Big McLargeHuge said:So what's the big secret here? Everyone says this shaft is a different length, but did you adjust the length somehow to match the M/T version or is it okay just to re-use it without modifications?

drew said:Reusing seems to be the consensus and there isn't any reported issues. In theory it might slam into the diff, but in practice there is probably enough tolerance for the longer shaft of the AT.

In effect, the AT drive shaft is 5mm longer and the AT intermediate shaft is 7-10mm longer....why Honda couldn't specify the the AT (or MT) to be in same relative position as each other is strange.

FYI: I find there is lot of "float" of the axle within the CV joints...so I'm not really concerned.

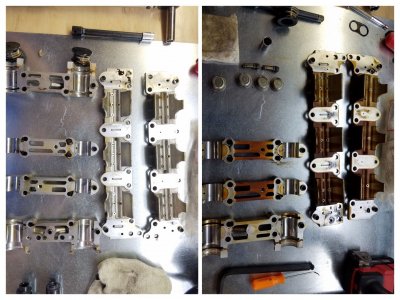

The actual metal shaft is different, but as [MENTION=5430]drew[/MENTION] mentions, it's not that much longer. The shaft length "adjustment" described in the shop manual is for the purpose of removing the correct amount of air from the boots. Basically you affix the large bands, compress the shaft to the specified length to push out the air, and then affix the small bands. Kaz does it little smarter- he fixes both bands, but puts a small straw under the small bands. He then compresses the shaft (blowing the air out of the straw) and pulls out the straws. That's how I'm doing it.

There is a lot of "slop" in the joints, which is why most people re-use the AT shaft in the MT. But, you are taking up some of the slack to make the length fit, so it is possible you are losing some suspension movement. Also, Kaz notes that you may struggle to release the shaft during service because the extra length makes it harder to swing the axle end away from the transmission case. I wanted to avoid these two issues, so I bought a used shaft out of a 1999 MT and will refurbish it.

That looks real good to me, I'd personally re-use it. I'm sure new ones will be discontinued soon if they aren't already, maybe you could hold it in the OEM bag as a collectors item like the tall oil filters but even better

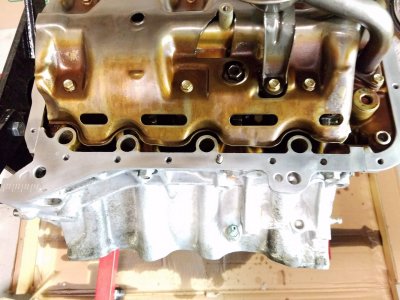

Reuse the existing cooler. It might outlast the vehicle and is that not that difficult to replace. Keep your sealed one, it might be worth a small fortune in the near future.

I'm leaning this way too. Though, I'm keeping the cooler for me, along with other parts. Once this project is complete, I will start stockpiling parts for the life of the car (TB/WP kit, CV boots, door seals, brake pistons, etc.). I have it on fairly good authority that Honda will continue parts support for the Gen1 NSX through 2040. But after that, almost all of it will stop. I want to make sure I have the critical OEM parts that will require service in 10-20 years.