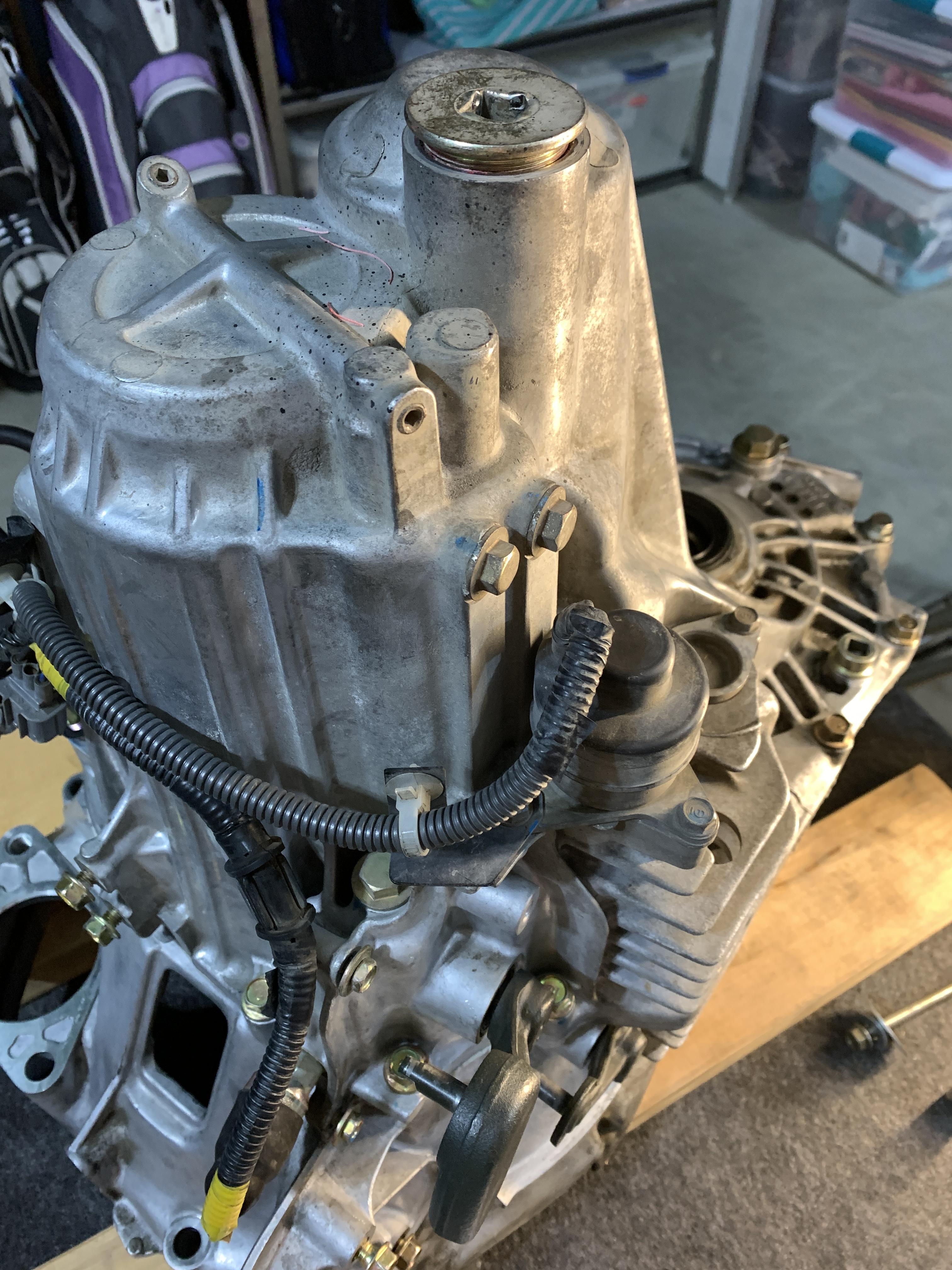

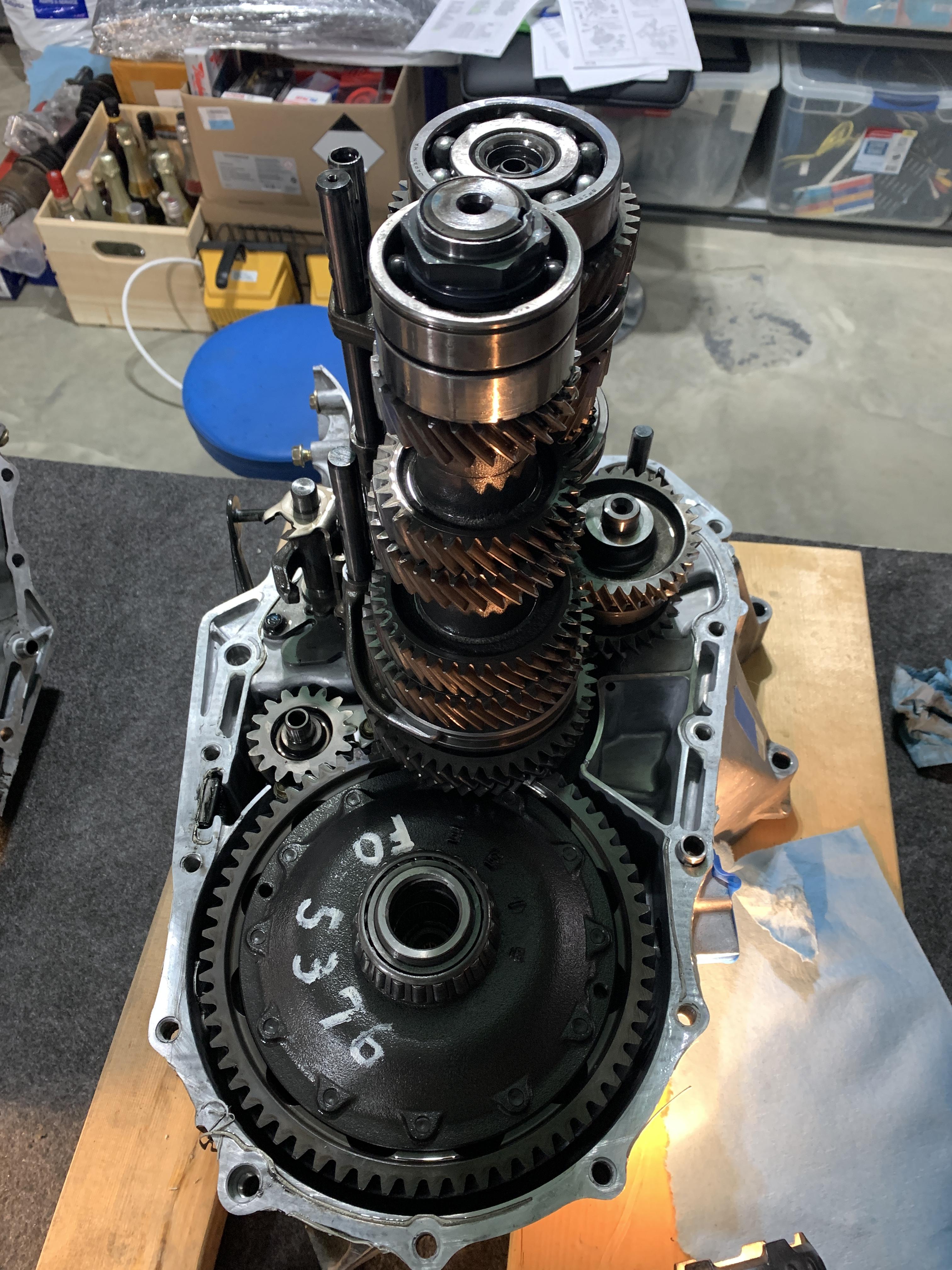

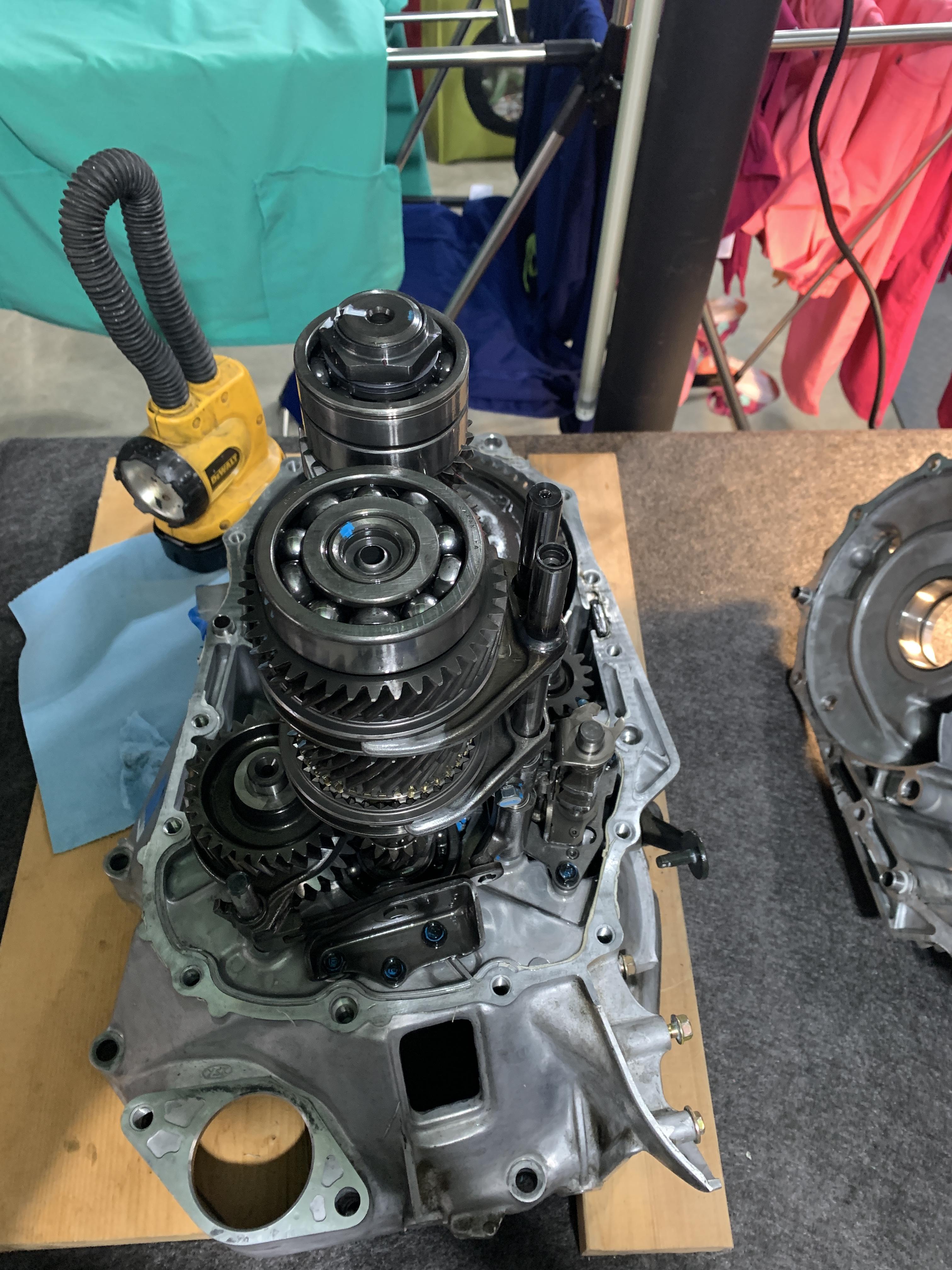

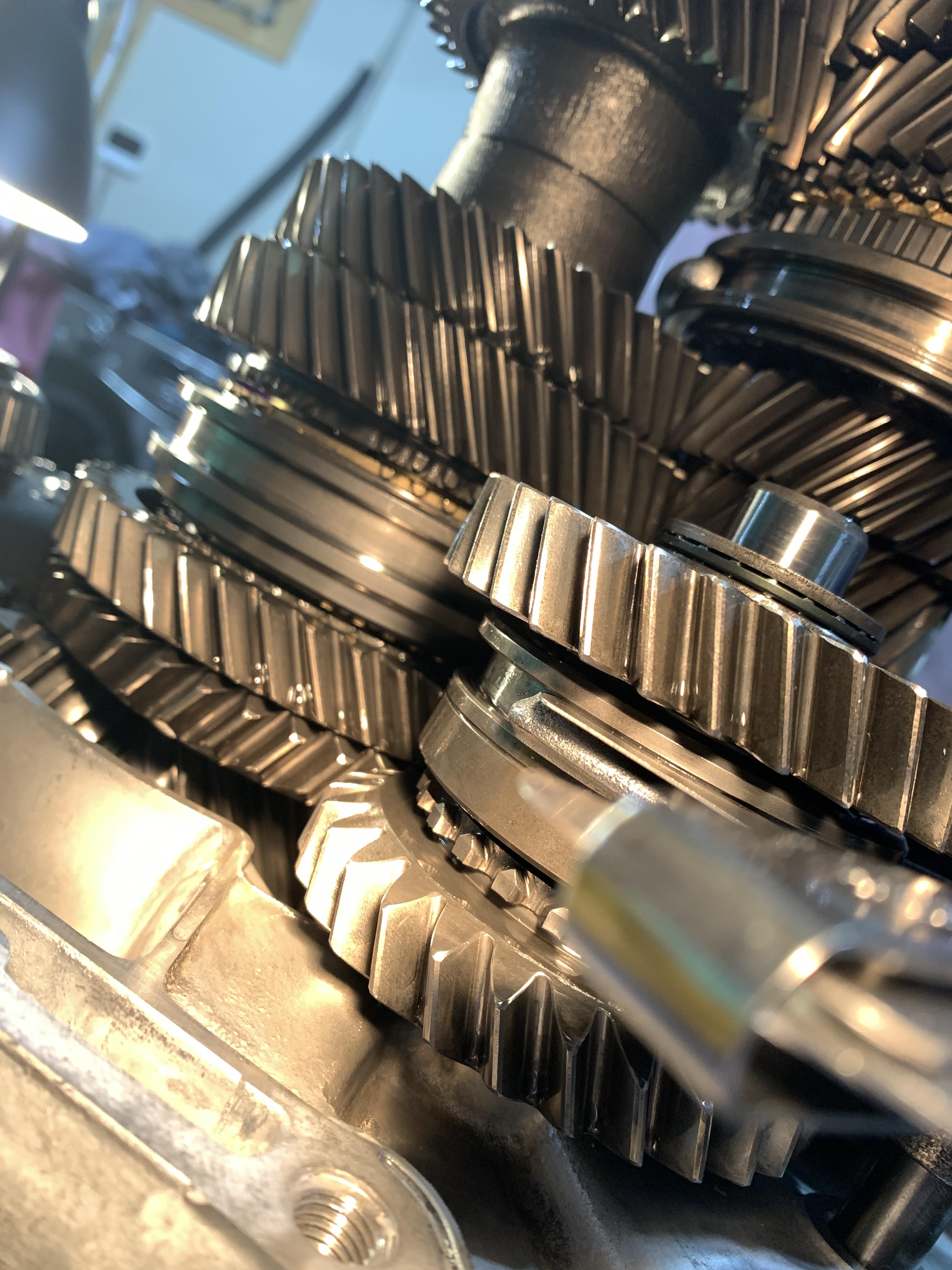

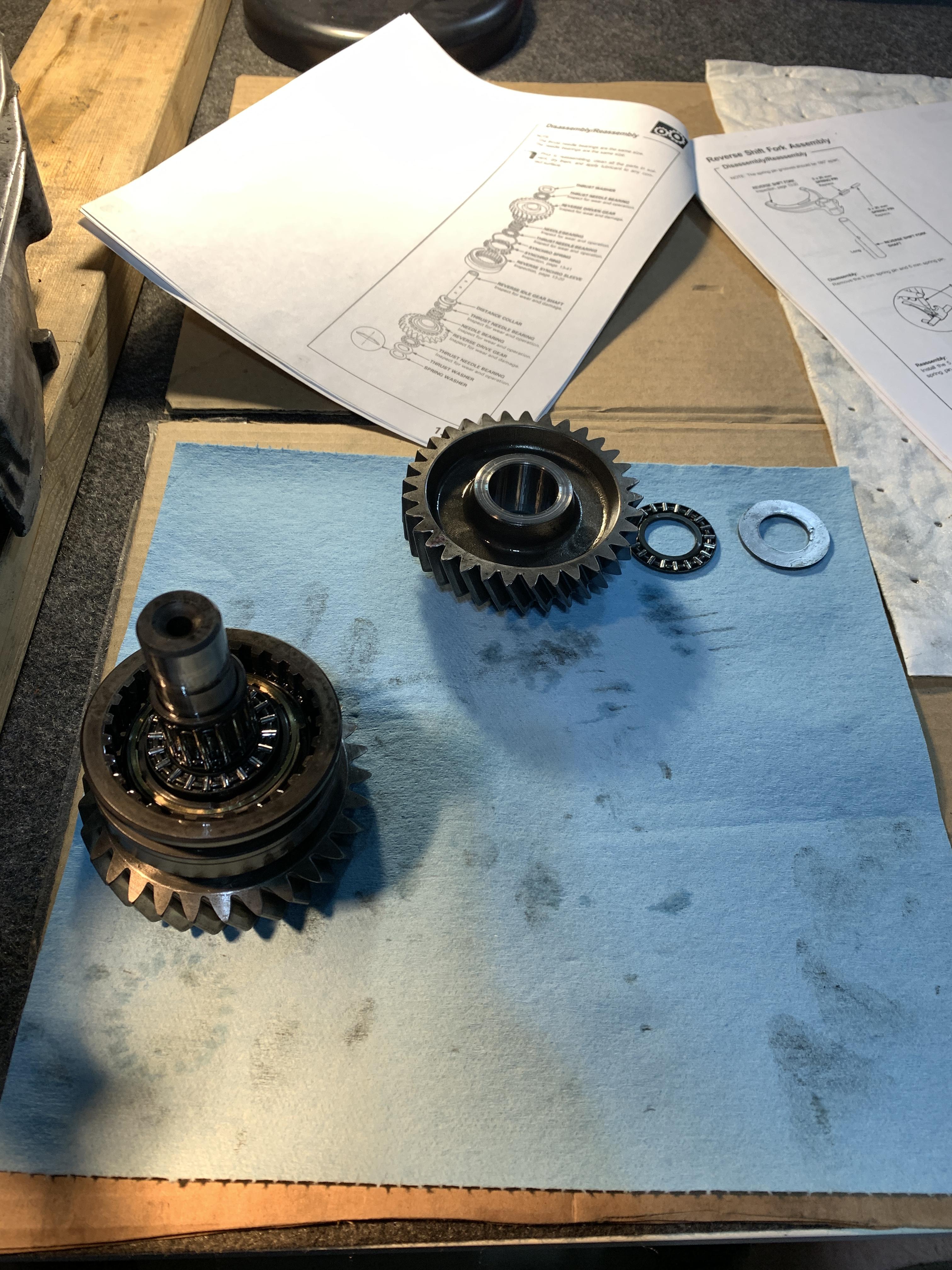

Also, there are so many "while you're in there" things I would consider. However, I also know how quickly the price ramps up and you get to a point of diminishing returns per dollar spent. BTW.. I just spent a small fortune just for new OEM 6spd parts like bearings, shims, etc... It's crazy how much all of that stuff adds up.

Some parts come to mind.

