I ended up buying another core block from

@acuhon and starting over. I talked to several machinists and what it boiled down to was the old block was too far gone, and that the best use for it is as the basis for a stroker engine that uses larger cylinder bores and main bearings. I'm not sure if that will be my project or if someone else will get a screaming deal on a core block for a stroker that already has sleeves in it. With all these C30 parts I've got though, anything is possible.

Unfortunately, I don't really have any recourse for that old block, as I'm not sure if it was messed up before it ended up at the shop or if the machine shop screwed up the line hone operation. But either way, I will never send any work to Darton East/Howards Hotrods again, I waited over a year to have sleeves installed and I got back a very, very expensive paperweight. One of the bores was damaged when I got it back the first time, and then when I got it back the 2nd time a corner of the block was smashed in and the packaging was not damaged, meaning it happened in their shop.

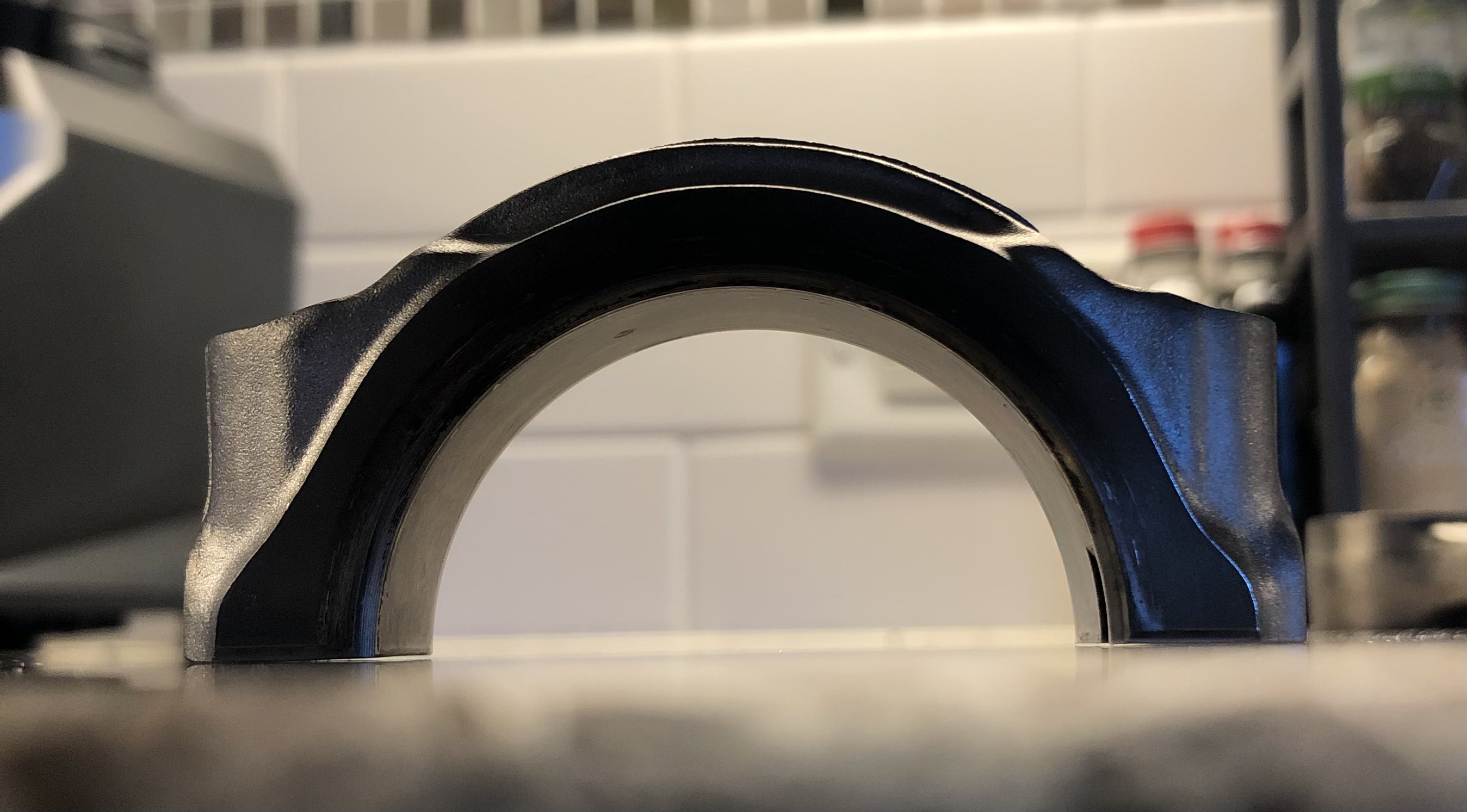

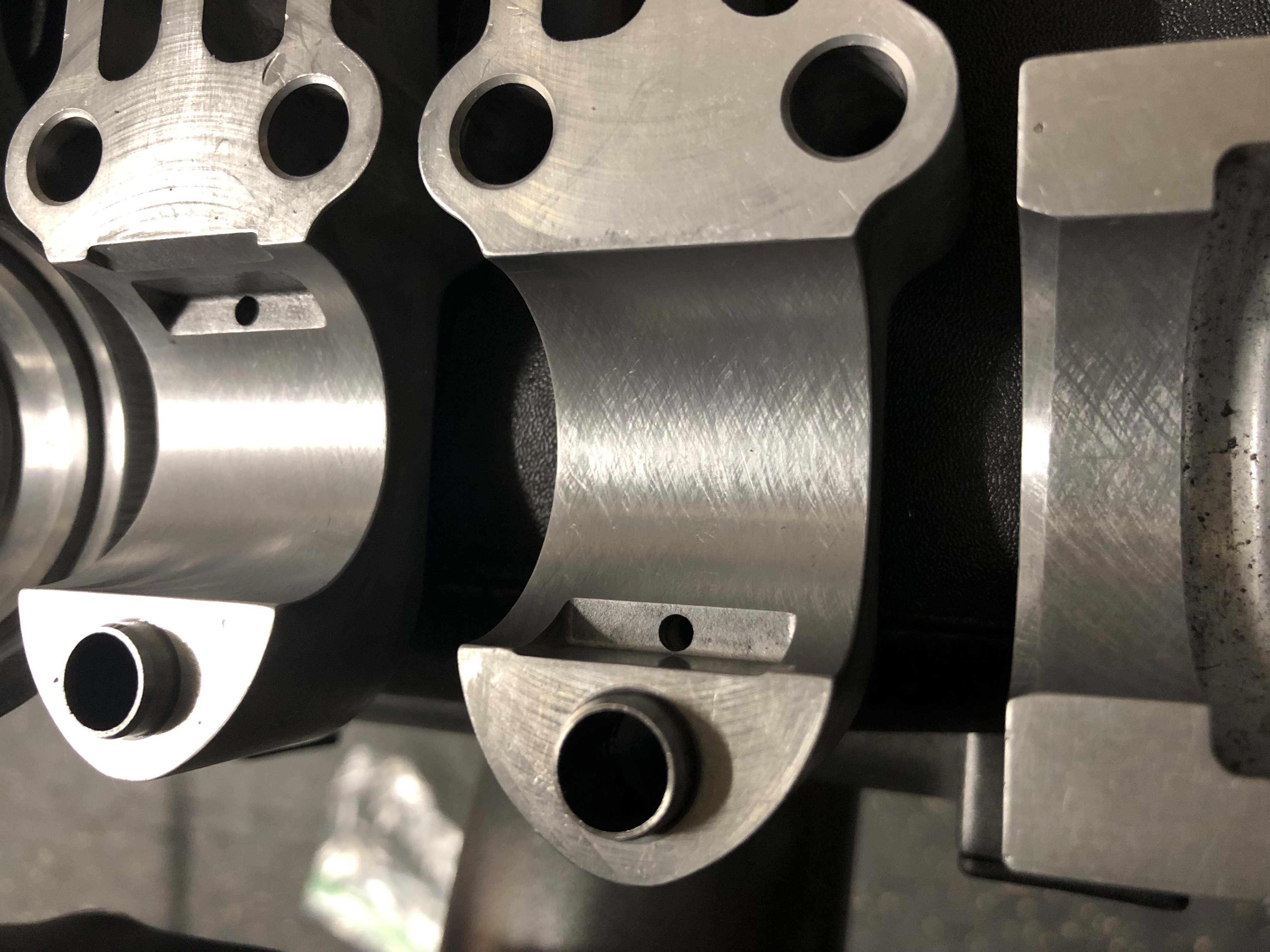

The new core is in MUCH better shape than the other one, the mains are all true to within 0.0005" which is great for used parts, the threads are all in good shape too. The other one had some stripped threads and poorly done thread repairs. Here it is in my back yard for cleaning, after that I shipped it to Mountune in California to have the main tunnel rebored with billet main caps, then from there its going to Benson for sleeves and final bore/hone.

I got the Endyn heads back from the machinist as well. The valves and seats were in great shape so he didn't do a full valve job, instead he touched up the 45 degree angle in the seats (maintains the angles used in the valve job by Endyn) and cut the valves and everything sealed up perfectly, then surfaced the heads on a proper fly cutter instead of the belt sander type surface job these heads had when I got them.

