Dang it's been a while.

I haven't really done anything too interesting recently but I didn't realize how long it'd been since I'd posted here.

[MENTION=20915]RYU[/MENTION] I don't remember what the diameter of the throttles is off the top of my head, that project has been placed on the back burner for the time being, I discovered that I don't have a viable method of chopping up the intake manifold and dropping $2k on ITB manifolds from AS isn't something I want to do when I have so many other things I want to buy at the moment. I will also need to write and test my own compensation subroutines for things like you mentioned such as MAP, atmospheric pressure, and road speed if I want to use the factory ECU. In theory it's simple to write that sort of code but if you add too many computations for each injection event the ECU won't be able to keep up at high RPM. Realistically, if I go ITB I'll probably end up using a standalone once the stock setup proves inadequate for the application. I'll PM you about the door locks.

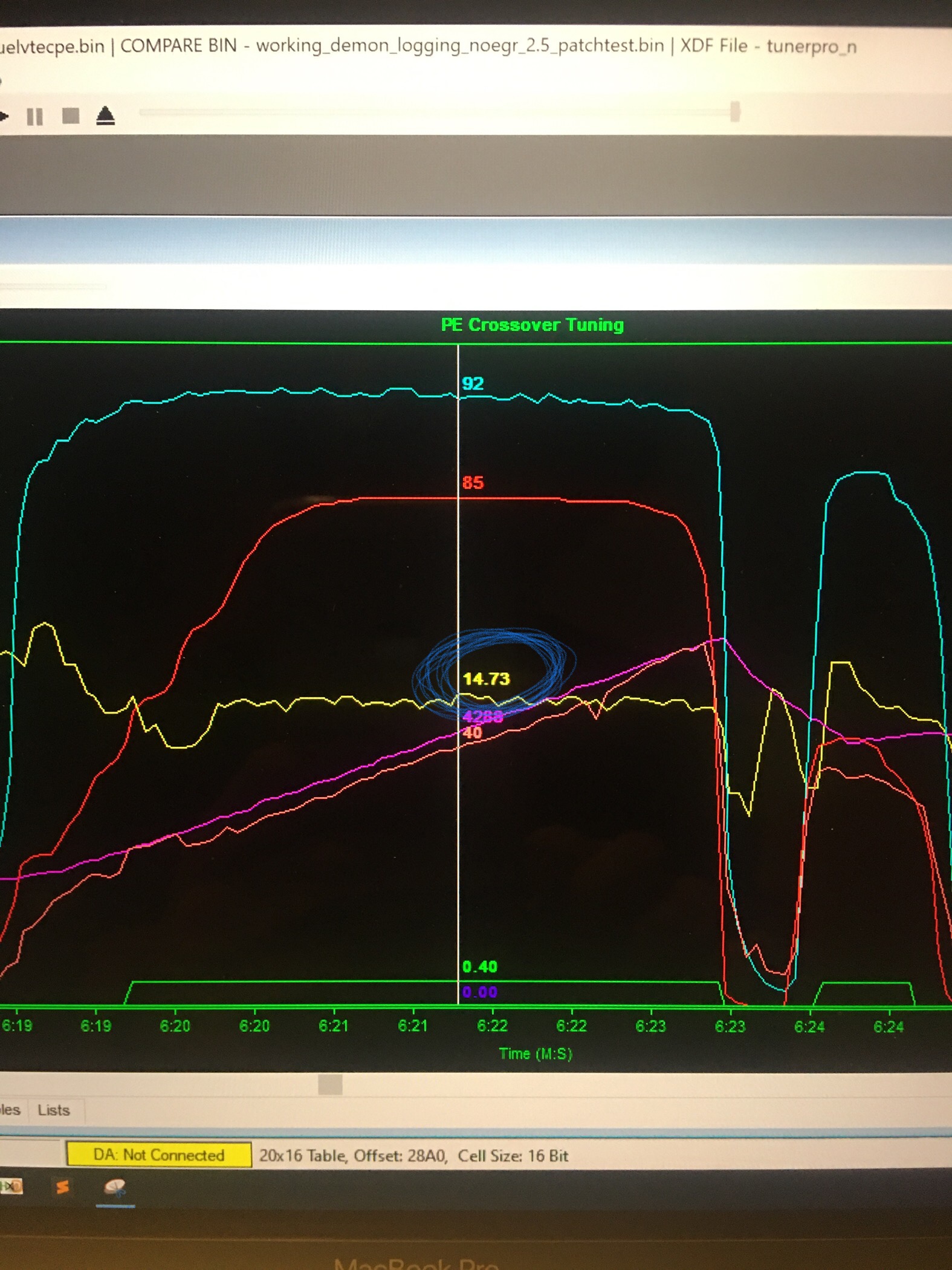

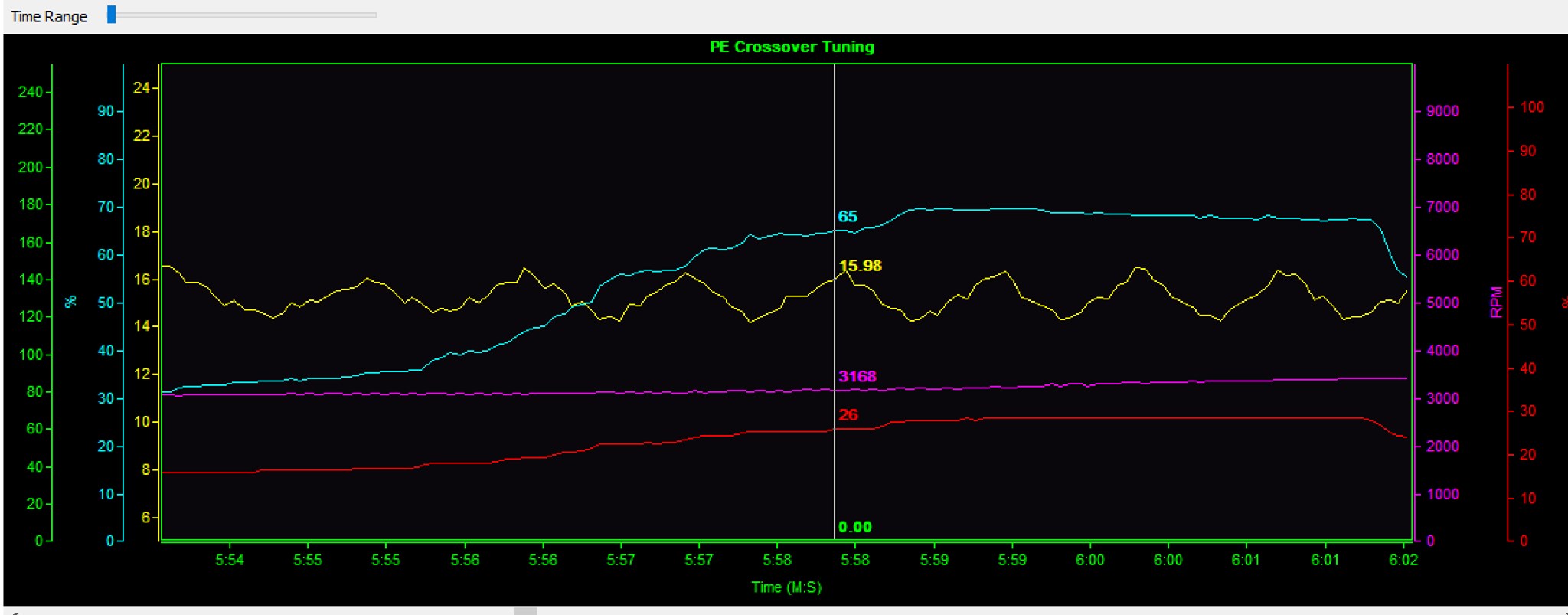

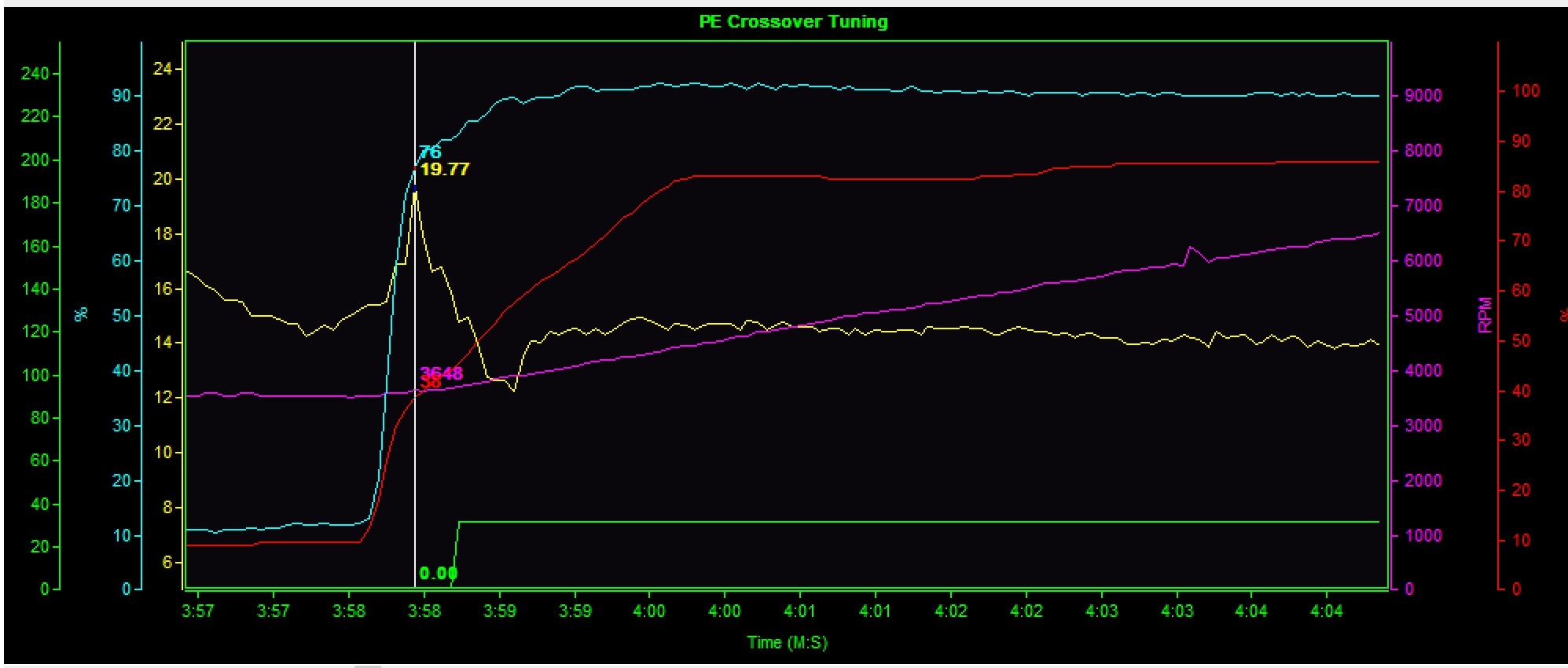