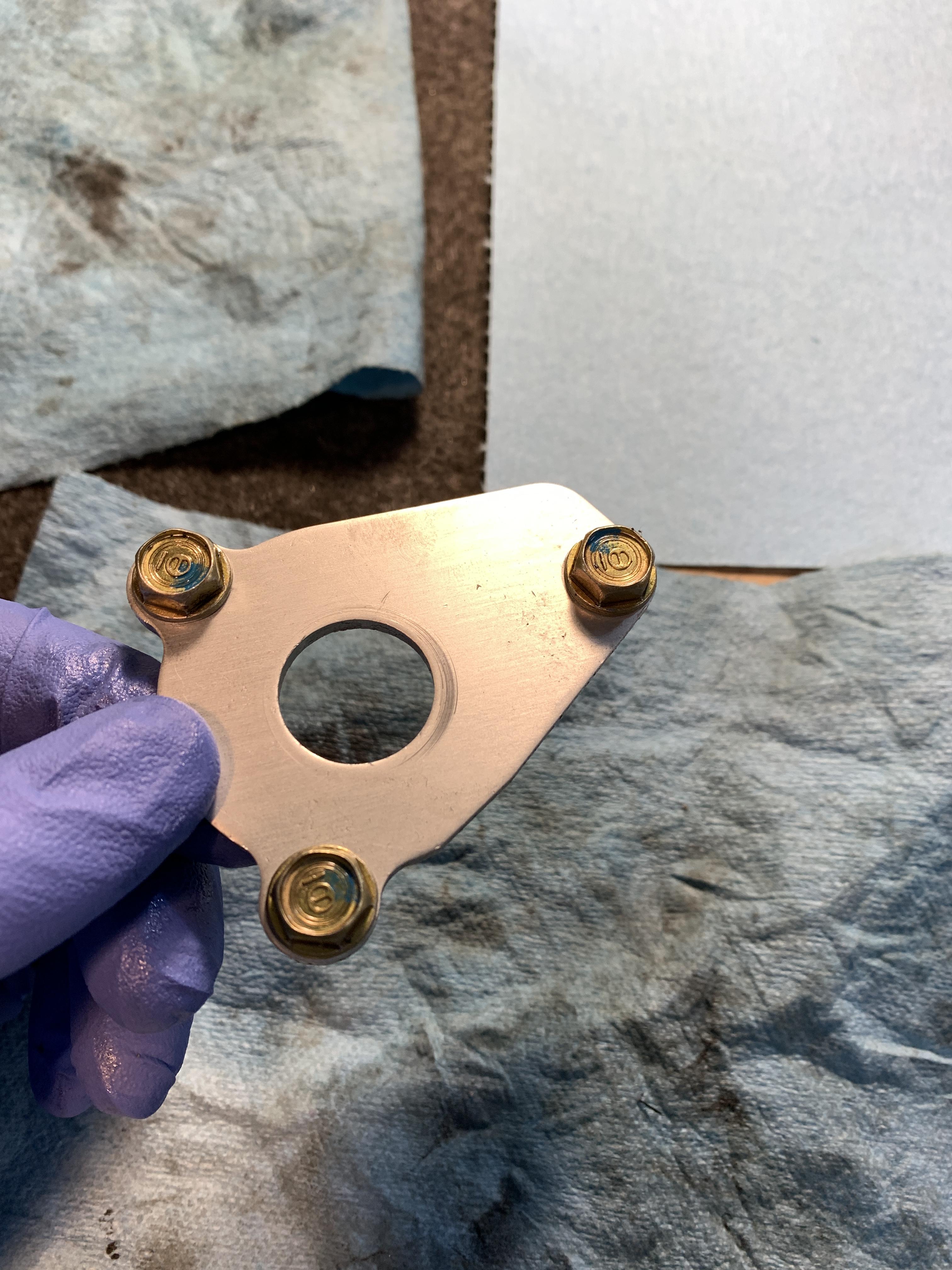

- Main crank pulley shield

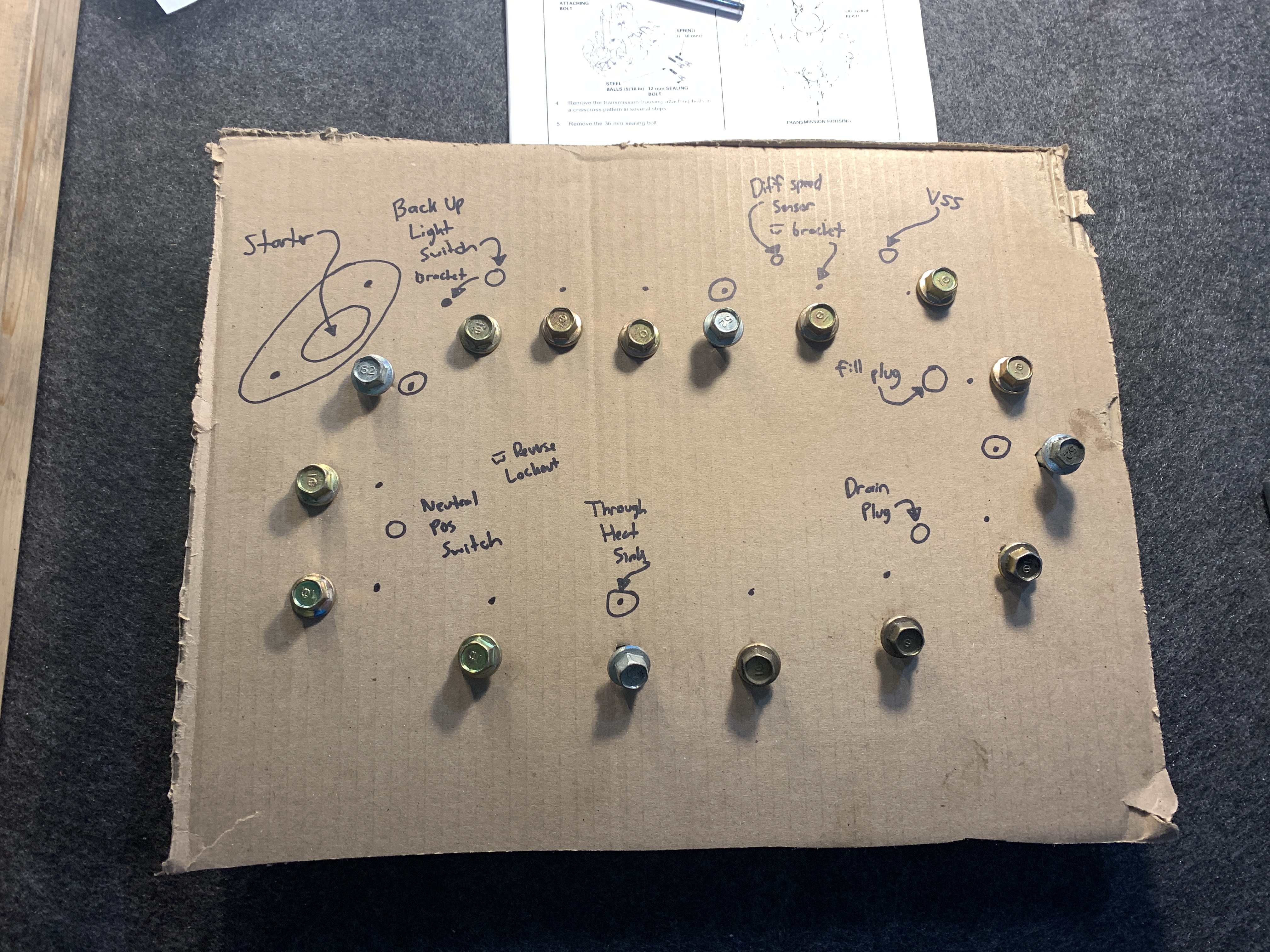

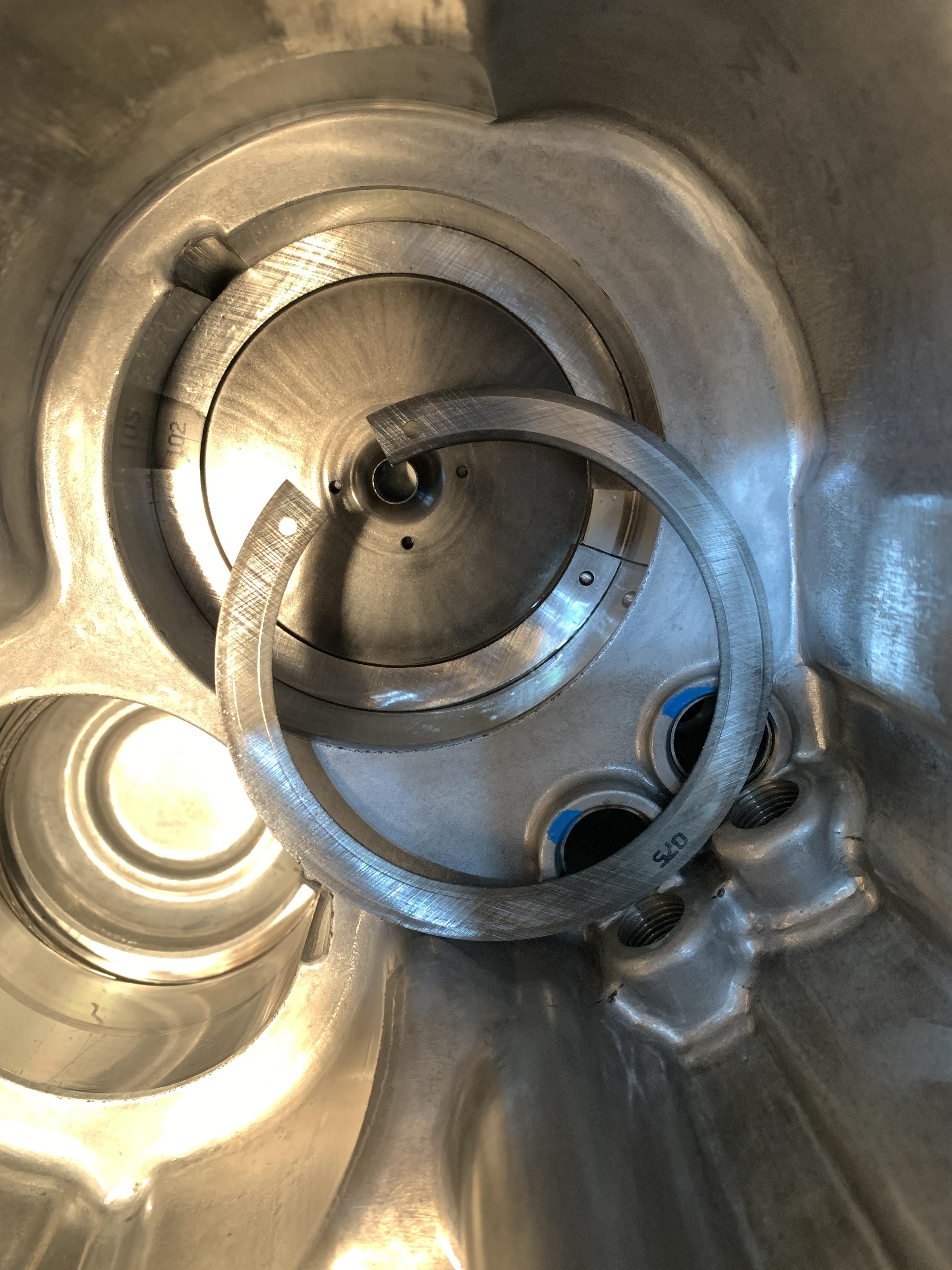

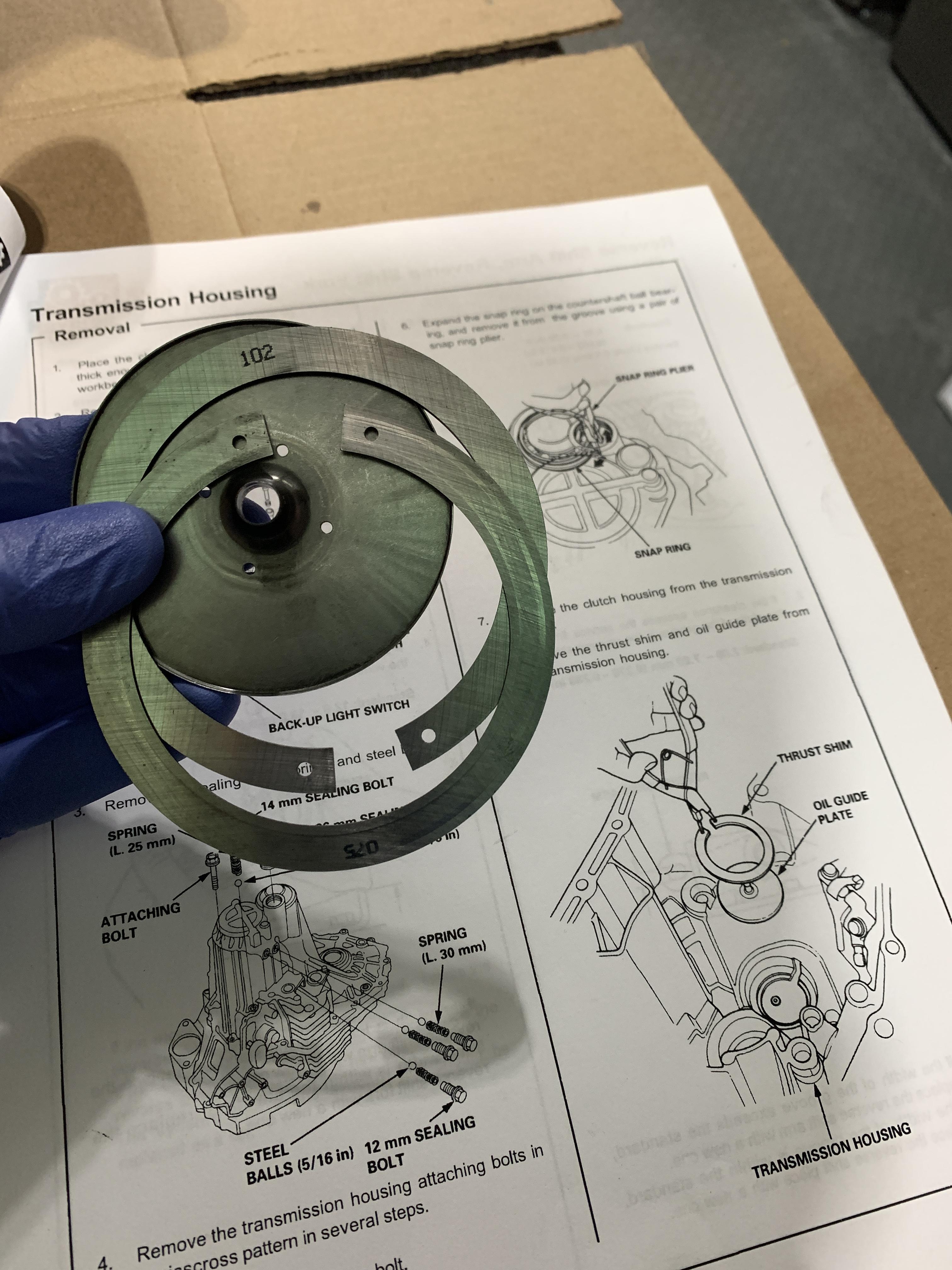

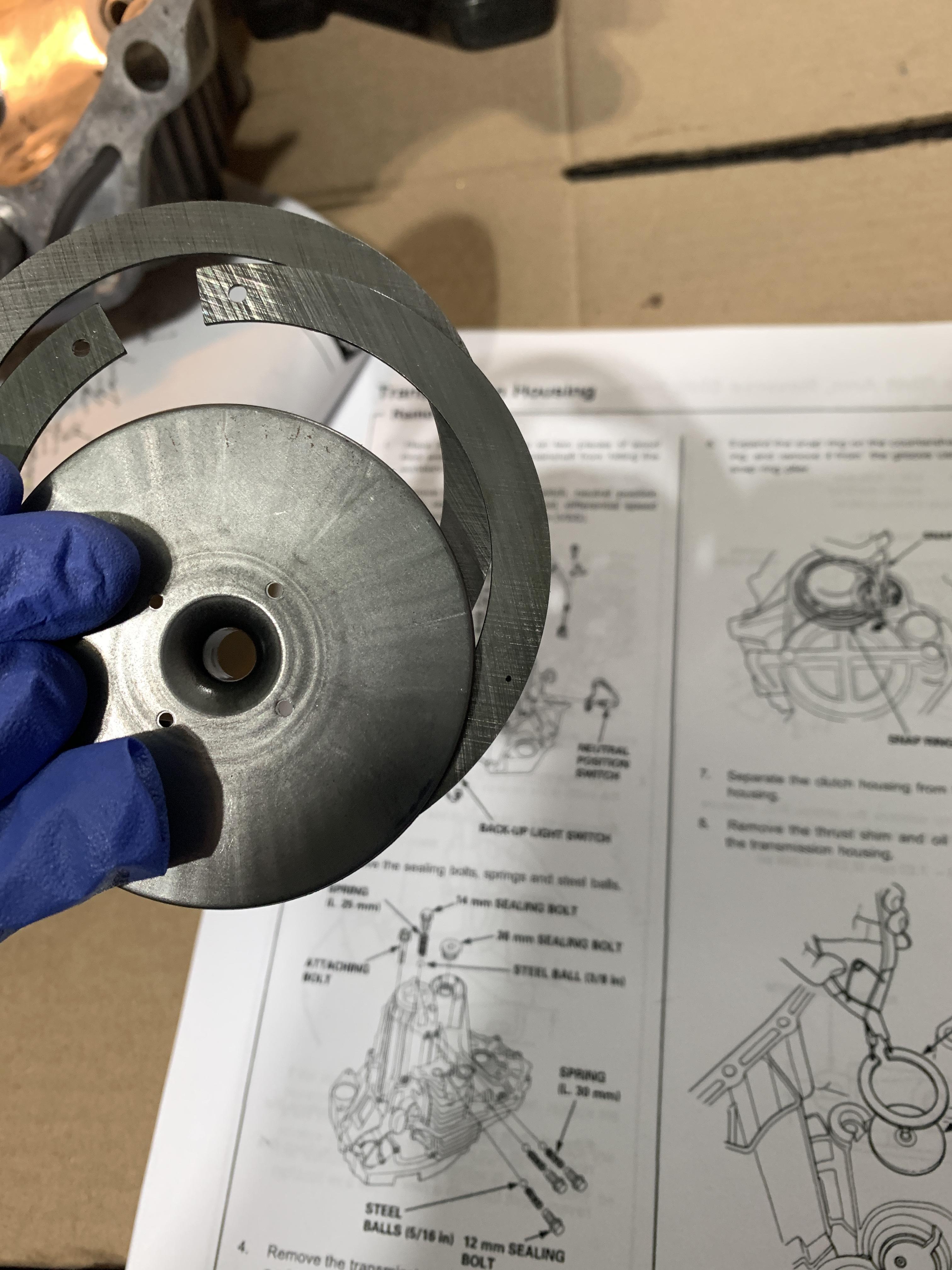

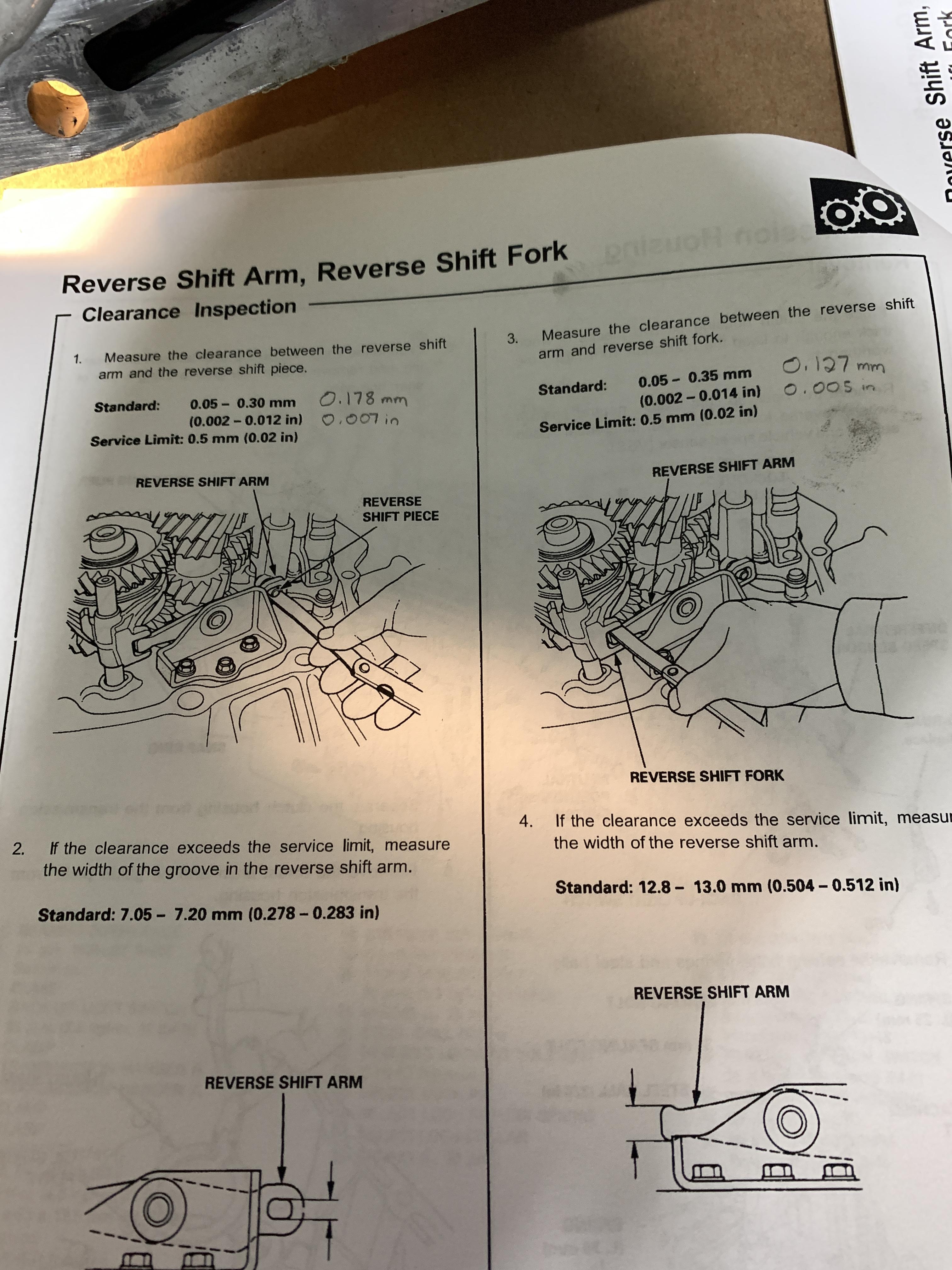

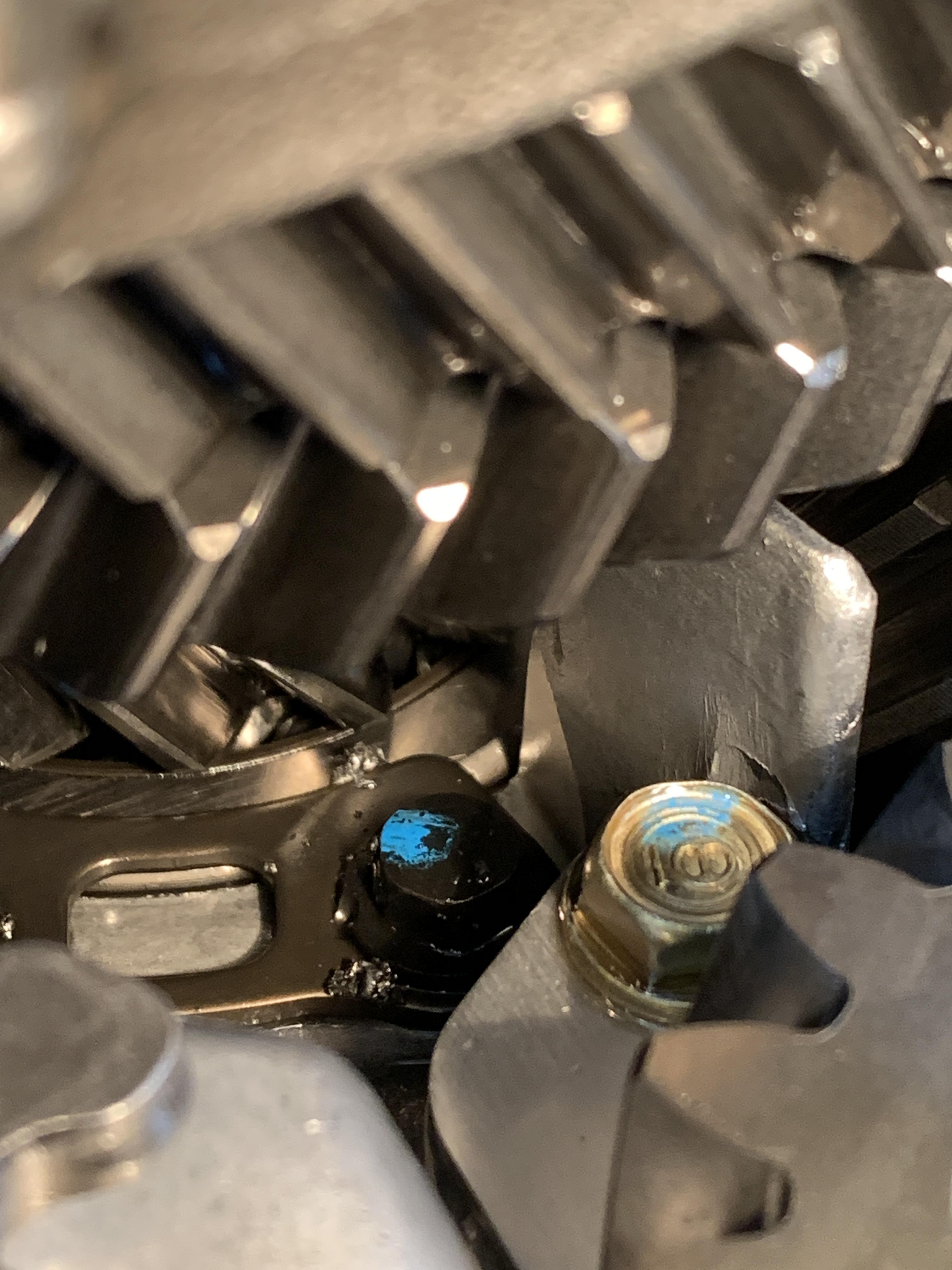

