Engine Refresh 10

Finished the intake manifold. It felt nice to be moving to the phase where I start putting parts into the car rather than taking them out.

All gasket surfaces wiped with acetone to remove any trace of grease.

Magnesium bottom plate attached. All bolts torqued to the spec (22nm) in two stages (12;22) using my new Tonichi wrench. It's awesome!

EGR port cover with the new gasket.

Refreshed EACV with the new bolts.

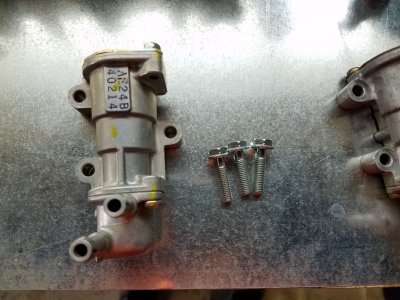

Brand new FITV fresh from Japan with the new bolts.

The FITV comes with O-rings pre-installed. I did not know this and ordered an extra set!

Detail of FITV with the new bolts

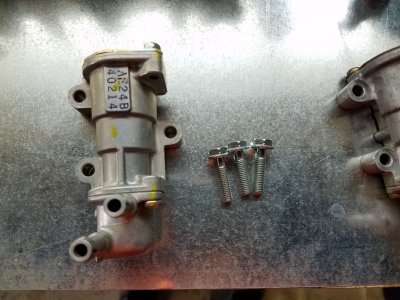

Old versus new. They changed the top screws since 1992.

New air temp sensor. As this NSX will require extensive tuning, I want to make sure the sensor inputs are accurate.

Assembled.

Really pleased with this refresh. This NSX is going to breathe like an olympic athelete!

Finished the intake manifold. It felt nice to be moving to the phase where I start putting parts into the car rather than taking them out.

All gasket surfaces wiped with acetone to remove any trace of grease.

Magnesium bottom plate attached. All bolts torqued to the spec (22nm) in two stages (12;22) using my new Tonichi wrench. It's awesome!

EGR port cover with the new gasket.

Refreshed EACV with the new bolts.

Brand new FITV fresh from Japan with the new bolts.

The FITV comes with O-rings pre-installed. I did not know this and ordered an extra set!

Detail of FITV with the new bolts

Old versus new. They changed the top screws since 1992.

New air temp sensor. As this NSX will require extensive tuning, I want to make sure the sensor inputs are accurate.

Assembled.

Really pleased with this refresh. This NSX is going to breathe like an olympic athelete!