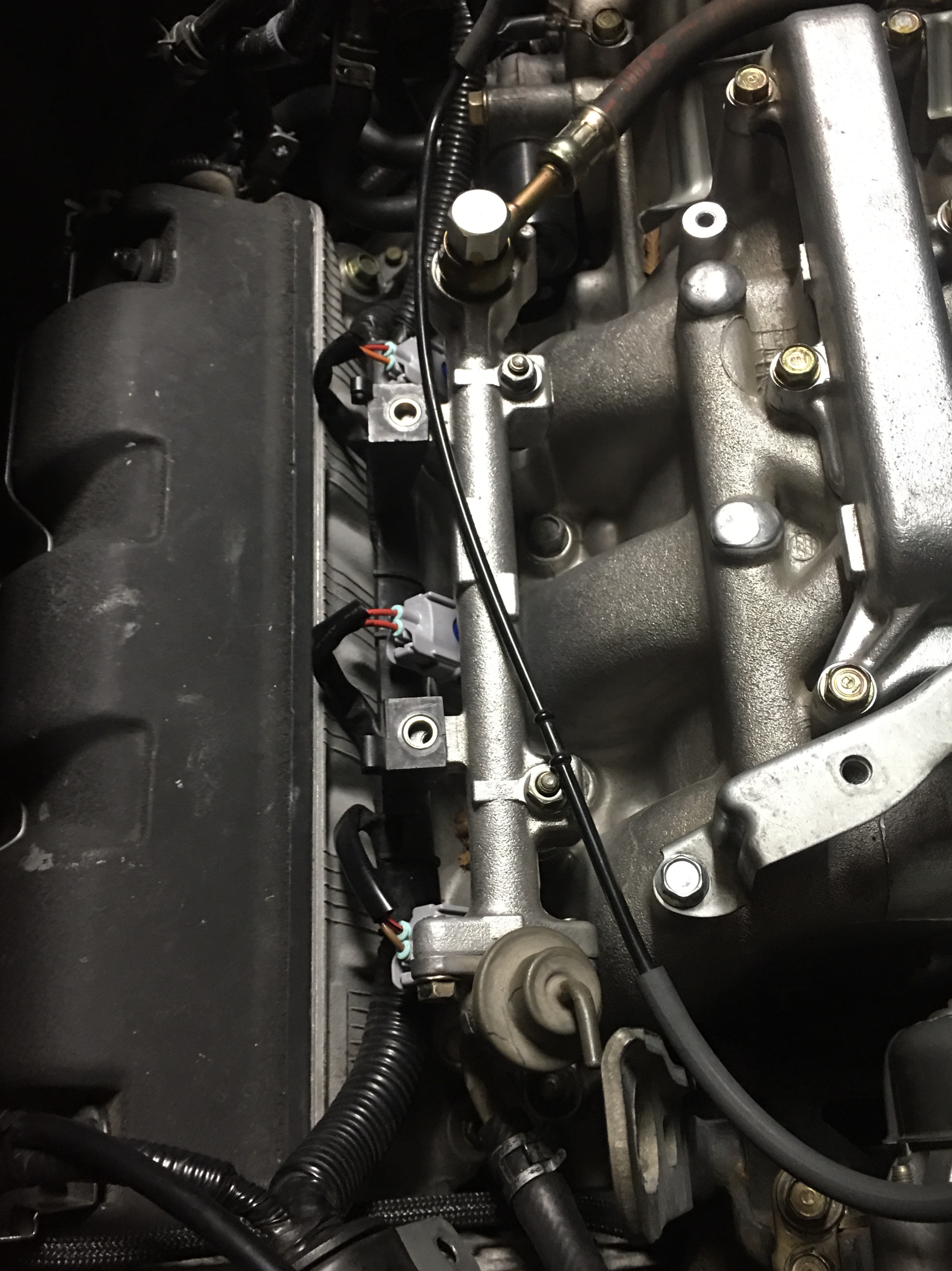

I converted to RDX injectors and have been too lazy to tune it myself and have instead just been running the crappy off the shelf tune offered by a certain shop that I won't name here because I got the tune for free. The car drives noticeably worse with that tune than the stock injector/tune setup but AFRs are safe so it's not a huge priority lol.