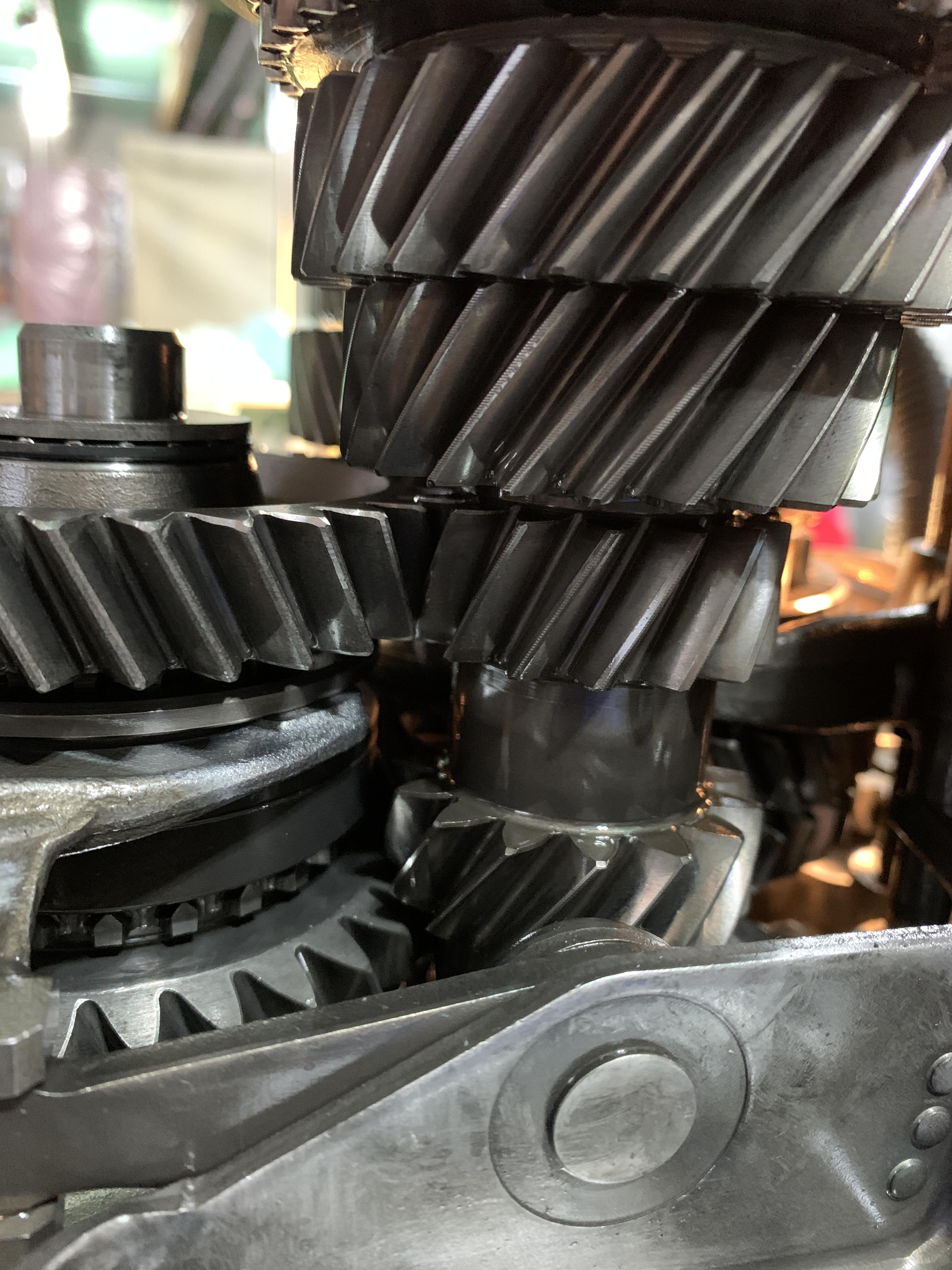

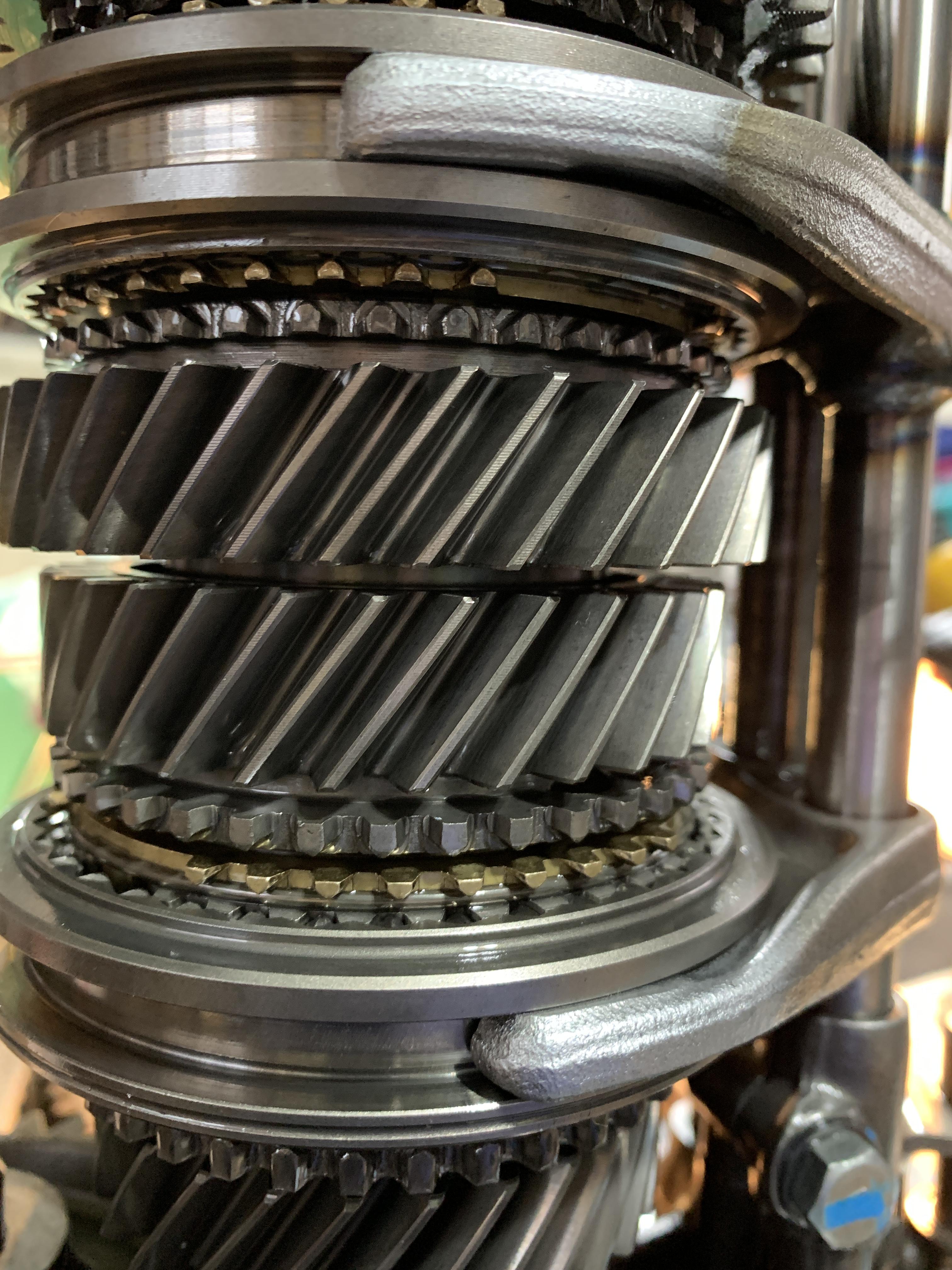

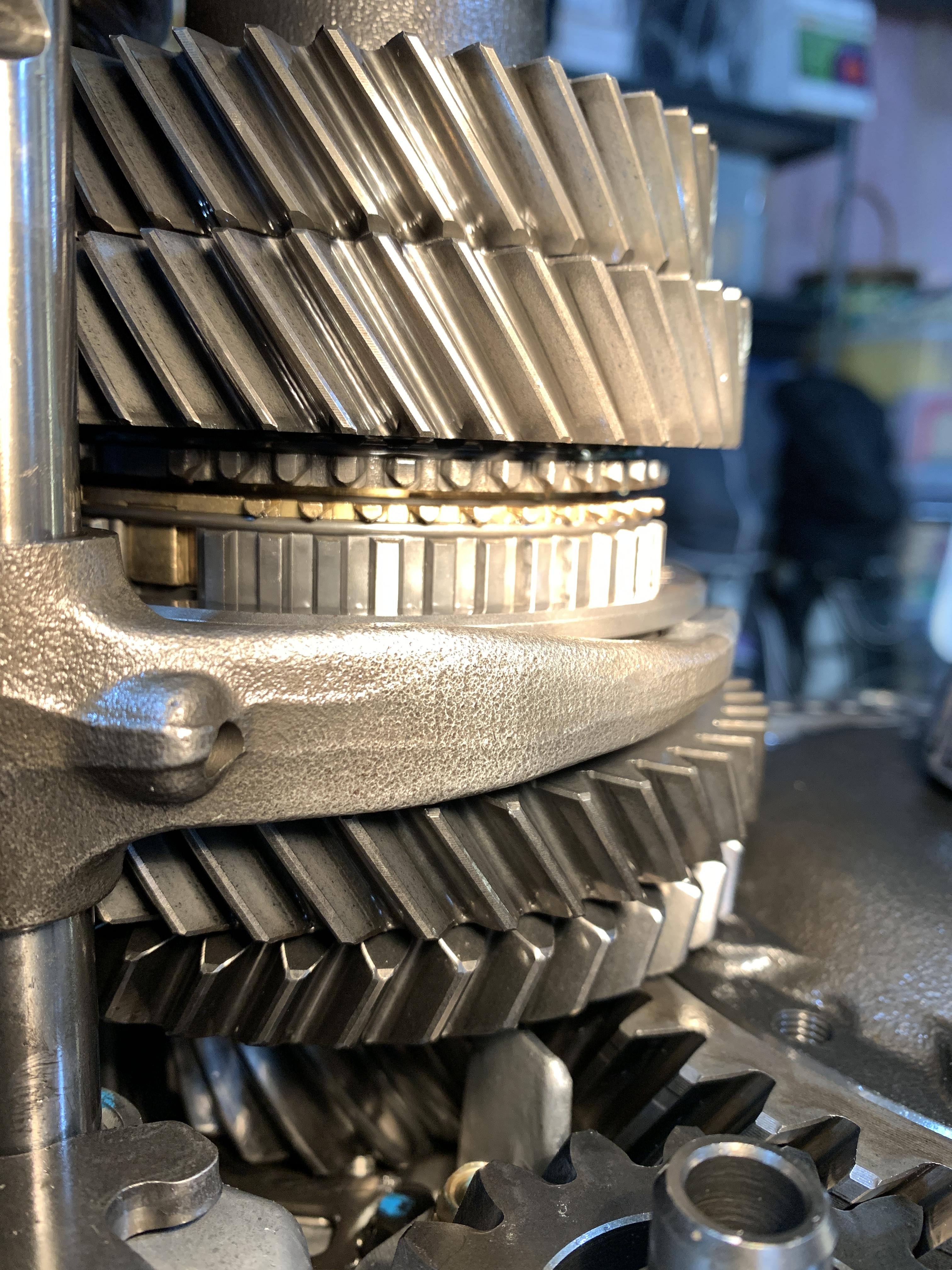

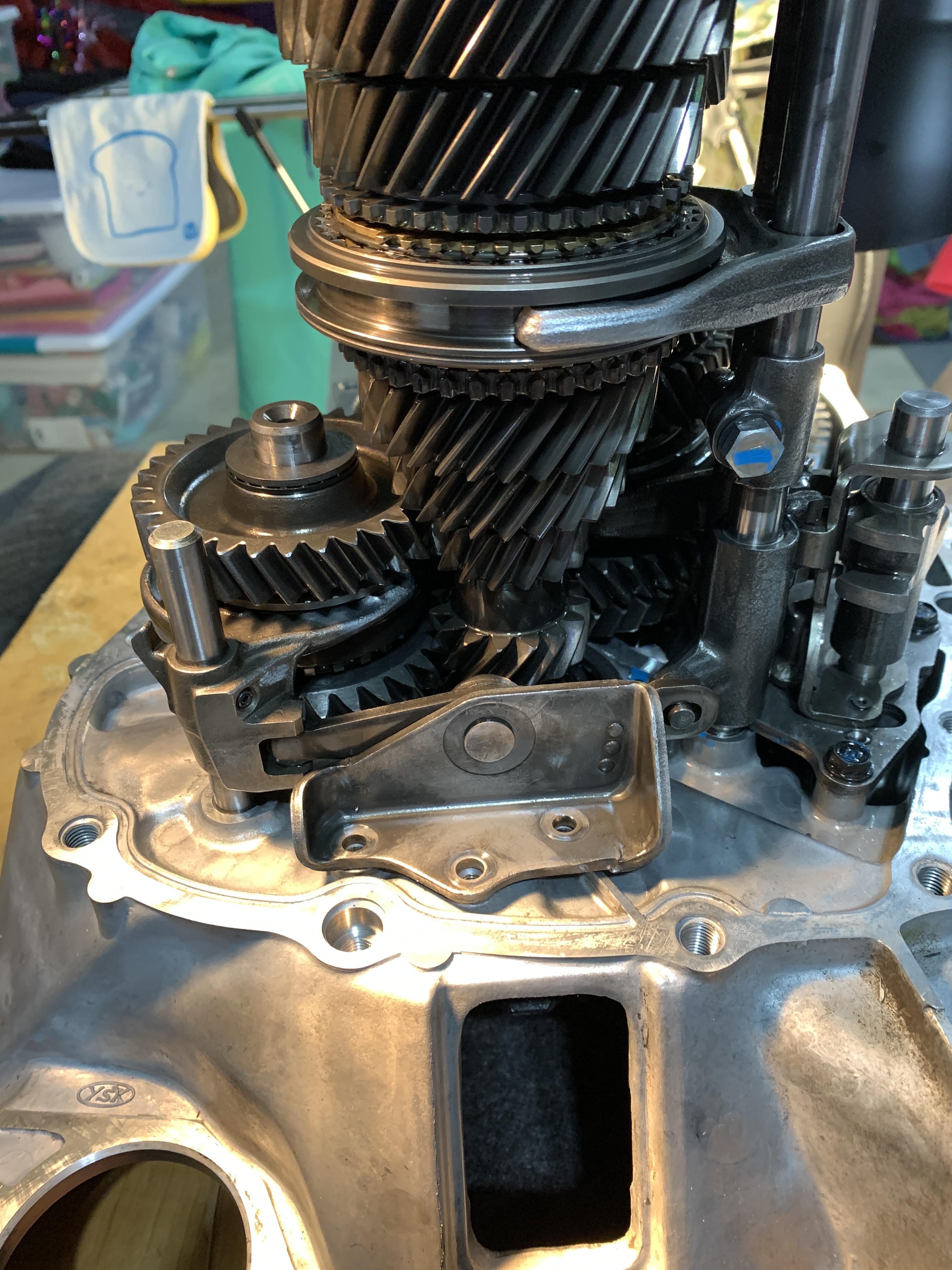

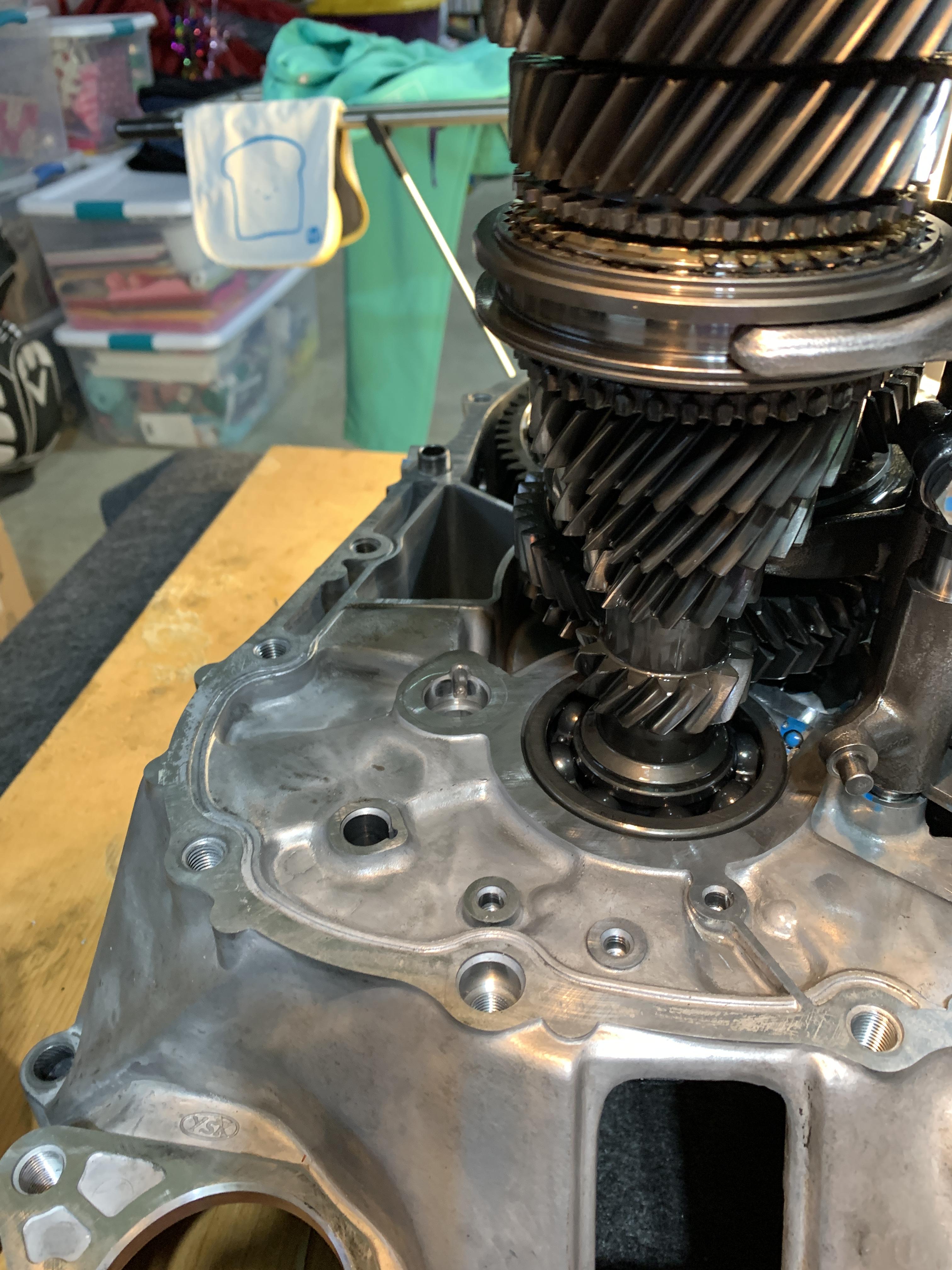

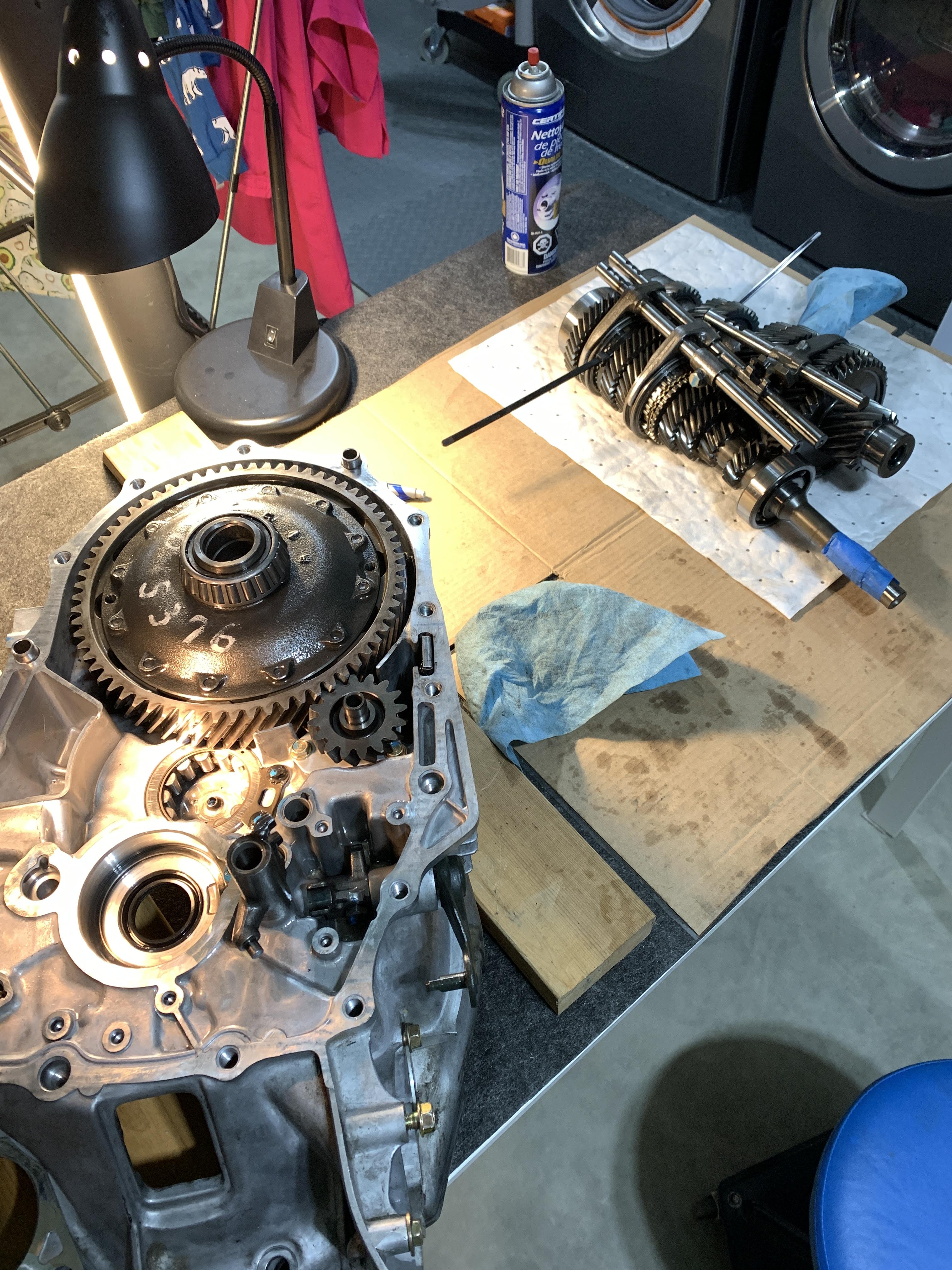

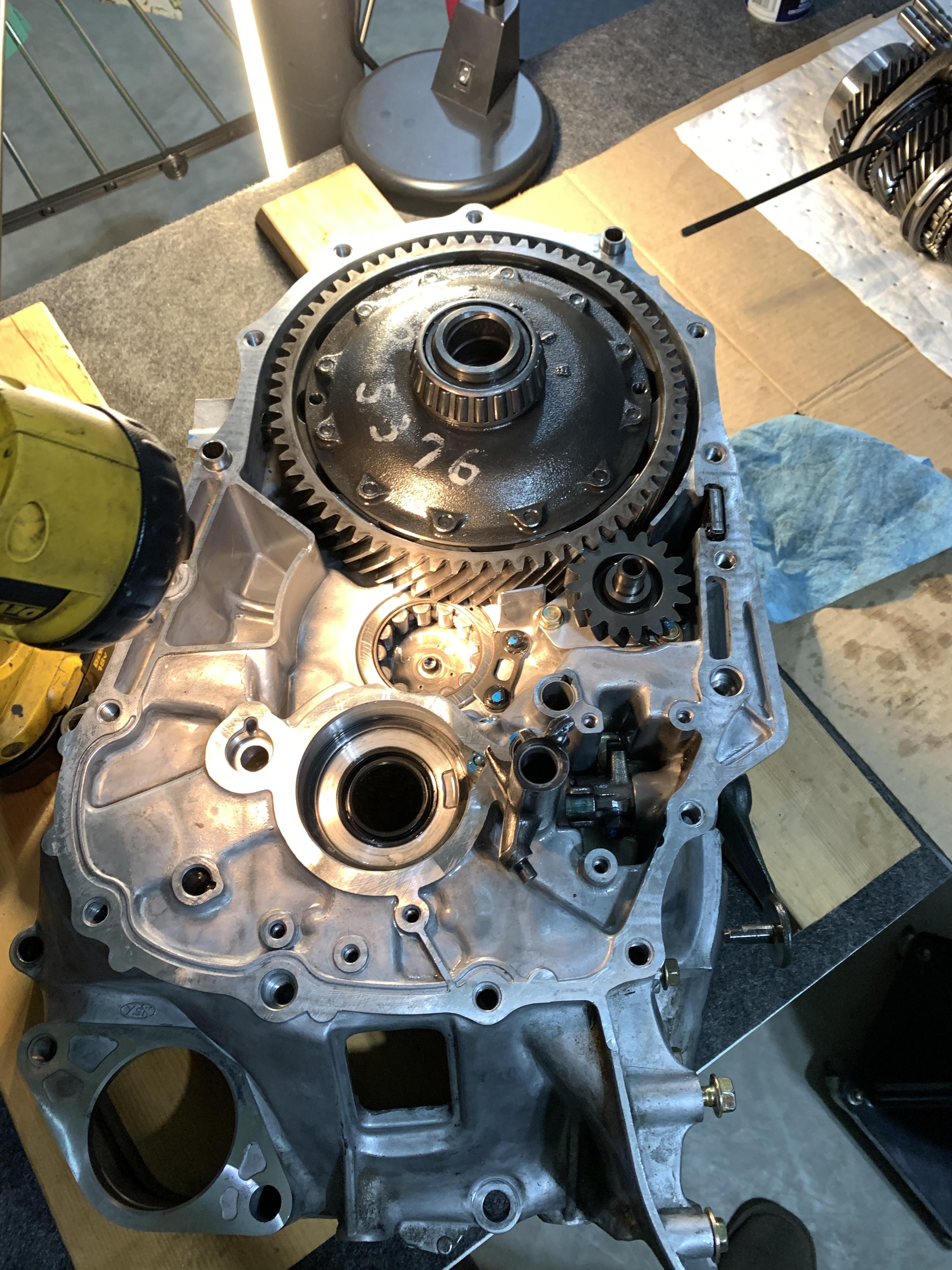

