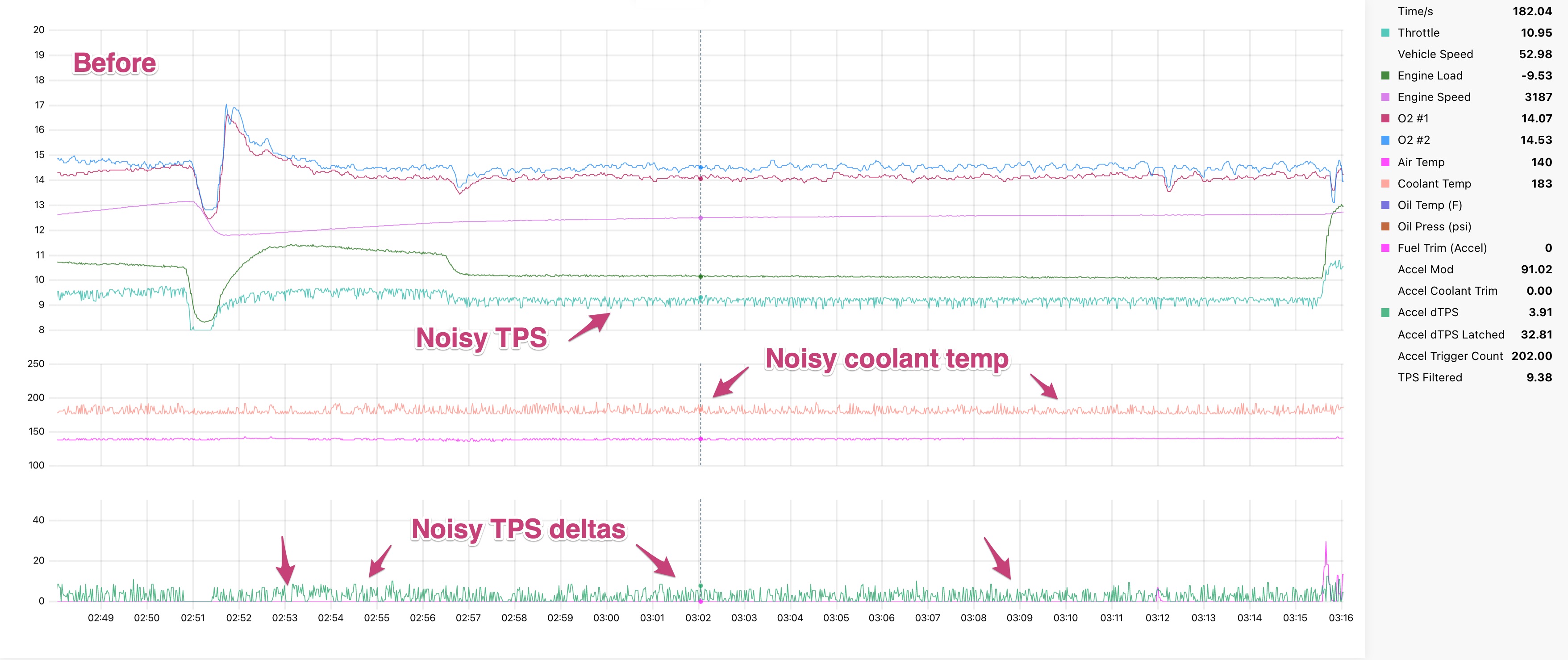

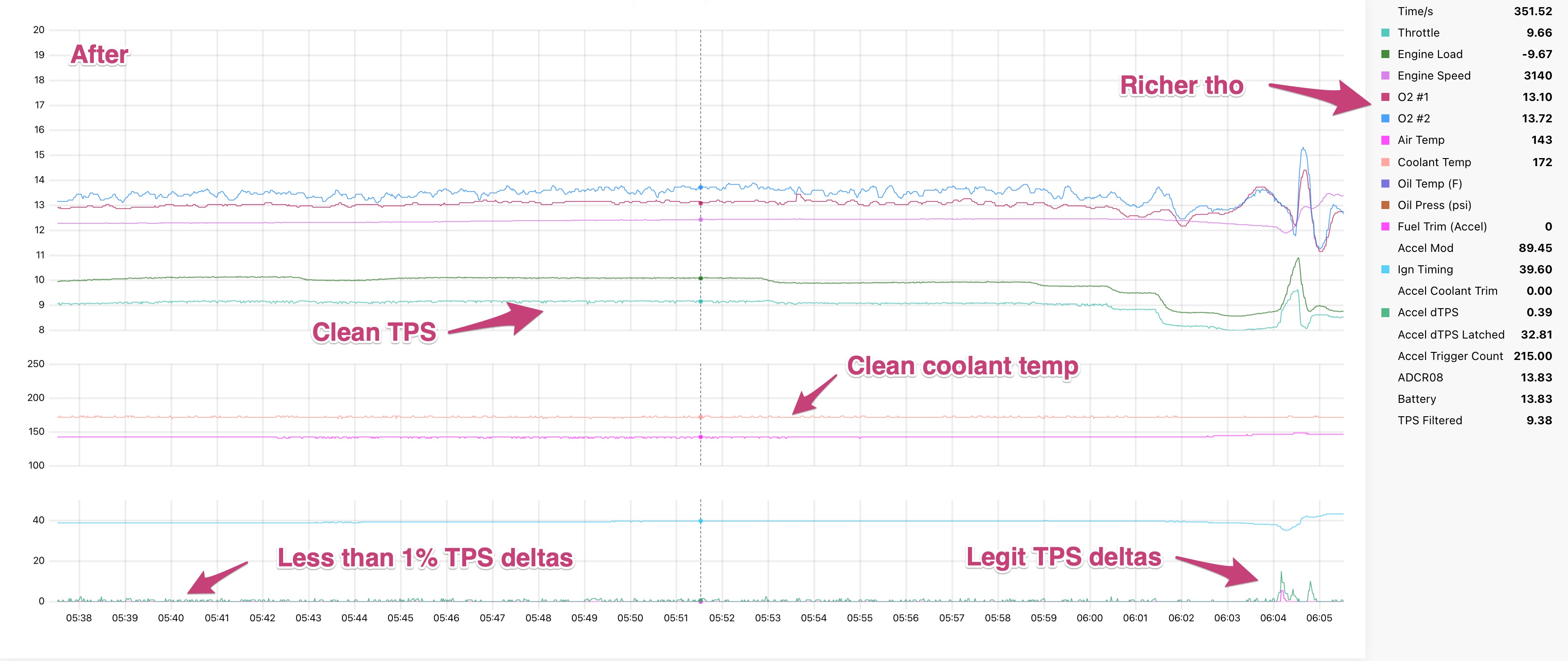

k-series coils to replace the stockers. Setting coil dwell in the ECU was not straightforward and required a lot of trial & error: do some logging, change some settings. The coil dwell tables are based on ECU voltage, so I logged the internal ECU voltage just to see the behavior. Logging voltage was kind of theater, curiosity; I expected it to be pretty consistent somewhere around 14v.

