Engine Testing 2

Thanks to the timely intervention of @Kaz-kzukNA1 we are making progress. In order to "re-clock" the thermostat to 12:00, I drained about a gallon of coolant from the rear engine block drain. This minimized spillage when we removed the thermo cover, which was nice. However, it also re-introduced a lot of air into the system. This time, we re-filled the coolant using the funnel and bleeder method like in the workshop manual.

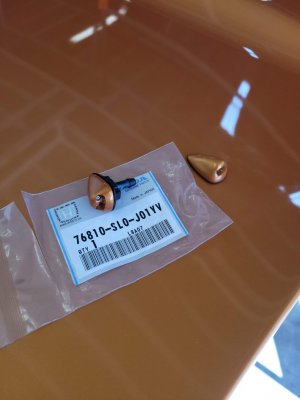

Upon removing the thermostat, I discovered that it had no float pin. Although this feature is not required on a thermostat for proper functioning, on a car like the NSX with its complex cooling system, having an air port helps. So, upon the suggestion of @Big McLargeHuge, I drilled a 1/16" hole in the top of the stat. This is an old hotrodders trick to help purge air from the system. While the tiny hole will allow a small amount of hot coolant to bypass the stat, it shouldn't really affect warmup time much at all and will greatly aid the air purging process. I installed the stat with a new gasket.

Although this feature is not required on a thermostat for proper functioning, on a car like the NSX with its complex cooling system, having an air port helps. So, upon the suggestion of @Big McLargeHuge, I drilled a 1/16" hole in the top of the stat. This is an old hotrodders trick to help purge air from the system. While the tiny hole will allow a small amount of hot coolant to bypass the stat, it shouldn't really affect warmup time much at all and will greatly aid the air purging process. I installed the stat with a new gasket.

Next was the Kaz air purge process.

We first ran the car for 60 seconds to move the air pockets.

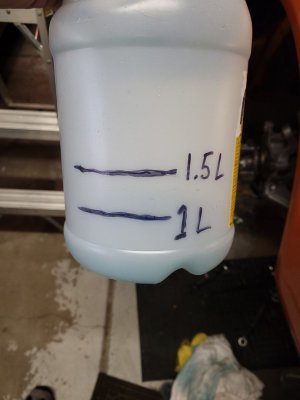

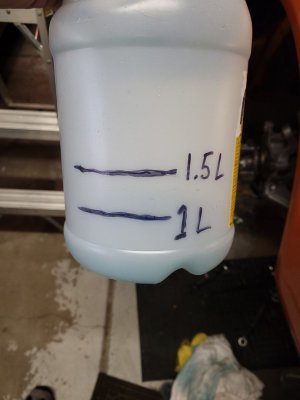

Armed with a jug marked off at 1L and 1.5L, we proceeded.

Filled the coolant tank to the neck (actually a little above)

A good amount of air came out of the thermo cover bleeder, but we soon had a steady stream. 1.5L collected.

Next up was the radiator, which let out a lot of air and then a steady "squirt" of coolant each time the plug was wiggled.

Then, the heater core, which funny enough had almost no air. It was pretty much a steady stream of 1.5L collected.

Next was the crazy part- the water pipe bleeder on the rear firewall. This thing was bubbling air out the entire 1.5L! Near the end, the stream got more solid, but it was MUCH more air than we expected.

One more time on the thermo cover (almost no air) and we were ready for the warmup. Here's where it got interesting. I connected the laptop to the ECU so we could monitor the temperature. As you can see in the video, the coolant temp was at 85C, but the thermo hose was still cold. Finally, at 93C, the coolant started to bubble out of the bottle cap and we shut it down.

Finally, at 93C, the coolant started to bubble out of the bottle cap and we shut it down.

The rad fan never kicked on.

View attachment 20221228_195542.mp4

It was clear that the thermostat did not open, even though it should at this temperature (it's an 80C stat). @Big McLargeHuge, on a whim, started squeezing the thermo hose and we could hear the water sloshing in the pipe, even under the car. Then, the strangest thing happened. While continuing to squeeze, Tyler said "Ow!" and pulled his hand away from the thermo hose. It had suddenly gone from lukewarm to scalding hot. Clearly, the thermostat had popped open, allowing the hot 90C coolant to flow into the thermo hose. The best we can guess is that the brand new stat was "sticky" with the dry metal plunger "stuck" to the dry metal housing. The agitation/pressure of Tyler squeezing the water dislodged it and it opened correctly. It also explains why the rad fan never kicked on, since the sensor is on the thermo cover side of the stat, the water was not warm enough to trip the fan.

I let the car cool overnight and will warm it up again today. Now that the thermostat plunger is free, I think I will have a better result!

Thanks to the timely intervention of @Kaz-kzukNA1 we are making progress. In order to "re-clock" the thermostat to 12:00, I drained about a gallon of coolant from the rear engine block drain. This minimized spillage when we removed the thermo cover, which was nice. However, it also re-introduced a lot of air into the system. This time, we re-filled the coolant using the funnel and bleeder method like in the workshop manual.

Upon removing the thermostat, I discovered that it had no float pin.

Next was the Kaz air purge process.

We first ran the car for 60 seconds to move the air pockets.

Armed with a jug marked off at 1L and 1.5L, we proceeded.

Filled the coolant tank to the neck (actually a little above)

A good amount of air came out of the thermo cover bleeder, but we soon had a steady stream. 1.5L collected.

Next up was the radiator, which let out a lot of air and then a steady "squirt" of coolant each time the plug was wiggled.

Then, the heater core, which funny enough had almost no air. It was pretty much a steady stream of 1.5L collected.

Next was the crazy part- the water pipe bleeder on the rear firewall. This thing was bubbling air out the entire 1.5L! Near the end, the stream got more solid, but it was MUCH more air than we expected.

One more time on the thermo cover (almost no air) and we were ready for the warmup. Here's where it got interesting. I connected the laptop to the ECU so we could monitor the temperature. As you can see in the video, the coolant temp was at 85C, but the thermo hose was still cold.

The rad fan never kicked on.

View attachment 20221228_195542.mp4

It was clear that the thermostat did not open, even though it should at this temperature (it's an 80C stat). @Big McLargeHuge, on a whim, started squeezing the thermo hose and we could hear the water sloshing in the pipe, even under the car. Then, the strangest thing happened. While continuing to squeeze, Tyler said "Ow!" and pulled his hand away from the thermo hose. It had suddenly gone from lukewarm to scalding hot. Clearly, the thermostat had popped open, allowing the hot 90C coolant to flow into the thermo hose. The best we can guess is that the brand new stat was "sticky" with the dry metal plunger "stuck" to the dry metal housing. The agitation/pressure of Tyler squeezing the water dislodged it and it opened correctly. It also explains why the rad fan never kicked on, since the sensor is on the thermo cover side of the stat, the water was not warm enough to trip the fan.

I let the car cool overnight and will warm it up again today. Now that the thermostat plunger is free, I think I will have a better result!