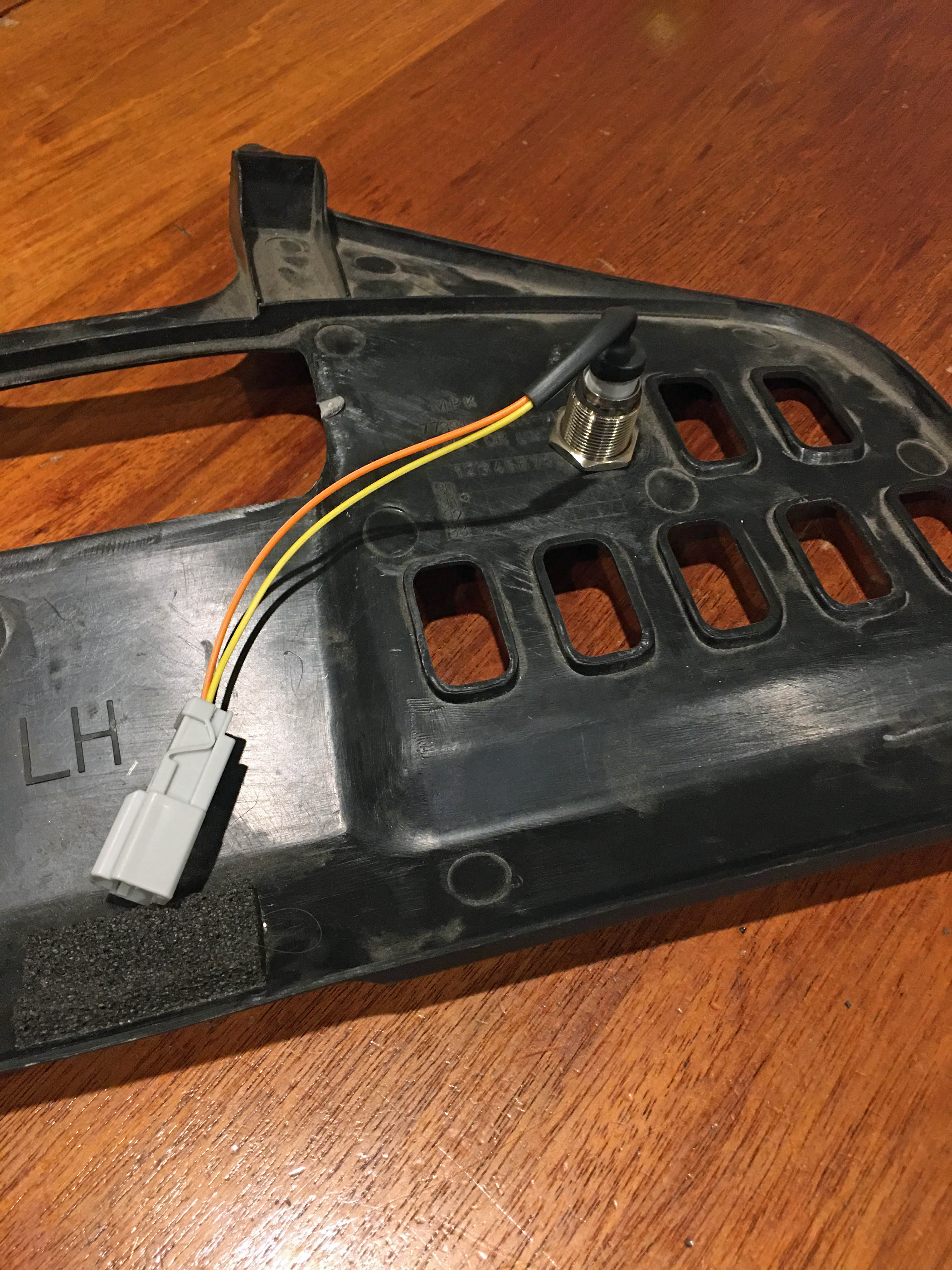

I sourced RDX injector plugs, cut the stock ones off, and then crimped the RDX pins on so its as close to a factory install as you can get.

I was also having some really weird idle issues in cooler weather and I tracked it down to the fast idle thermo valve. The plastic donut thing had backed out on its threads enough to where the car would idle anywhere from 1500-2500rpm in weather under about 75F and idle just fine when warmer, but since cleaning and tightening it's idled perfectly.

I got the block back from the most recent machinist and he fucked it up too. Honed out of round by more than 0.0010" in 2 cylinders. He said run it, everyone else including Wiseco said hell no, so he gave me the runaround and I cut my losses and I ended up selling the block to a guy who bored it out to 93.5mm and was trying to make 700hp on it, then bought a used block from the classifieds here and sent it off to Darton for MID sleeves, ARP main studs, head bolt timeserts, and a line hone, and as far as I know it's just been sitting for the past 6-8 months since they're so backed up.

I sent the heads off to Bad Guys Worldwide in CA for supertech bronze guides, supertech springs, +1mm intake valves, and some port work. He's had them for about 6 months now, and is also crazy busy. He wanted to vapor blast and flow test before and after upsized valves and porting and such so I'm happy to let him take all the time he needs, especially since no one has really done any sort of development on C30 heads since the 90s and he seemed excited to do it and has all the equipment in house. No one has even posted flow numbers for these heads that I'm aware of so if he can get good improvements in flow with porting it could open up another option for other people in the future.

I looked into having Web Cams regrind or hard weld my cams and after seeing the specs on their regrind (barely any additional lift) and the hard weld (cost as much as Toda cams) I decided that was a waste of time and money. So I'm running stock cams for now and will go to either Toda A or Comptech cams down the road.

I've given up hope of any machining getting done any time soon.

I also placed an order for a set of Volk ZE40s in anodized bronze in January. 17x8.5 in the front and 18x10 in the rear, 275s should look pretty nice in the rear compared to the measily stock 245s. Depending on the fitment I might get BC coilovers or maybe swift lowering springs if I can find them. I've wanted these wheels pretty much since I got the car so the 6-8 month wait is a bit disappointing but I suppose that will just make it sweeter when they finally arrive lol.