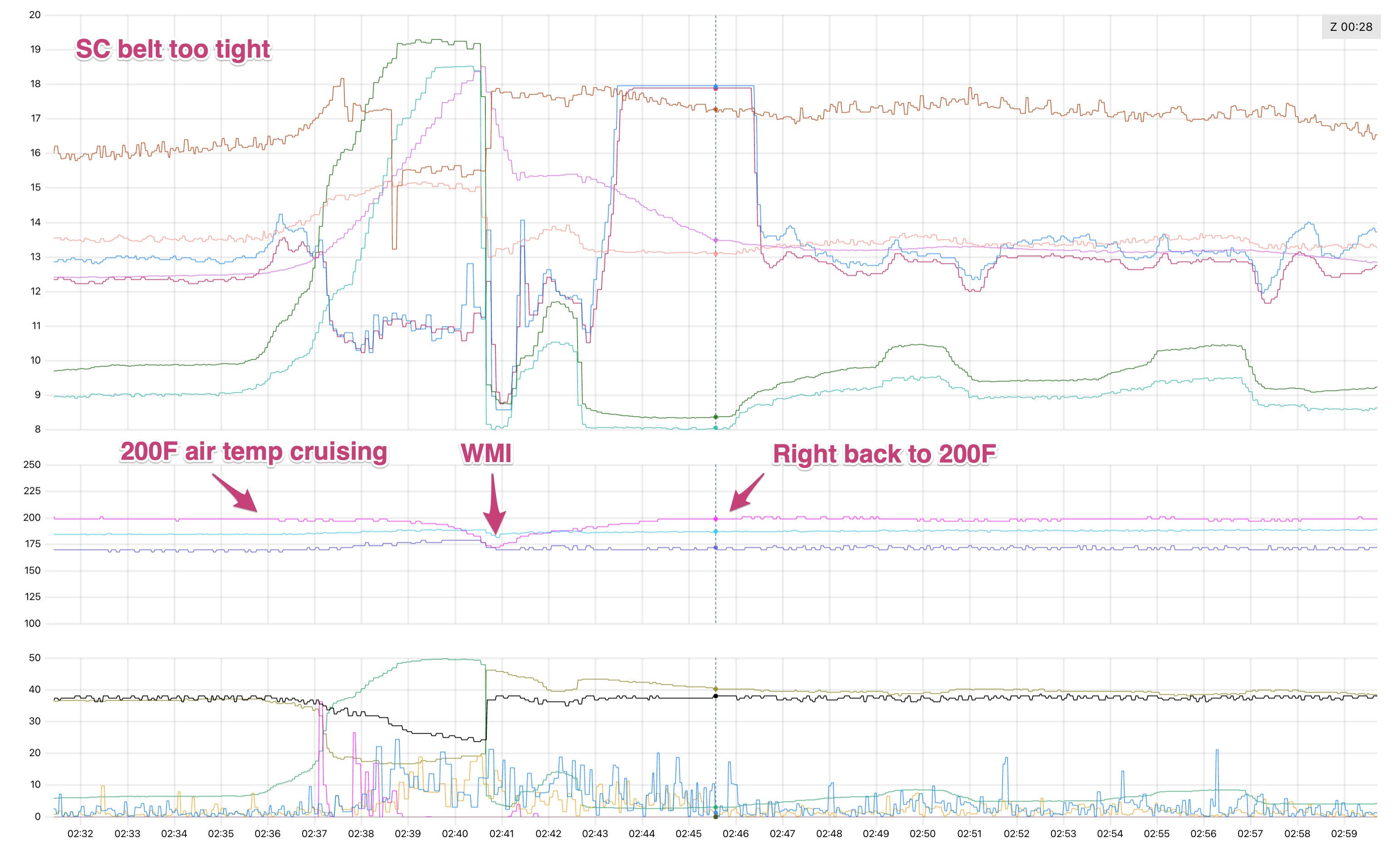

But it wasn't consistently 14v. The logs showed that it hovered around 13.8v (gauge in the car said 14.2v) while cruising and had a pretty significant voltage drop in boost. It'd get down to ~12.5v, check it out:

Annoying. Nothing was really wrong, but maybe it was indicative of something larger? In any case, it felt wrong and I figured I could fix it.

I

posted a thread asking for help, so you can see the whole discovery process there. But I'll summarize in this post.

This was a 6 week wild goose chase and I'm back to where I started, except now I don't feel comfortable driving the car for reasons I'll get into later. It'll be fine once I fix some stuff, but it's a garage queen for the next couple months. Derp.

What is problem?