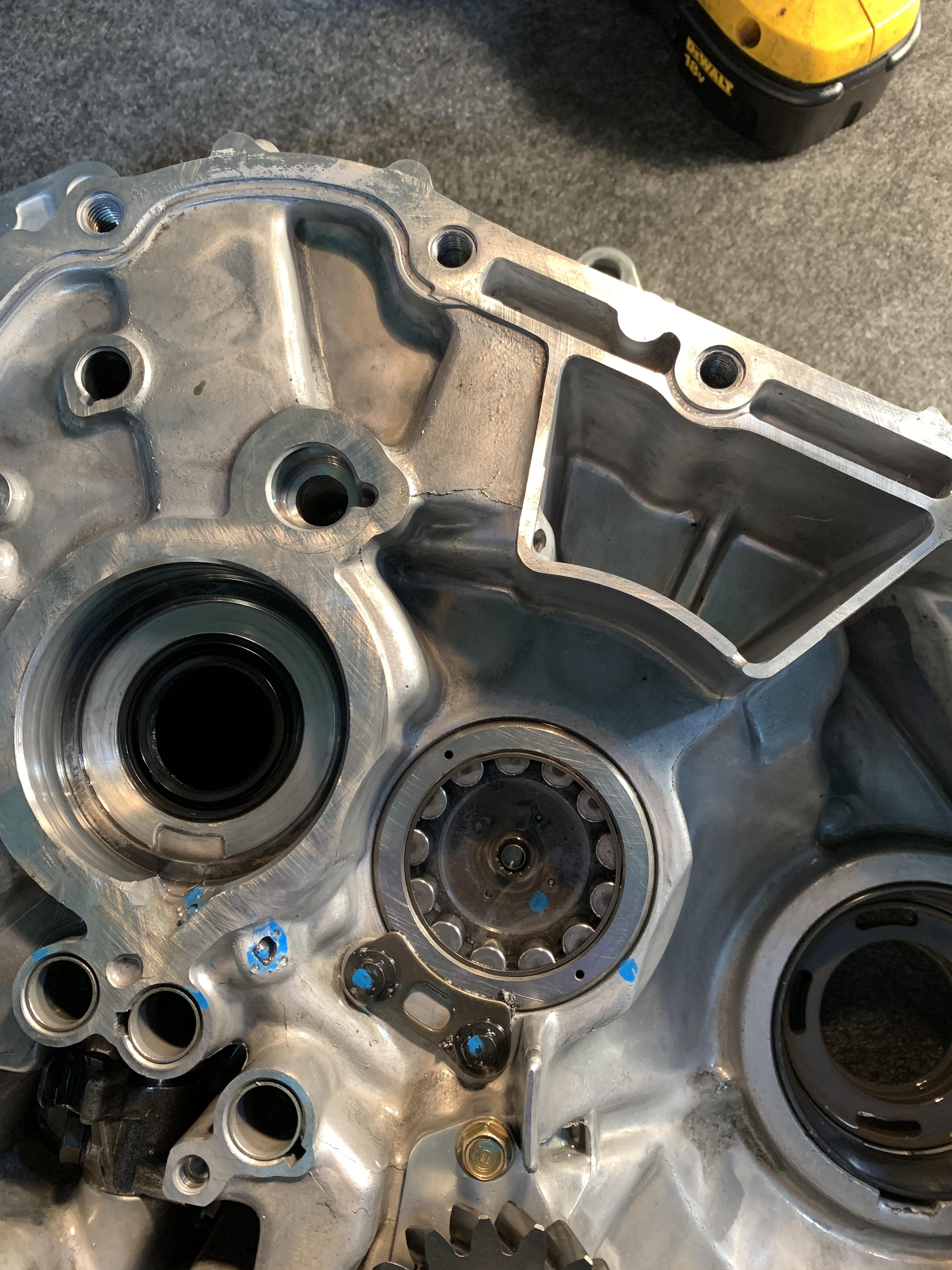

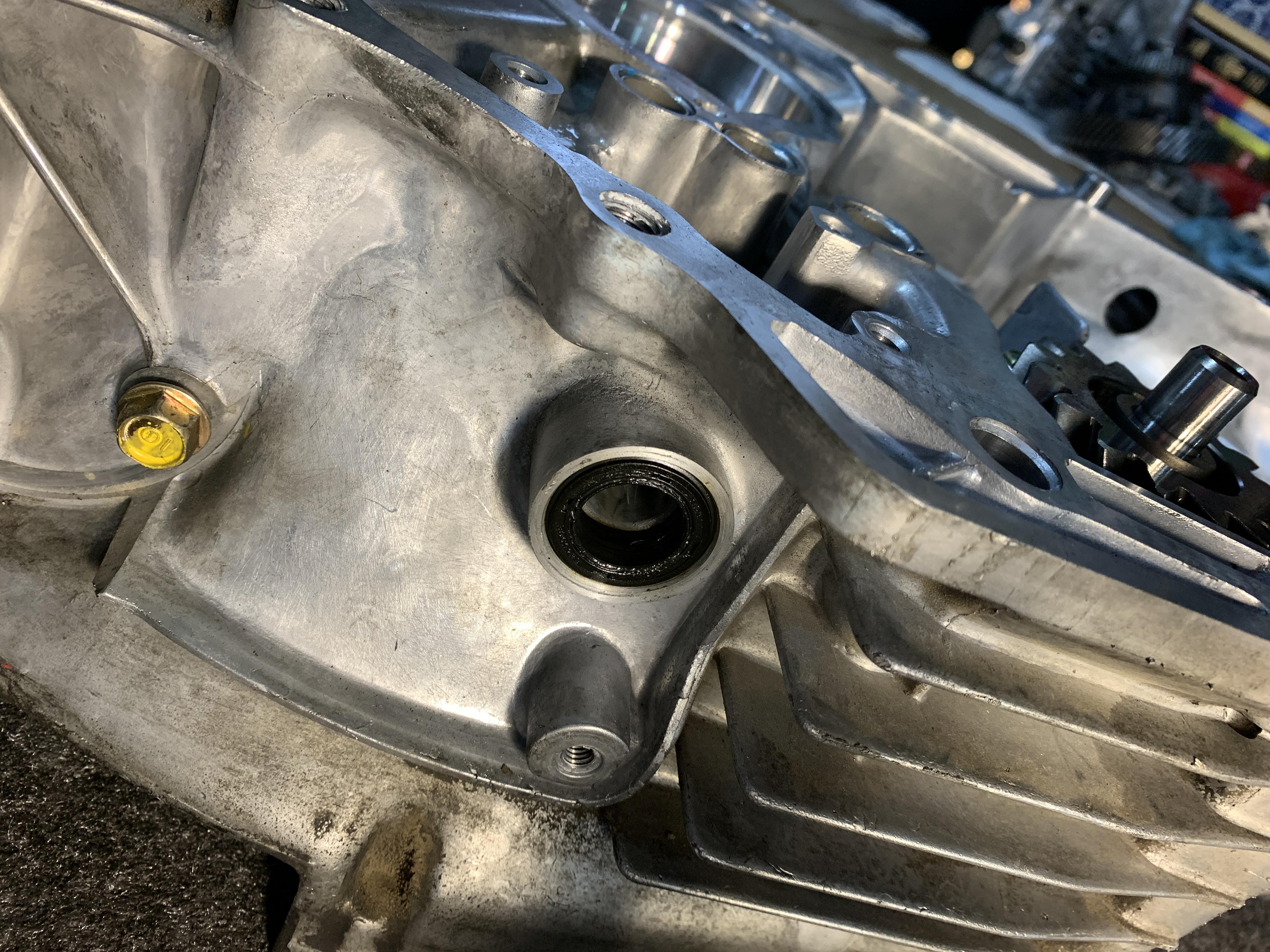

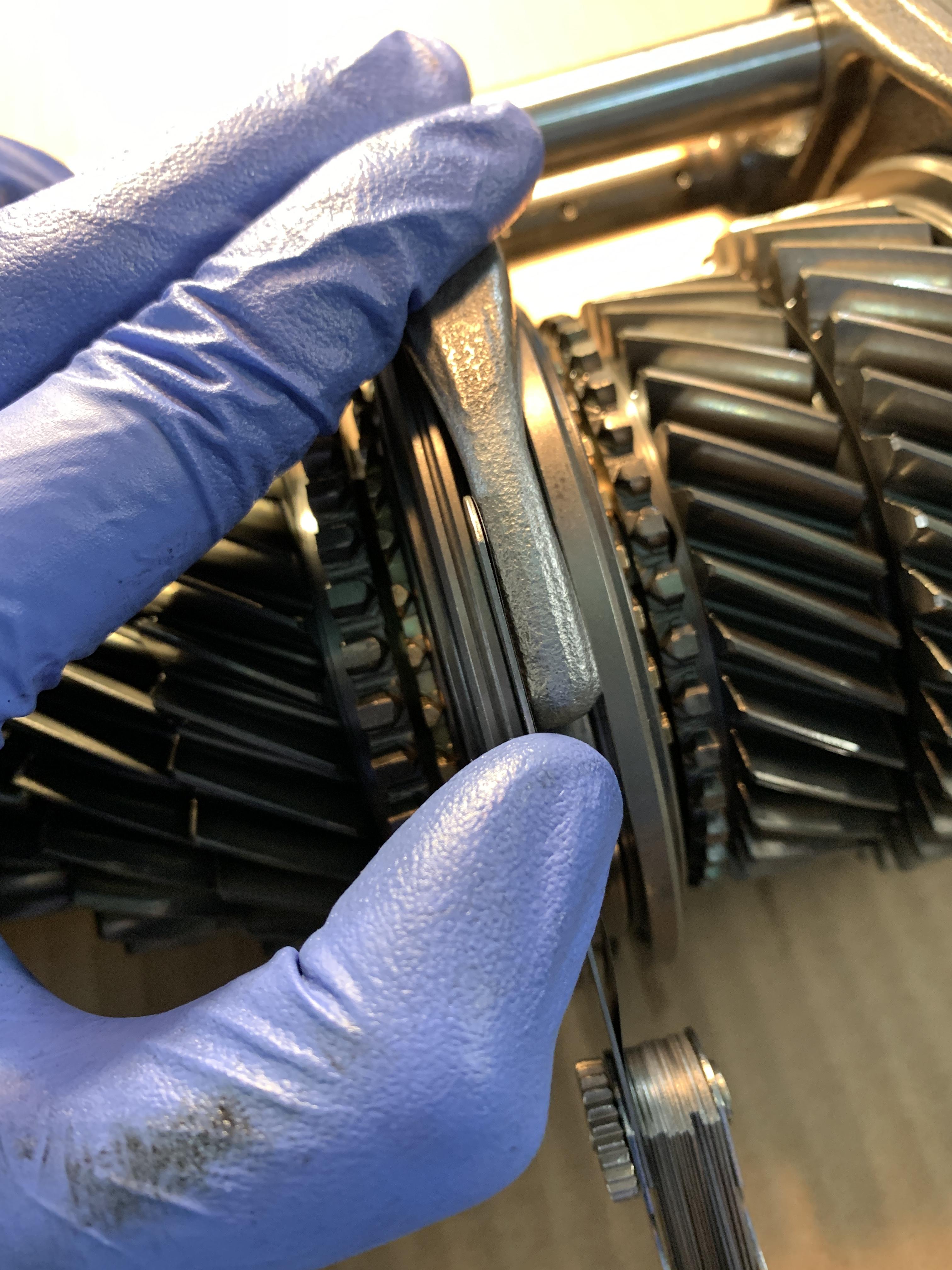

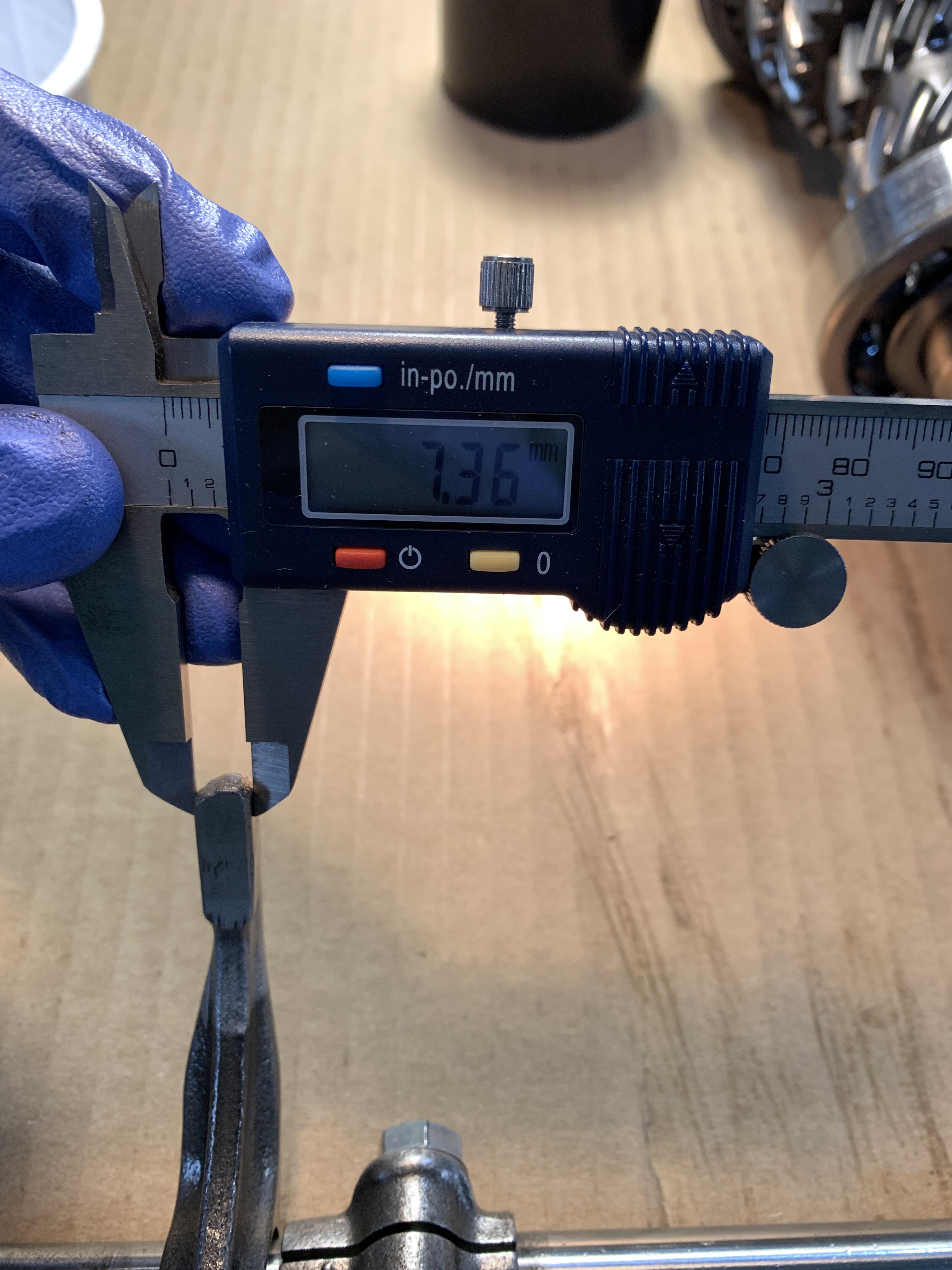

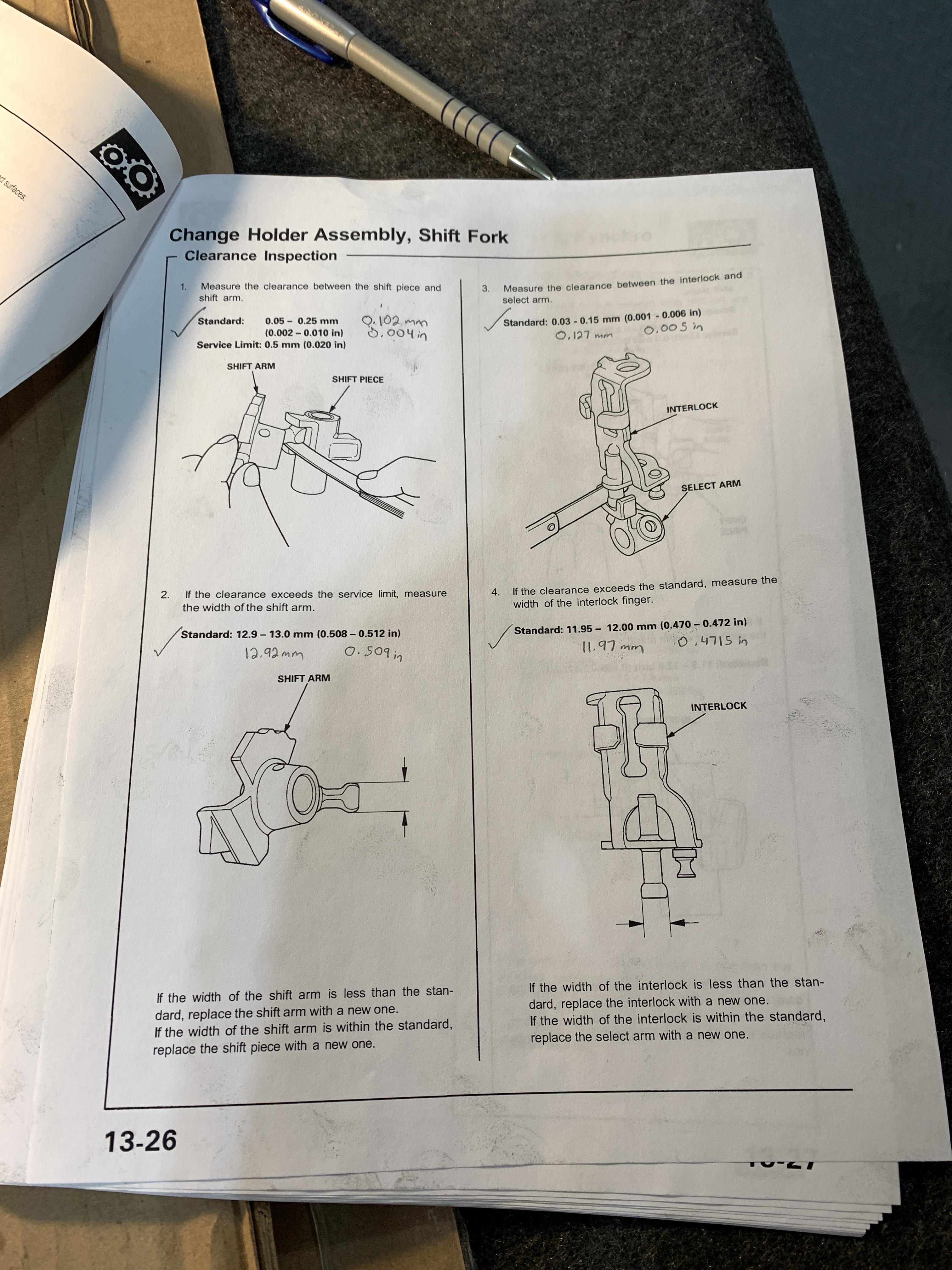

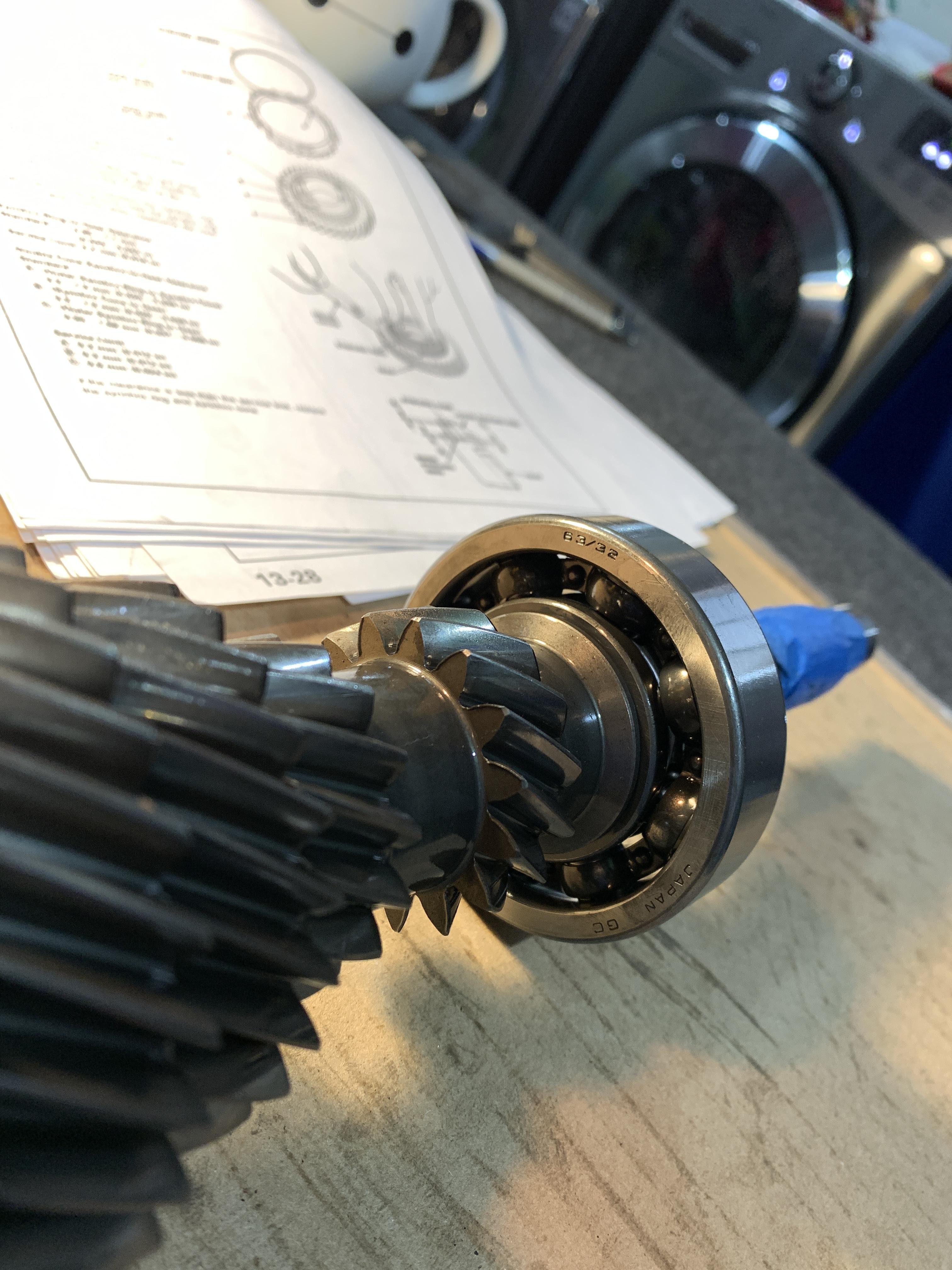

- All the tranny rebuild stuff like bearings as mentioned

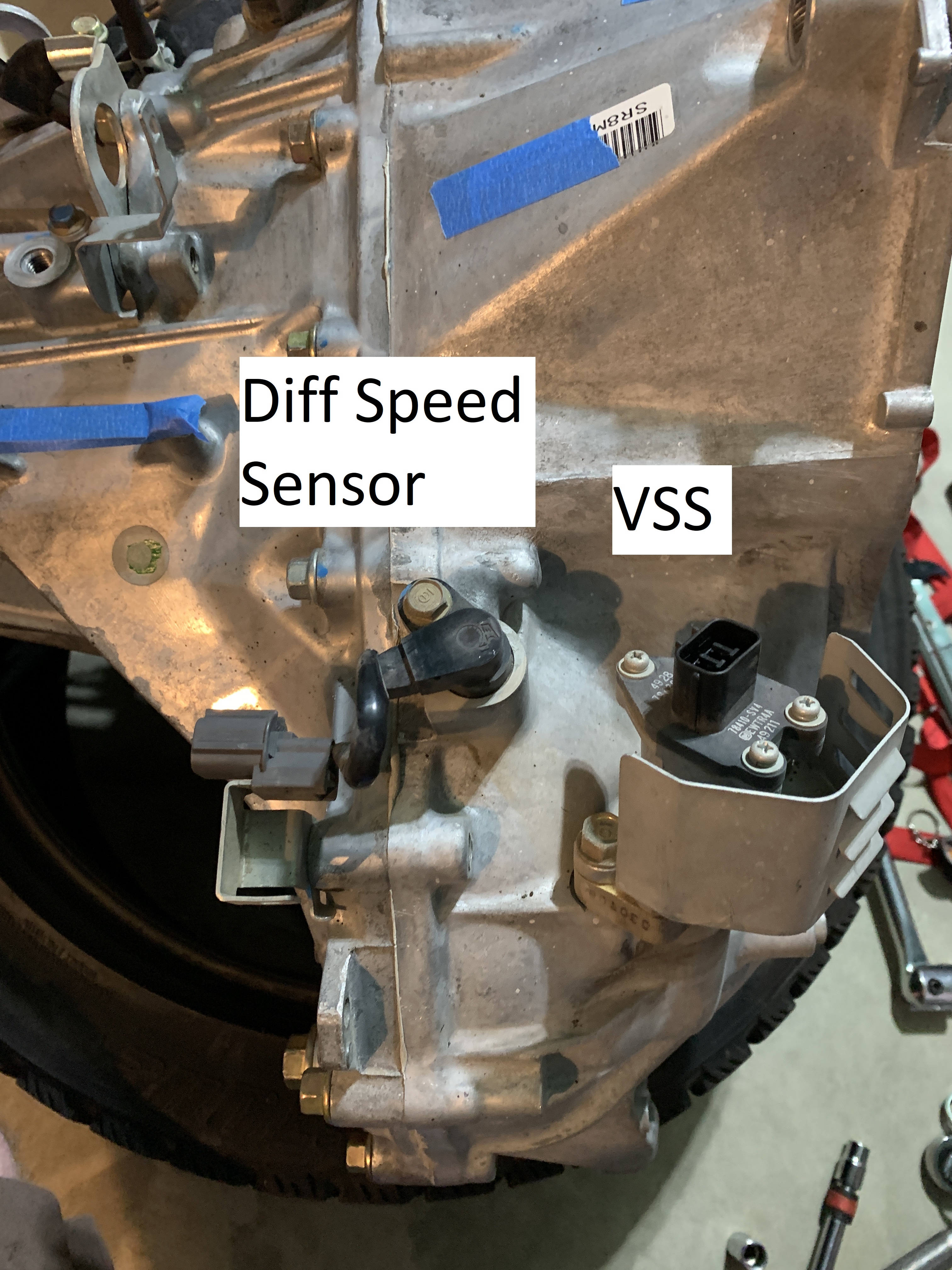

