NSX Type-S Zero Project - A Look Back

PART TWO - BUDGET

So, as discussed in Part One, this project was worth it. How many people get to drive a LHD Type-S, other than Zanardi owners? In a cool JDM color with new everything and Comptech power to boot. But, as one can imagine, it came at a cost. One of the most burning questions in this thread and elsewhere was simply: "how much did this cost to do?"

As I have advised other owners who are going down this long road, it's a really good idea to start with a concrete project goal and a

budget. Having a budget helps you make good decisions during the long journey and keep yourself out of trouble, e.g., ending up with a disorganized mess of a car and/or descending into an inescapable money pit. For example, budget was the reason I chose to forego the 6-speed in favor of a NSX-R 5-speed. Driving the car now, I could care less about the extra gear. Anyway, this project did have a firm budget.

When Mrs. Honcho gave me the green light for this endeavor, she made me promise three things:

- I could spend no more than what our 2013 GT-R cost: $75,000

- I had to be prepared to have the car sit in pieces for potentially years

- Neither the time or money spent could interfere with our family life, i.e., "the car comes last."

Taking these requirements to heart, I planned a project that would last 4 years factoring in a lot of downtime. I also put a high focus on re-using as many parts as possible from the original car and sourcing as much as possible from junkyards, Prime member favors/hookups and the JDM parts vendors where appropriate. Also, I resolved to do as much work myself as possible to save on expensive labor costs. It was this focus that really made the project possible.

Some ground rules and caveats before we dive into the numbers:

- Virtually all of the labor time is DIY. Paying someone to do this job would likely double the final cost- at least.

- Post-project items like the PPF, tuning and final touchups are not counted here. I consider those to be running/usage costs.

- Many of the parts prices included in these calculations have gone up significantly since 2018.

- Or, these parts have been discontinued. It will likely be much harder to do this project in 2023 than it was in 2018.

- Whatever your timeline is for your project, multiply it by 2 or 3 to get a realistic number. Most of the work done here was 45 minutes at a time, each night after the kids went to bed. Life gets in the way quite often, as it should.

- The biggest key to making this project work was finding a body shop that was willing to take on the job and work with me. I can't understate how critical this is. The wonderful folks at Franktown Restoration Garage were the real key here.

OVERVIEW

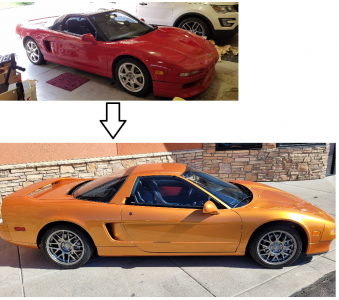

After spending months poring over my research, I determined that it would cost about $50,000 to do the job as originally planned. With a budget of $75,000, that meant I had to find a NSX for $25,000 or less. In 2018, that was quite difficult, but I lucked into finding a 92 AT on Autotrader of all places. The car was rough, but again because I had a firm goal and plan, I knew I could overlook all that stuff. What I really needed was a straight body. The rest was going to be replaced/refinished anyway.

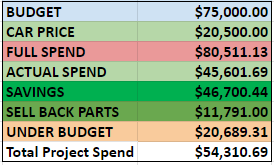

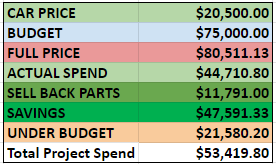

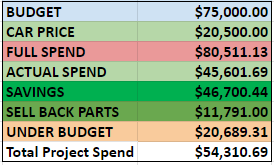

Here are the overall numbers:

Overall, I spent

$54,310.69 out of pocket on this project, which includes the price of the car itself. I beat my budget by $20,689.31!

The car was a gem of a find, as I was able to scrape it up for $20,500. This left even more room in the budget. Based on what went into the car, it would have cost $80,511.13 if I paid full price for everything and just did a huge order from Honda/Acura. By working the junkyards, vendors like ATR and MITA, Prime members, etc., I was able to knock this spend down to $45,601.69. This was massive. In addition, I was able to earn $11,791 back by selling parts off of the car that weren't needed for the project. That money is still coming back in, as there is some stuff left in the Prime marketplace.