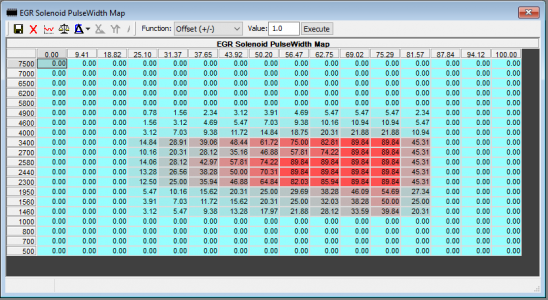

I thought the voltage drop was probably caused by the alternator. Because of the CTSC, the car uses a 92 prelude alternator which is only 90A. My hypothesis was that the WMI, fuel pump, and maybe coils had huge current draw at high RPM, but the alternator couldn't keep up. Or there was alternator belt slip.

I should have done more tests before coming to that conclusion, buuuut I didn't. No downsides, I thought. A high output alternator could only be better, right? Might as well just buy one and see....

HO alternator

I needed a 92 prelude alternator. The 92-96 prelude isn't a popular tuner car, so these things were pretty hard to find. The car audio world has a lot of experience with upgraded alternators, and those guys trust only 2 or 3 alternator brands. The most promising for me were Mechman and Singer. Mechman never got back to me, but the Singer guy did.

Singer was convinced that the 97+ prelude alternator was the same form factor as the 92-96. He's the expert, right? He built one and sent it. Welll, the 97+ alternator was totally different in every way, 6 rib, smaller pulley, much larger case, mounting points didn't line up, different plug, etc. He tried to convince me to modify it to fit, but no thanks.

I sent it back and he built one with a 92 prelude case. Because it is smaller, I guess there are some limitations on how it can be modified. I dunno, but here it is:

One immediate downside was that it came with a smaller pulley:

Maybe it was fine though. I got a smaller belt and installed it:

Did the new alternator fix it?

Did the new alternator fix it?

No. In fact, several other things were worse. Immediately on startup it was super noisy, like a bad bearing howl. Okay, but maybe the voltage drop was better?

Also no. With the belt pretty tight (no boost fade) and under load, the battery light would come on and the voltage drop was still there. Not ideal. I tightened the belt more, but still battery light flicker in boost.

I figured the pulley was too small. Either it doesn't have enough leverage at a reasonable belt tension, or it's spinning too fast. Apparently the RPM limit for an alternator is like 16-18k RPM, after that they stop charging. I did some math and with the small pulley, it'd be 20k+ at 8k engine RPM. With the stock pulley it'd be under 16k RPM at 8k engine RPM.

I put the larger stock pulley on the HO alternator, and tried again. Battery light gone, but the voltage drop in boost was still there, behavior looked exactly the same. Dumb.

Even though there was no more battery light, there were more problems with the HO alt + larger pulley. It wouldn't hold voltage at idle, and it couldn't deal at all with any accessories. 12.5v at idle here (12.8v at the gauge):

Allllso, on RPM changes, there were voltage spikes not present with the denso alt. It was more pronounced at idle, but still would spike to ~15v on the gauge while cruising and stabbing the throttle. Here it is at idle. This log says the spike is 14.6v, but through this process, I learned that the ECU consistently reads 0.3v lower than the gauges, so this is just under 15v, and I definitely saw > 15v on the gauge:

Ultimately I went back to the stock prelude alternator. With the HO alt, I'd need to deal with either a battery light or no voltage at idle. Plus it had consistent bearing noise at idle and electric whine at 3k+, and ran waaay hotter than the denso alt. All no bueno, and the drop issue wasn't fixed anyway.

Testing

Throughout

my diagnosis thread, Old Guy was crazy helpful in trying to track this down. The goal of the testing was to figure out exactly where the drop was. Was it in the ECU? The whole car? The ECU / injector circuit? This is the work I should have done in the first place, instead of buying the alternator.