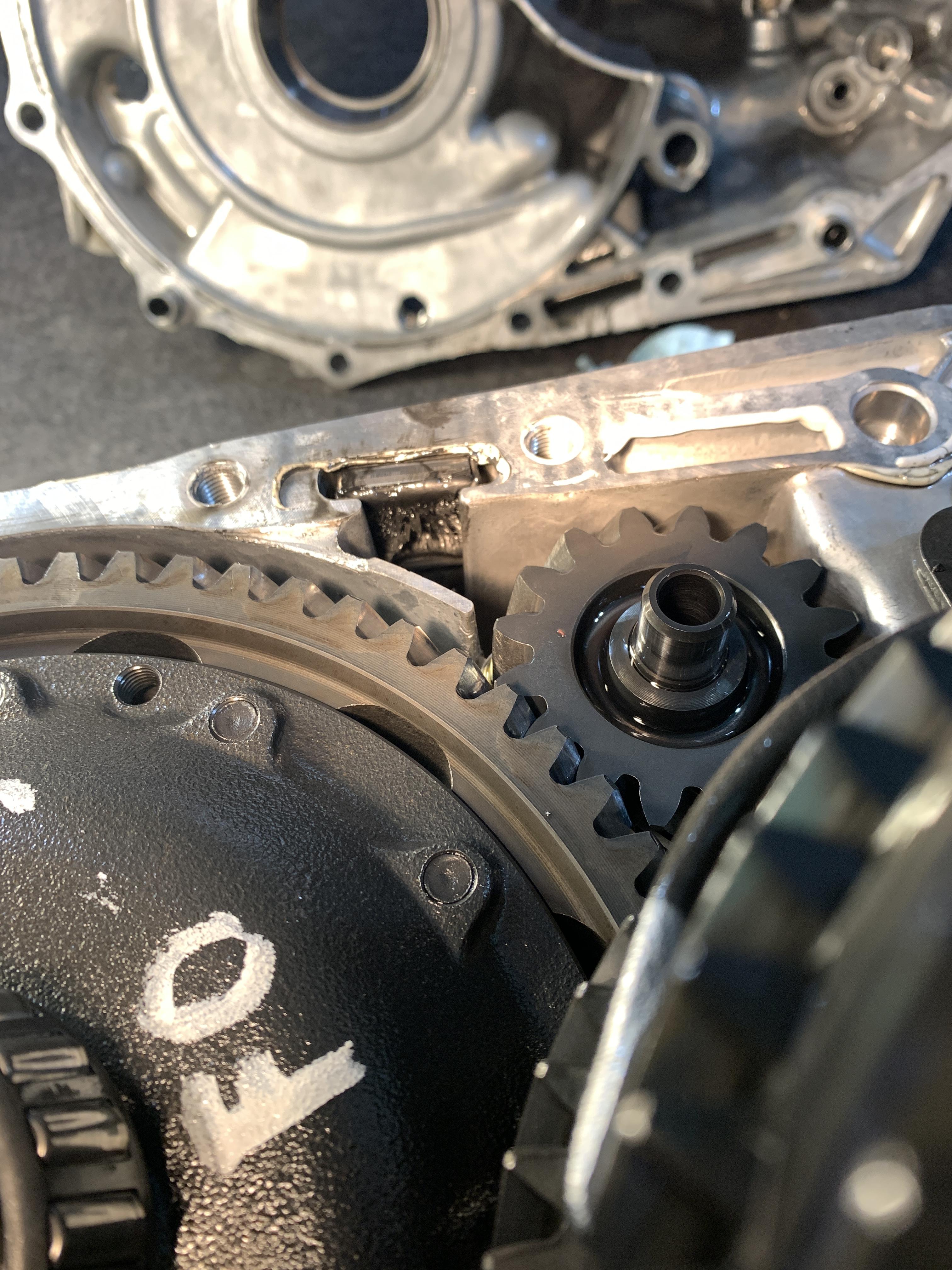

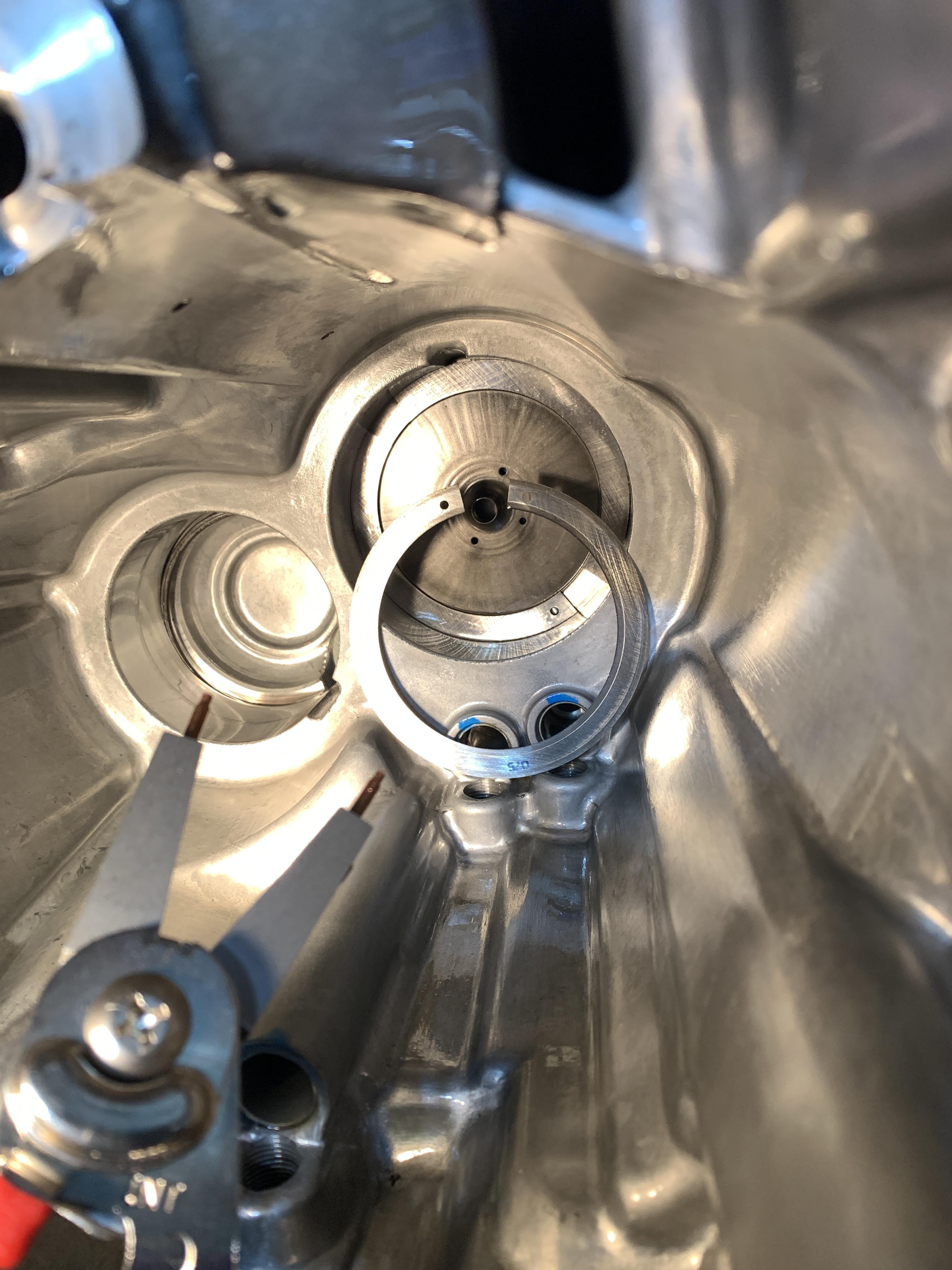

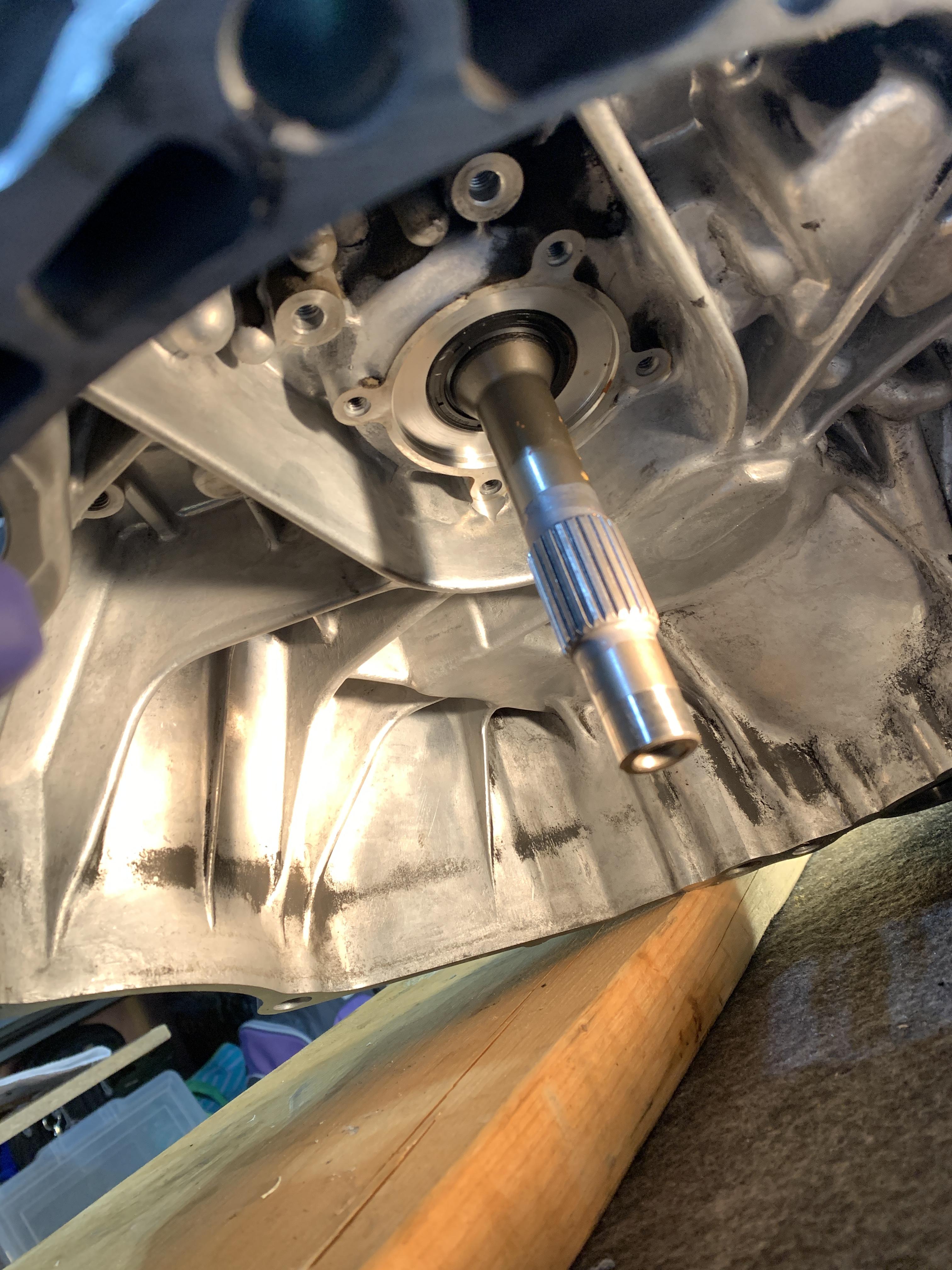

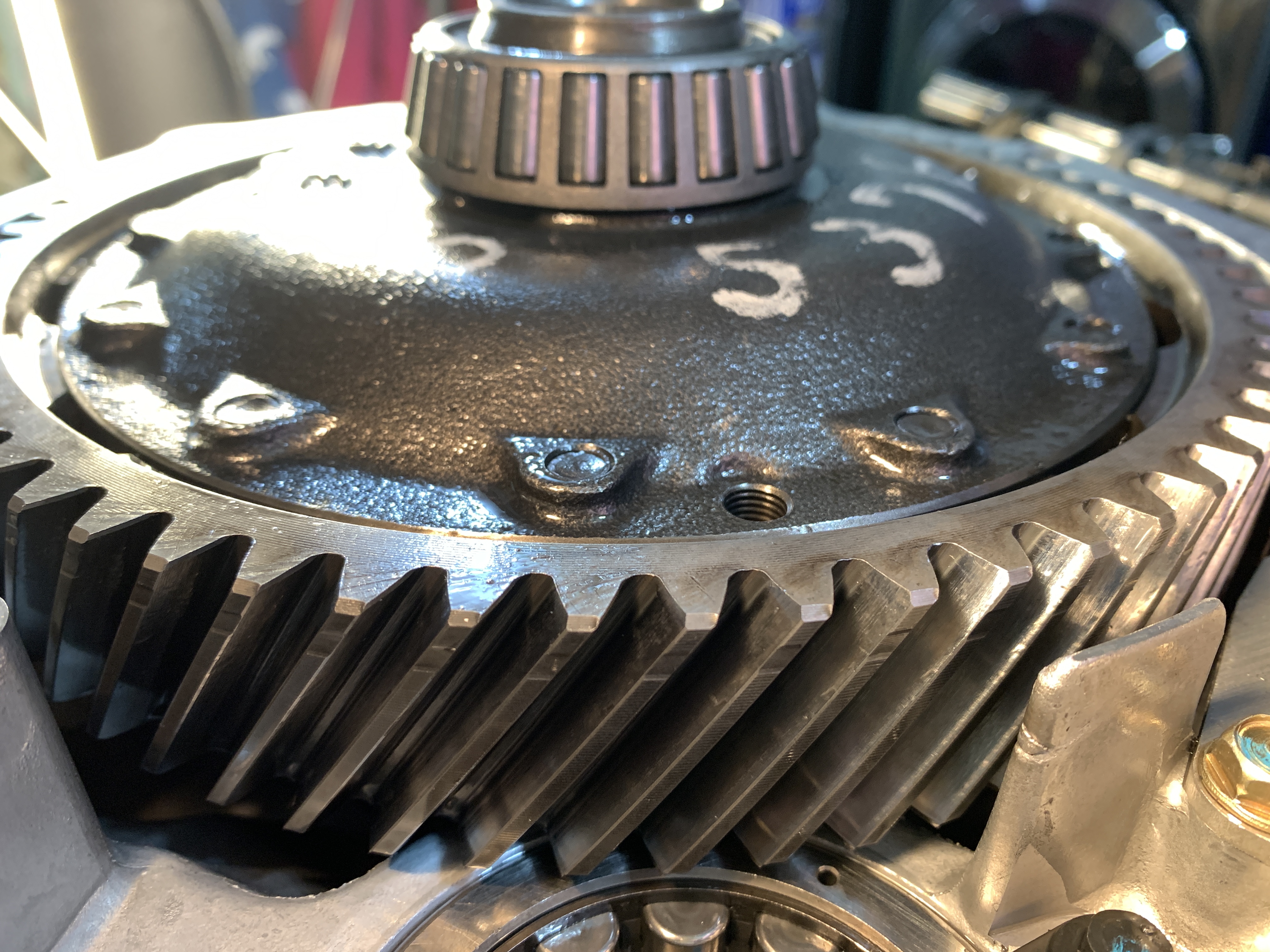

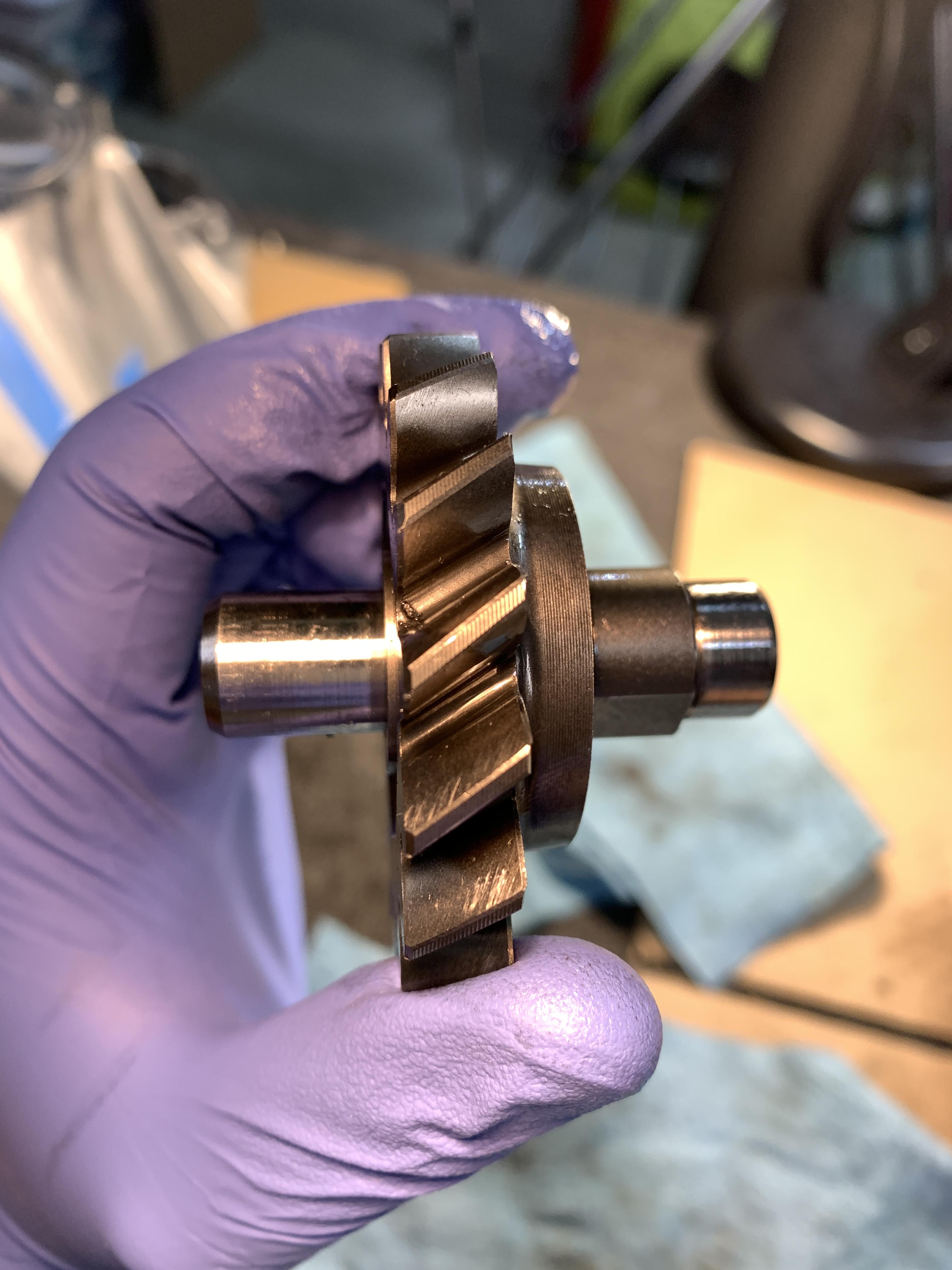

- If this car is a keeper I'd consider swapping the input shaft to a dual spline NSX-R shaft that allows you to use a twin disc clutch which are more readily available in various options. IIRC the dual spline input shaft is backwards compatible with the stock 6spd clutch (double check that though). 4.23 shorter final and pinion gear is also something i'd consider. Again, not sure if these are priorities for you. You have a very late model NSX so perhaps not.

Some parts come to mind.

- Main crank pulley shield

- All the tranny rebuild stuff like bearings as mentioned

- If this car is a keeper I'd consider swapping the input shaft to a dual spline NSX-R shaft that allows you to use a twin disc clutch which are more readily available in various options. IIRC the dual spline input shaft is backwards compatible with the stock 6spd clutch (double check that though). 4.23 shorter final and pinion gear is also something i'd consider. Again, not sure if these are priorities for you. You have a very late model NSX so perhaps not.