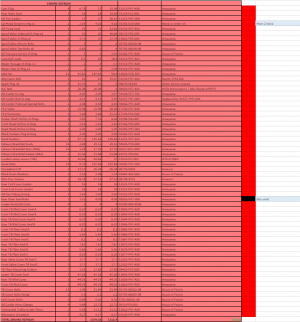

BREAKDOWN

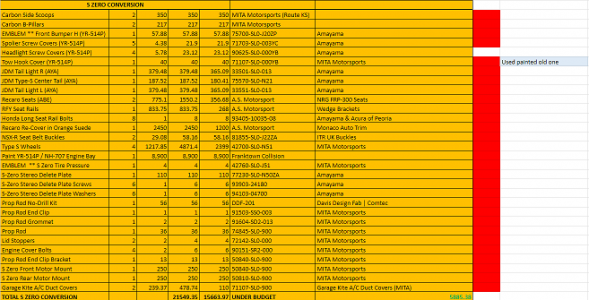

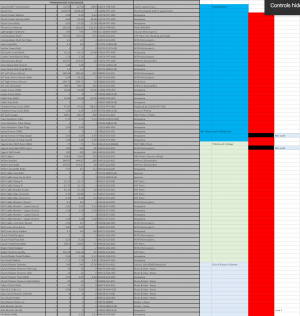

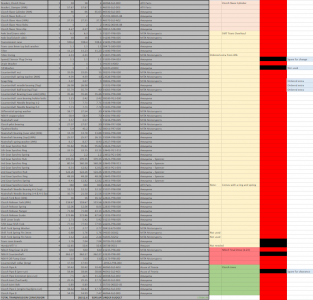

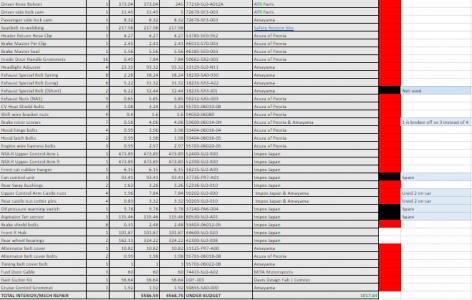

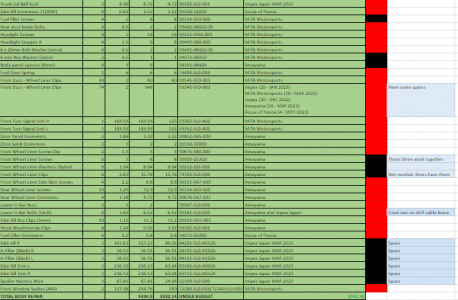

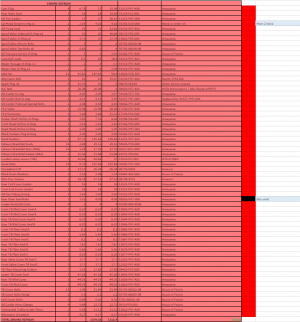

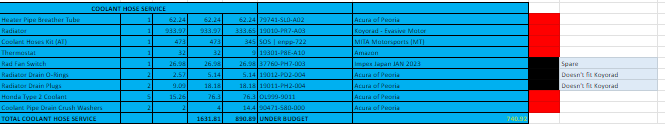

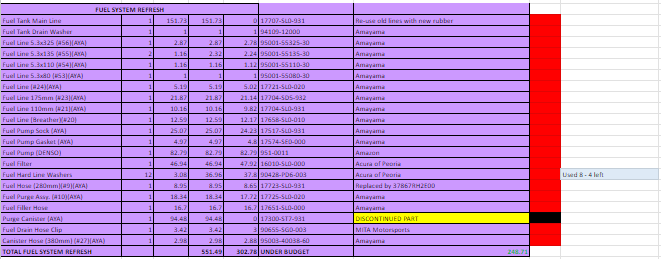

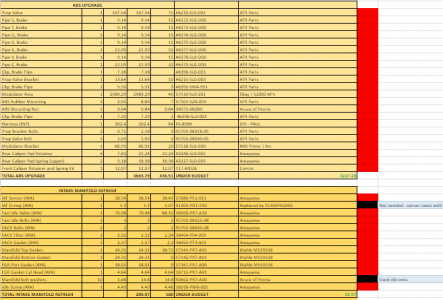

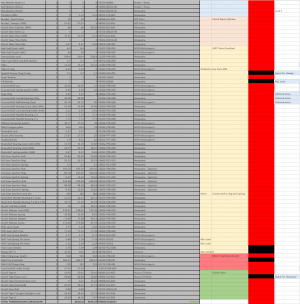

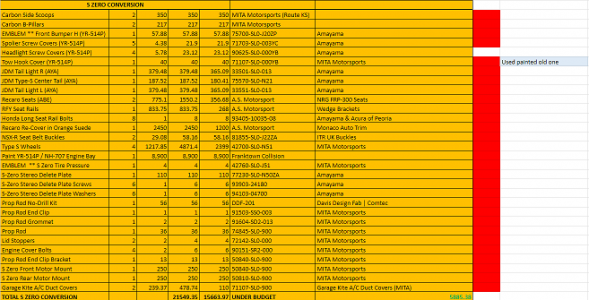

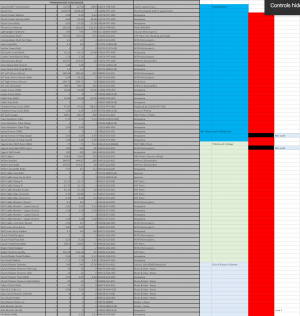

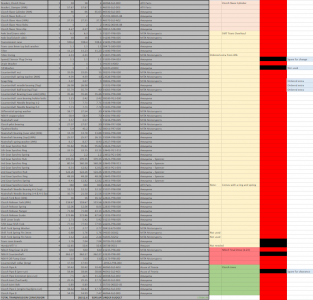

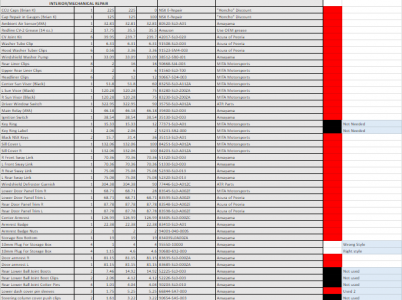

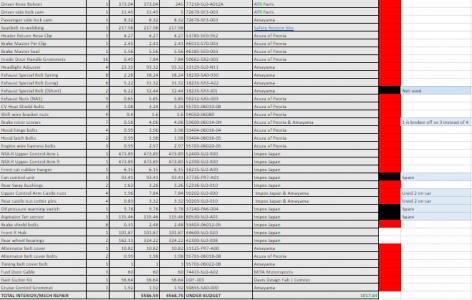

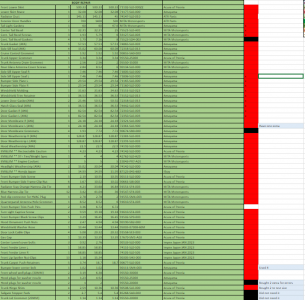

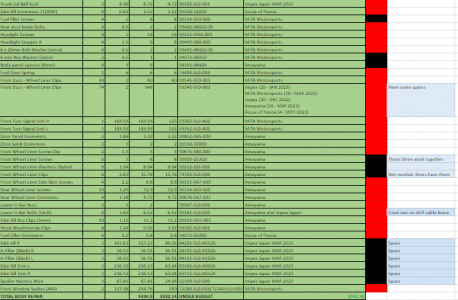

It was important to stay organized with a project of this scope and scale. I maintained spreadsheets of costs and divided them into rough categories below. Also, I used a bag system and a coding on these charts that added a red box next to a part once it was installed on the car. This helped me understand what was still in bags versus what was on the car. It ended up being

VITAL. Still, if I did this again, I would add the date of the order in the description box for each parts. You can see I started to do that in 2022/23. It would have greatly sped up searching for stuff, which cost me hours and hours over the life of the project.

Body Repair - This covered all parts required to repair exterior areas of the car.

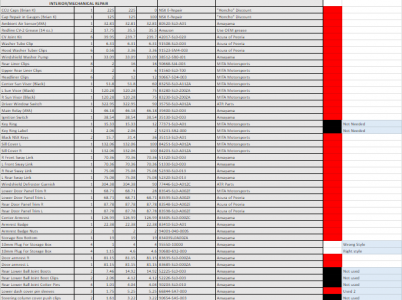

Interior/Mechanical Repair - This covered the interior and all mechanical replacements.