I added a CAN bus expansion module which also output voltage. The module is run off the ECU power pins, so exact same circuit/voltage the ECU is getting

Installing this was its own saga. The AEM docs had the addresses wrong for some of the CAN messages, so it took a lot of trial and error to get the right data. But it worked, here it is in the navpod (bottom right):

I took it out with the gopro pointed at the dash and 4 (5?) different volt meters:

1. A voltage gauge on the IGN circuit (round gauge)

2. A battery meter on the battery terminals (on the phone)

3. ECU logged voltage (navpod right, 2nd from bottom)

4. New CAN voltage (navpod right, bottom)

5. Battery light

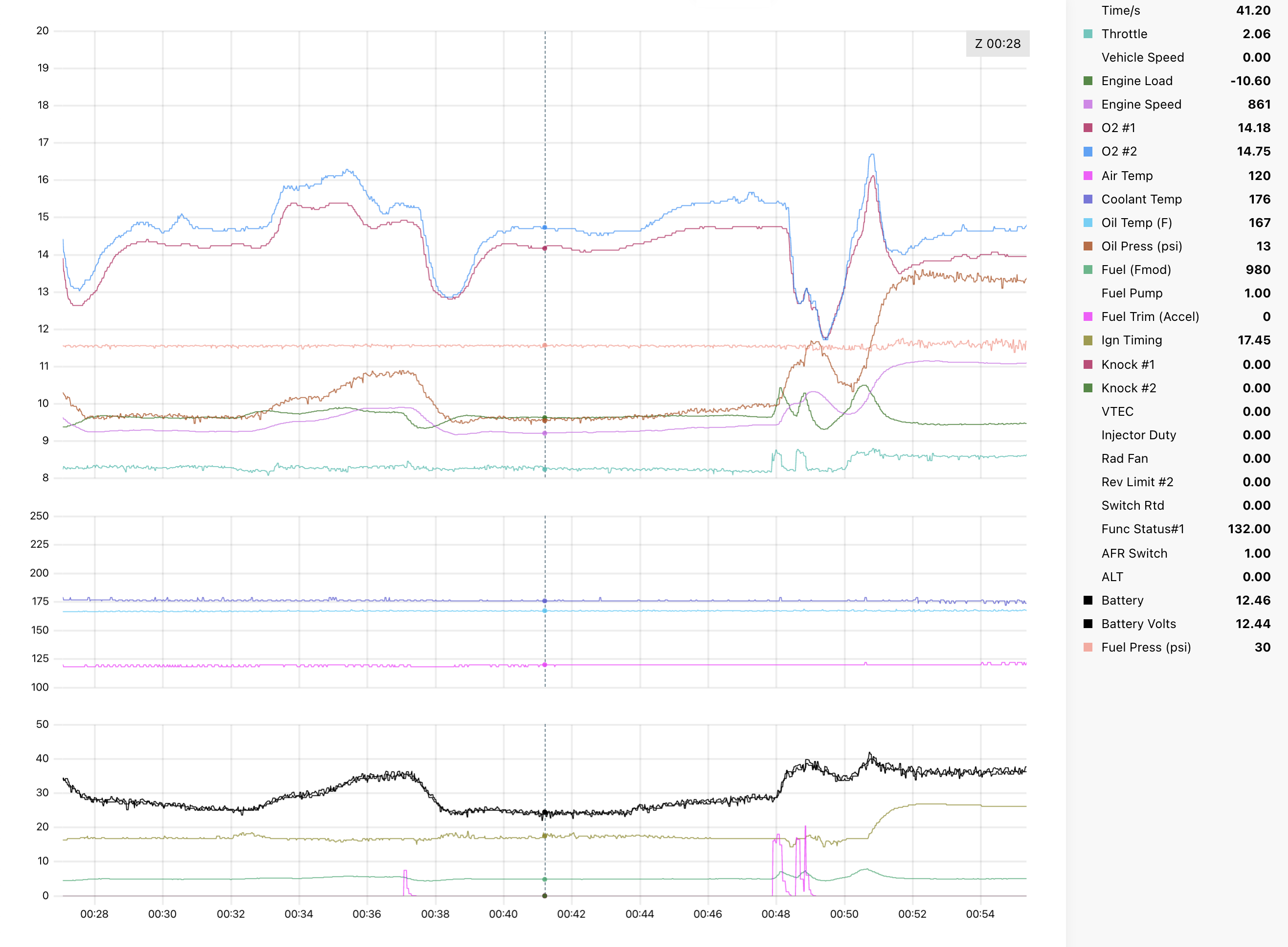

At idle, they all pretty much agree, except for the ECU-reported volts, which is always ~0.3v lower. Then during a pull it showed this:

