Haha! Dave, I don't think half those people (including me) even knows what a

compound turbo setup is!

Quick question, been meaning to ask you... For a stock 3.0L @ 100k miles what oil should I be using?

Sorry - too many variables. I monitor oil temps in my pan - do you have a temp sensor that can measure the hottest oil temps? I'm thinking about using Mobil1 Racing 4T 10W40

motorcycle :wink: oil after break-in for street driving in warm ambient temps. Like others have said, the Mobil1 0W-40 oil should be good too.

- - - Updated - - -

Dumb question but is a compound turbo the same as a sequential turbo? If not, why? Advantages, disadvantages?

Please, for the little folk.

Good overview in this link. Compound turbo arrangement is described on the bottom of the first page:

http://www.autozine.org/technical_school/engine/Forced_Induction_3.html

- - - Updated - - -

Did you find a machine shop near you Dave?

Yes, at a place that specializes in European engines... but my arrangement with the bearing company to test their product is based on me sending them my crank and rods so they can ensure the machining and parts conditions are to their highly accurate standards. We're just looking at the rod bearings for now - not the mains.

In the meantime I'm still cleaning old engine parts!

- - - Updated - - -

Compound turbo is very tricky to tune that's what boostlogic tuner told me when I got my car tune

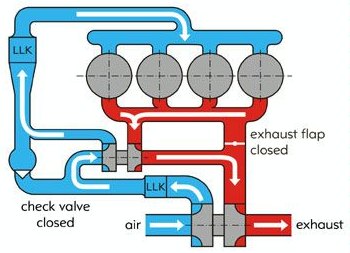

Yes, boostlogic was pretty much the pioneer in this area. However, the trick to seamless turbo integration is the exhaust and intake valves used for the transition. I'll be using OEM valves sourced overseas :smile:

My friend already has his components ready.

- - - Updated - - -

I like my supercharger. I have the SOS Kenny Bell supercharger with the SOS inter cooler.

At high rpm a turbo can make more power but at Low rpm the supercharger is wicked.

I track my car regularly. Coming out of a corner my car is amazingly quick.

For street use "light to light" I would think a supercharger would be a better fit.

What do I know.

Sounds like you have a neat setup that's a lot of fun!

There is no perfect FI system based on performance, cost, and complexity. For our individual needs we need to make compromises. However, I think Dave D.'s twin turbo arrangement using the variable geometry turbos is the best FI setup right now. It's no secret that Aerocharger went out of business awhile back due to a few technical issues and people using them beyond their intended design constraints (overboosting them). However, they've been redesigned, and Dave has been testing them. So far after two years of tracking and I forget how many thousands of miles, it is working great. His torque plateau has the widest RPM range of any NSX turbo setup I've ever seen, and he can easily get to 450WHP on his stock 3.2L if desired.

I just like to do stuff differently. I'm an automotive DIY amateur that's learning as I'm going. Since I'm still slightly hesitant about even the new Aerocharger's longevity, I'd like to try something I don't think anyone else has for the NSX - a compound arrangement. It just so happened that a friend and co-worker of mine is doing the same thing to his newish daily-driver S4. It definitely presents a new and unique challenge.