Coolant Service - Included the radiator and hoses

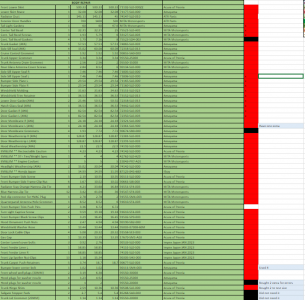

S Zero Conversion - Items/services needed to turn the car into the S Zero spec

Fuel System Refresh

ABS Upgrade

Intake Manifold Refresh

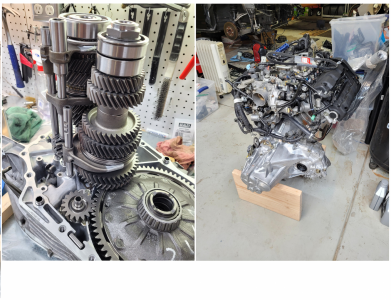

Transmission Conversion - Everything needed to go AT --> MT, plus rebuild

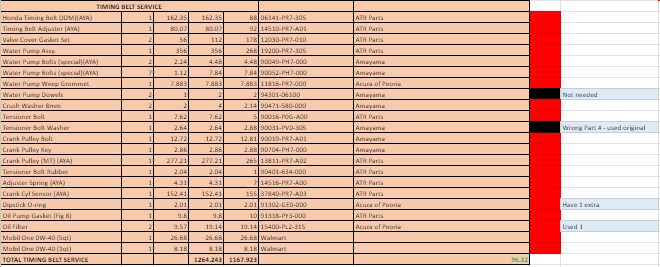

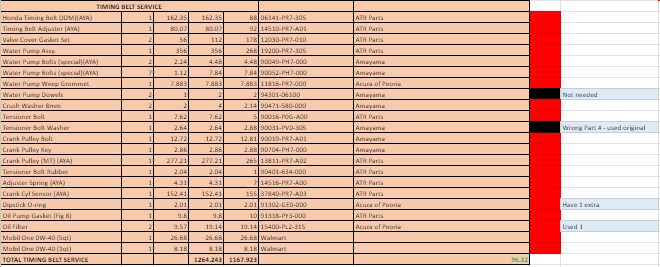

Timing Belt Service - My standard service for the TB/WP

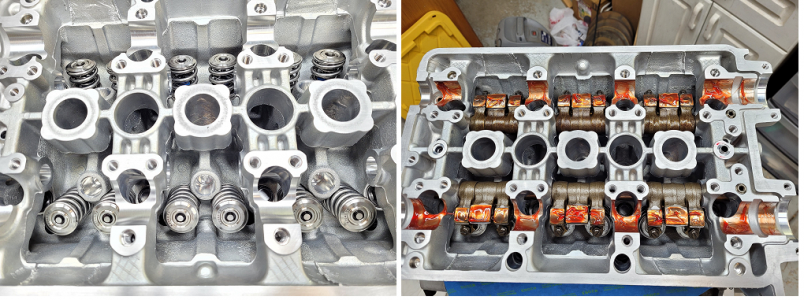

Engine Refresh - My "Stage 2" refresh, where the heads come off.