What does it all mean?! The conclusion was that things are probably fine.

The pic indicates that the drop is in the ECU voltage circuit, which is the same circuit driving the injectors. At high RPM in boost at 40-50% injector duty cycle, there are probably 3 injectors (8 - 9 ohms, 1 - 1.5A each) open at once which causes a voltage drop in that circuit. The voltage drop only really affects the opening of those injectors, which is compensated in the ECU.

That was kind of The End. Whomp whomp. Several weeks of trying stuff and installing the alternator 10 times with no real resolution.

I guess the drop is fine and maybe even normal. Old Guy thought maybe there was similar behavior in a stock car as well.

I broke stuff

Other than some cleaner grounds and a new gauge in the navpod, I'm mostly back to where I started: on the denso prelude alternator, and still with a voltage drop.

During this whole process, one potential problem was belt slippage at the alternator. How do you solve that? A tighter belt? Belt tension on the SC / alt is known to be art: tighten until you can't twist the belt in a certain place past 90 degrees, then it's tight enough.

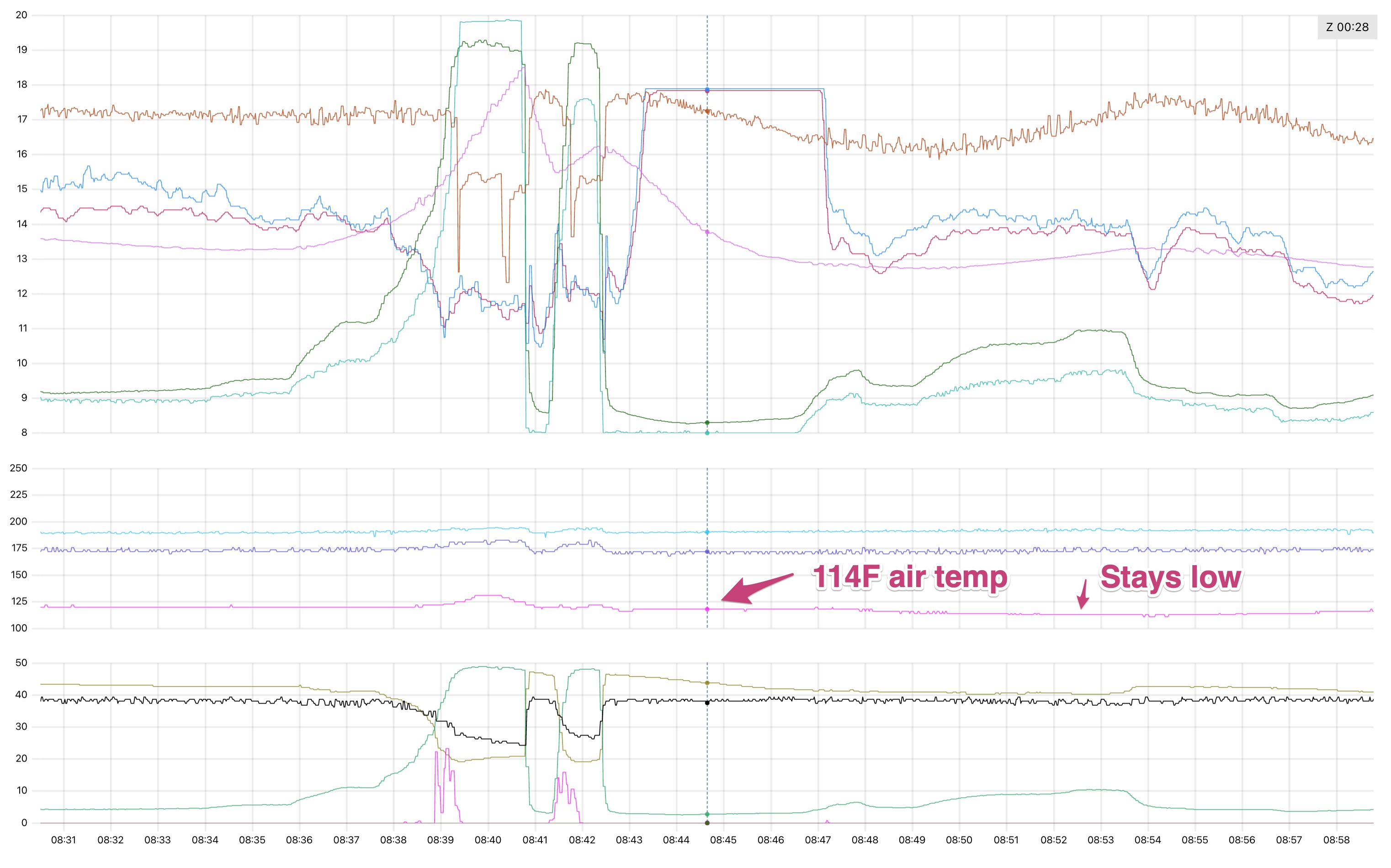

For a couple drives I had it pretty tight, but I could still twist it only 90 degrees. In one of these drives I noticed the air temps were super high, even when cruising.

Before tightening the belt, the air temps would usually be pretty low when cruising. During a pull, the WMI would kick in, then after, the air temps would settle lower than the pre-pull temps. These logs were taken in November where the ambient was ~60 degrees f, which usually gives ~110-120f cruising air temps. This is normal:

But with a super tight belt, air temps were HIGH, and they were high