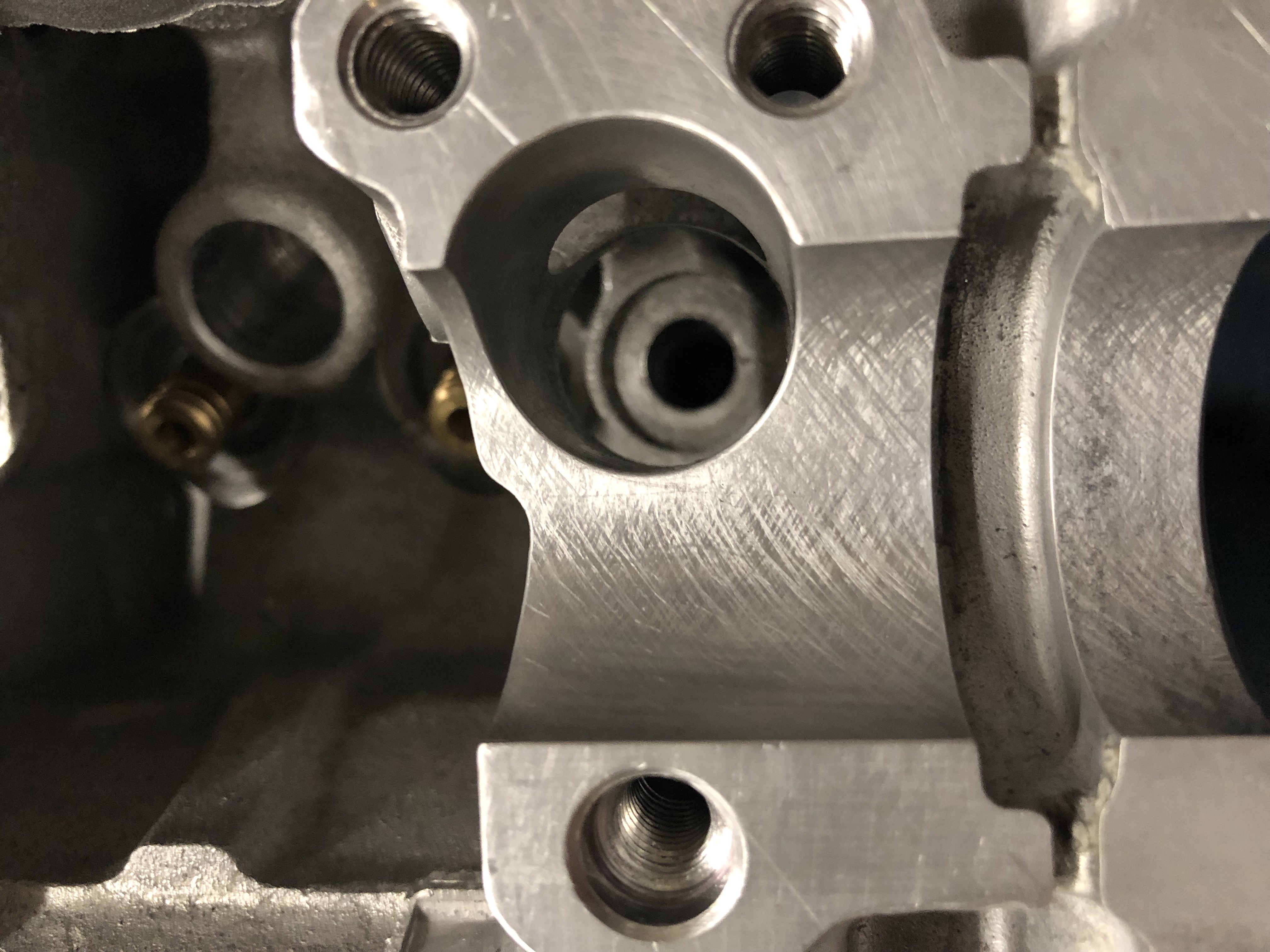

NSX heads (and other Hondas in general) tend to score up the cam caps and even wipe them out in the worst case, so I bolted the cam cap assemblies on and lightly honed the cam tunnels using an 800 grit flex hone (dingleberry hone) to add some light crosshatching to improve oil retention and make sure all of the edges are nicely deburred around the cams.

Oil clearances changed by maybe 0.0002" from before and after the honing process, showing that this is more of a surface finishing operation rather than really removing any material, 0.0030" is still at the low end of the new spec.

I also deburred all of the holes in the head surfaces. This is by no means required but those sharp edges tend to catch on whatever you use to wipe the heads down so this prevents that and makes clean assembly easier. Theres some small scuffs and what not on the head surface but those cannot even be felt with a fingernail, aluminum heads are very soft to the point that even cardboard will visibly mar them.

Finally, I got some extremely fine 1200 grit lapping compound and lightly lapped each valve into its seat. Again, this removes virtually no material and is essentially just polishing the valves into the seats so they seal perfectly and also lets me visually verify that the valves mate perfectly with the seats. Its just a minute or two per valve very lightly lapping by hand. The discoloration is just due to the inconel metal discoloring from heat, as these heads were previously ran. Once done, you can very clearly see the contact area between the valve and the seat.

I'm also trying to figure out the best way to open up the 3.0 chambers to fit a 3.2 bore which is 93mm instead of 90mm. The factory 3.2 chamber is basically just a 3.0 casting with a small amount machined out to fit the larger bore size at the top, as seen here (image courtesy of Cole Mulvey of Bad Guys Worldwide machine shop). The deshrouding cut around the intake valves is also a little bigger than the factory 3.0 casting due to the larger valves and the larger bore affords more room.

That's a rather crude way to do it though since it leave some sharp edges protruding into the chamber. So what I'd like to do is find someone who can use a deshrouding cutter to cut the area around the valves out to 93mm to give the valves the most room to flow then chamfer the rest of the chamber out to 93 to match. I'm not sure if that will be viable though so I might just knock the sharp edge down and run it as-is.

Anyways, I'm hoping the block will be back from Mountune within a few weeks so I can get the main clearances set up and send it along for sleeves, and finally get this thing together. Or maybe I'll get lucky and someone will break into my house and steal all my engine parts, and release me from this prison.