Can you temp wire in a rad fan switch just to keep the temps down while you are going through the process?

Believe it or not, this is fairly typical for the NSX. Prime is littered with the woes of owners (and service folks) with air trapped in the system- it takes ages and ages to burp it all out. In my case, the system was totally dry, including the engine block. Then, I sucked air back into the engine block twice to change the thermostats. Most people who do the coolant change don't realize that a good amount of coolant stays in the car even after draining. After a complete overhaul, it's a different story.what a process...

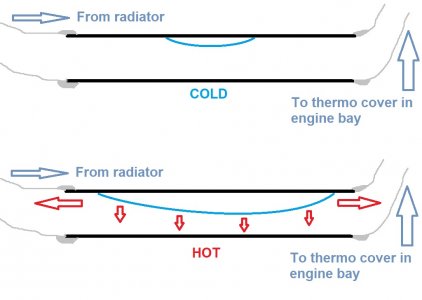

The rad fan process is actually a safety test to make sure there is a minimum of air in the system. If the coolant expands to the top of the bottle before the fan turns on (at the max temp the car will allow), it is a sign that there is too much air in the system and the car needs to purge more air before you can drive it. At idle/no-load conditions, the voids and steam pockets are not a danger to the engine as long as the coolant doesn't overheat (hence why I shut it down). But, when driving and under load, it's a different story- your head gaskets are at risk!

On the second warmup, I increased RPM to ~2,000 several times to help the water pump move the air bubbles to the bleeders. I fear I may have to do this several more times before I can get the air out...