all the time.

I've never seen air temps this high, and it seemed to coincide with RPM, even when cruising. At 3k rpm: 200f, pull up to a stop light, they'd drop to 180f. Not good.

Loosen the belt, and things go back to normal, right? Right?!

No, ugh. I have since loosened the belt significantly to where there is a lot of boost fade. The air temps are still really high, they creep up pretty quickly after a cold start, and still the same pattern. I used the temp gun on the SC after a few of these drives and the snout + gear case was HOT: 175-180f, same as air temps at idle.

SC needs a rebuild

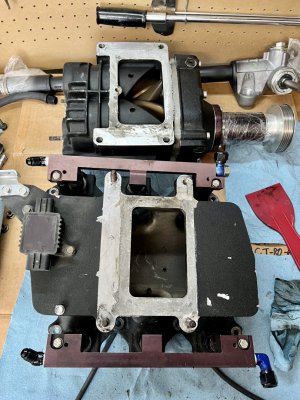

Well, I likely damaged something in the SC snout or gear case by overtightening the belt. I called Jon Bond performance (supercharger rebuild people) and asked about this, they said they see bearing damage causing heat from overtightening all the time. It's nothing catastrophic, but probably needs a rebuild. I have one scheduled with Jon Bond for early March.

The upside is that during the rebuild, they will also inspect everything else, replace all the bearings, ceramic coat the rotors, powdercoat the rotor case, and ceramic coat the snout. So it should be brand new when I get it back. The guy on the phone said people often see a noticeable efficiency increase after a rebuild because of the fresh rotor tolerances.

I also have a phenolic sandwich plate that goes under the blower, so I was planning on pulling the SC and intake manifold anyway. Fate, I guess.

I now have a belt tension gauge and a bunch of boost fade data at different tensions (both hot and cold tension). When I get the SC back from rebuild, I'll creep up on tension until there is minimal boost fade. I definitely don't want to mess this up again.