At least the center caps showed up quickly.

I've also been working on cobbling together a budget BBK using Porsche 996 911 calipers from Ebay. They have the same pistons sizes as the stock NSX calipers so can be used without ruining the bias like some guys used to do with the RL calipers, then just NA2 calipers and rotors in the rear. I don't like the silly little parking brake calipers people run with BBKs and that would also ruin the budget nature of this so I'm not going to mess with getting 4 pots in the rear, and for my naturally aspirated ambitions this should work just fine. For front rotors, I dug through the Raybestos parametric rotor search and found that late model Nissan Rogue 320x28 rotors will fit pretty much perfectly once the center bore is widened to NSX spec - the lug pattern is the same just the center bore is a few mm too small, and its a simple/cheap job for a machine shop to bore it out a bit more - so that gives me a huge number of very cheap rotor options to choose from that will be easily accessible for the next few decades. I bought the cheapest one on Rockauto for mock up purposes and it fits without even removing the heat shield and also moves the caliper inboard a bit allowing more clearance between the caliper and wheel.

As far as actually fitting these calipers to the NSX, the NSX has the calipers on the front side of the knuckle and the Porsche Boxster/911 that these calipers came from have it on the rear, the solution is simple enough just turn the calipers upside down and move the crossover pipe to match so you keep the correct big little piston orientation. However, these calipers have a small protrusion in the casting to offer a bit of protection for the crossover pipe and that is no longer in front of the pipe in this configuration, so I'm chopping it off to make the calipers perfectly symmetric.

Filed and blasted, ready for powder.

I got lucky and scored a set of reman NA2 calipers on Rockauto so I pulled them apart immediately (after learning my lesson with remans on the Integra) and found one of the pistons completely trashed. It's about par for the course for a reman and they were cheap enough that I'd rather just buy new pistons than deal with sending it back and trying to get another one, they rarely come in stock and most guys want $500 each for used ones, and these were less than that for the pair. They didn't properly mask the piston before media blasting it so the surface is rough, and it also looks like it was dropped on concrete or something based on all the little knicks. New ones are about $30 so not bad so I just added them to my pending Amayama order.

The NSX was on daily duty and living outside when Texas froze over. Shortly after taking this picture I reorganized my GFs garage so I could fit my car in it, which turned out to be a good idea as it got down to 7F a day or so later.

I decided to change up the steering wheel too and swapped out the Momo Tuner for a Momo Zagato/NSX Type S wheel. I ordered a black H horn button from Amayama to replace the red one since I'm working on removing all of the red accents from my interior for a black/titanium grey color scheme.

Post wash.

But anyways, since the spacers required extended studs in the front, I'll have to replace the studs again for the Volk wheels, so I'm going to try the extended lugs and open ended nuts look for a while. I'm going with ARP studs and titanium lug nuts which I think should look pretty good.

I dremeled the brake heat shields to make them removable with the hubs on the car for ease of future service, then cleaned them. I had to clay bar them to get all the stuck crap off but they came out very nice.

Wheel on, mocking up the NA2 calipers. The NA2 caliper pistons are much larger, moving the brake bias rearwards, and the rotors are 303mm instead of 280mm. I had to have the rear tires replaced when I found out how long the wait for the Rays wheels is so I bought some cheap PS31 tires to hold me over, the guy who installed them didn't bother with getting the rotation right and I don't care enough to take it back.

Spacers gone, wheels hellasunk, and reattached with titanium lug nuts for the bling. These lug nuts are taper seat for aftermarket wheels so I got some adapter rings to make them work with the stock ball seat wheels for the time being.

Some more engine parts showed up as well. After a discussion with my machinist we decided to go with Supertech valves instead of OEM, and diamond-like carbon coated wrist pins came back from Calico coatings. This is a relatively inexpensive service I had performed on the wrist pins that came with my pistons and is probably not necessary but just extra insurance, aftermarket rods don't have oil squirters so there's less lubrication on the wrist pin.

And here's a bit of whats planned for later on down the road, I'm planning on converting to all Honda badging and the imola orange H badge matches my caliper accent color pretty well. (please ignore the ugly red crossover pipe, those are getting replaced with new black ones)

Recently I've found that my turn signals aren't cancelling anymore so the next thing will be to figure out whats going on there.