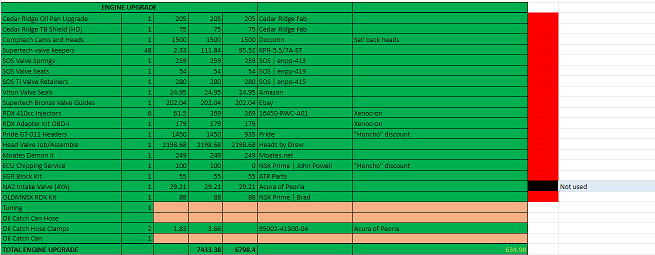

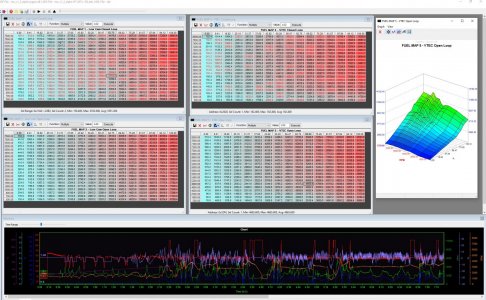

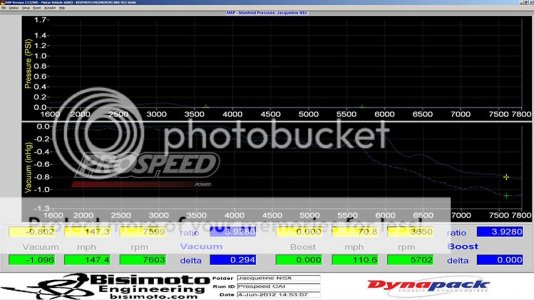

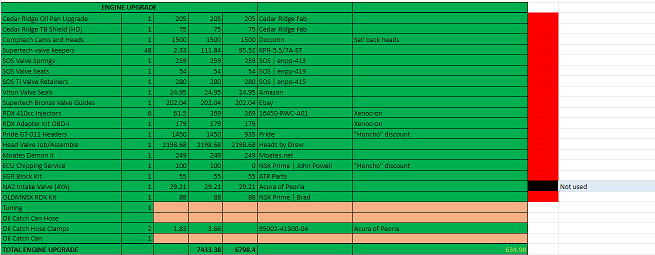

Engine Upgrade - Everything needed to accommodate the Comptech cams and tuning

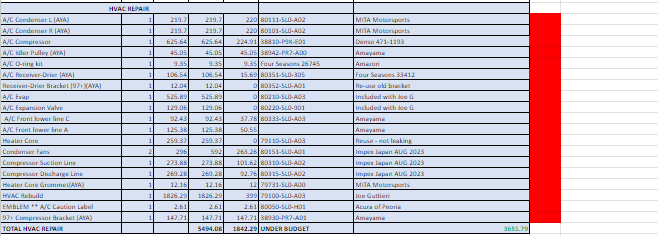

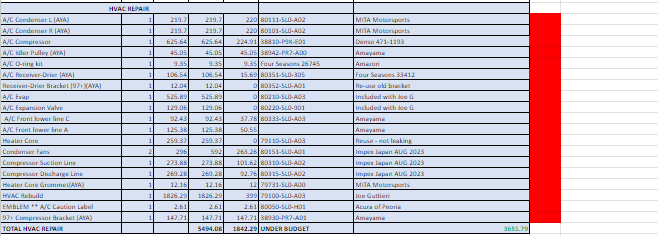

HVAC Repair

At

$15,663.97 in actual spend, the S Zero conversion was the most expensive part of the project. This is primarily because it included the repaint and expensive items like the S wheels and seats.

The next most expensive area was the AT to MT conversion at

$9,245.64. Although I got my 5-speed super cheap and the clutch for free, the cost to build the trans to the NSX-R spec and replace all the internals was quite expensive.

Next most expensive was the Engine Upgrade at

$6,798.40. Engine work is expensive on the NSX and here, most of the cost was in the head work needed. To make the most of the Comptech cams, the 3.0 engine needs the larger 36mm intake valves. My valve guides were also shot and out of spec, so bronze guides were needed. The cams also necessitated using the Supertech titanium retainers and up-rated springs from SOS.

The 92 NSX was in rough interior and mechanical shape, so many replacement parts were necessary. Total cost came in at

$4,568.75. In retrospect, I would have separated the interior refresh out from this section.

Next most expensive was the body repair. The exterior of the car, despite the repaint, needed a lot of work. Total spend was

$3,392.14.

Next, believe it or not, was the HVAC work at

$1,842.29. Mostly because I had to replace my condenser fans and compressor lines recently, which added to the cost. This is an area where my budget focus hurt me- I re-used parts I thought were ok but turned out to be bad.

Prime members should be interested in the next expensive section, which constitutes my personal Engine Refresh service. The TB/WP job itself cost

$1,167.92 and the refresh service, including replacing the head gaskets, was

$1,112.40. Remember that this is parts only, all the labor was my own.

Finally, the smaller items came in at: Coolant Service

$890.89, Fuel System

$302.78, ABS Upgrade

$436.51, Intake Manifold

$180.00.