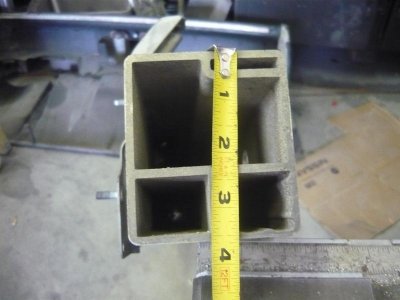

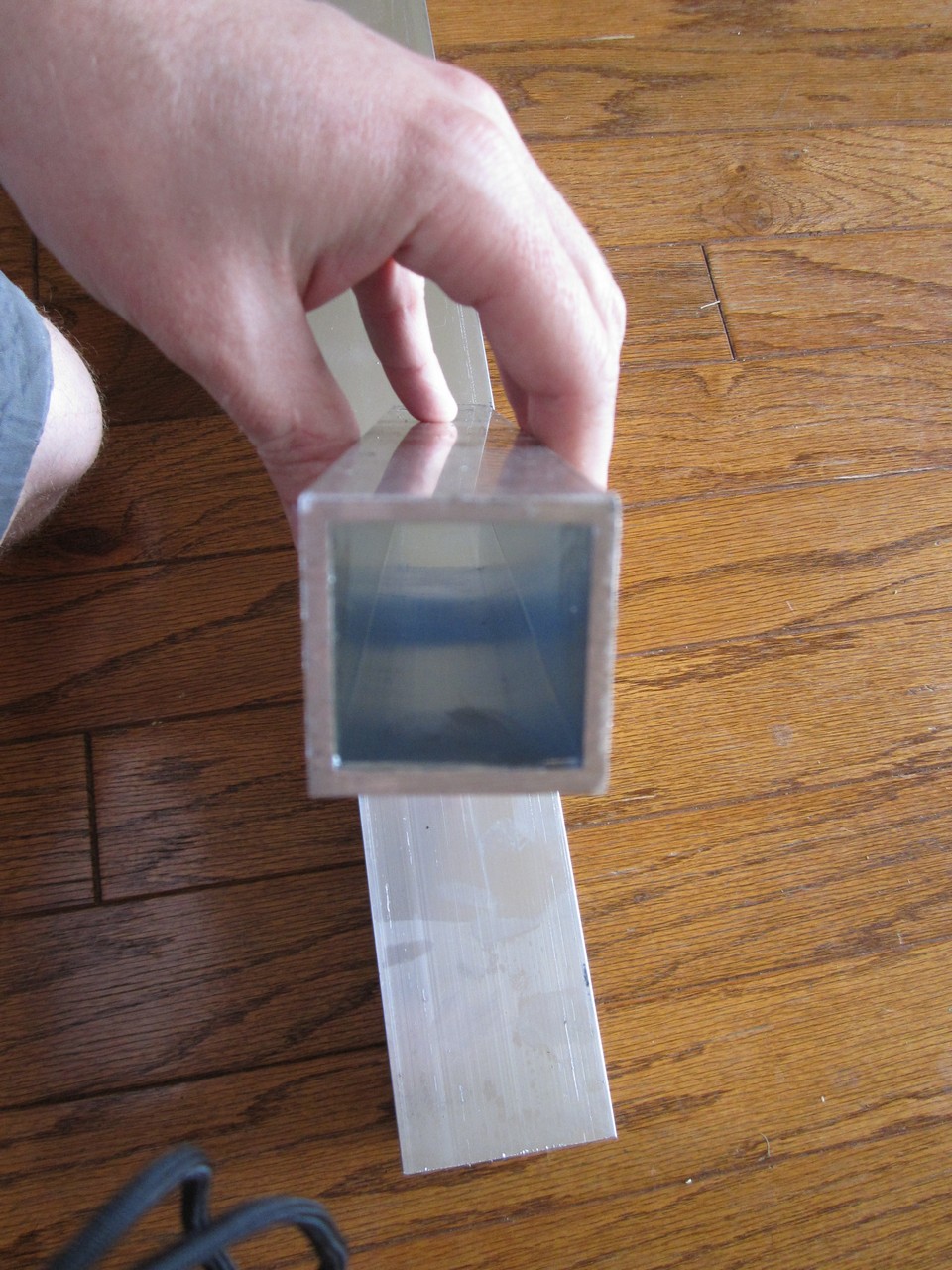

Go to Metalsupermarkets. Pick up one section of 3 inch square tubing .120 wall thickness 56 inches long. Also pick up one section of 1.5 inch square tubing .120 wall thickness 11 inches long.

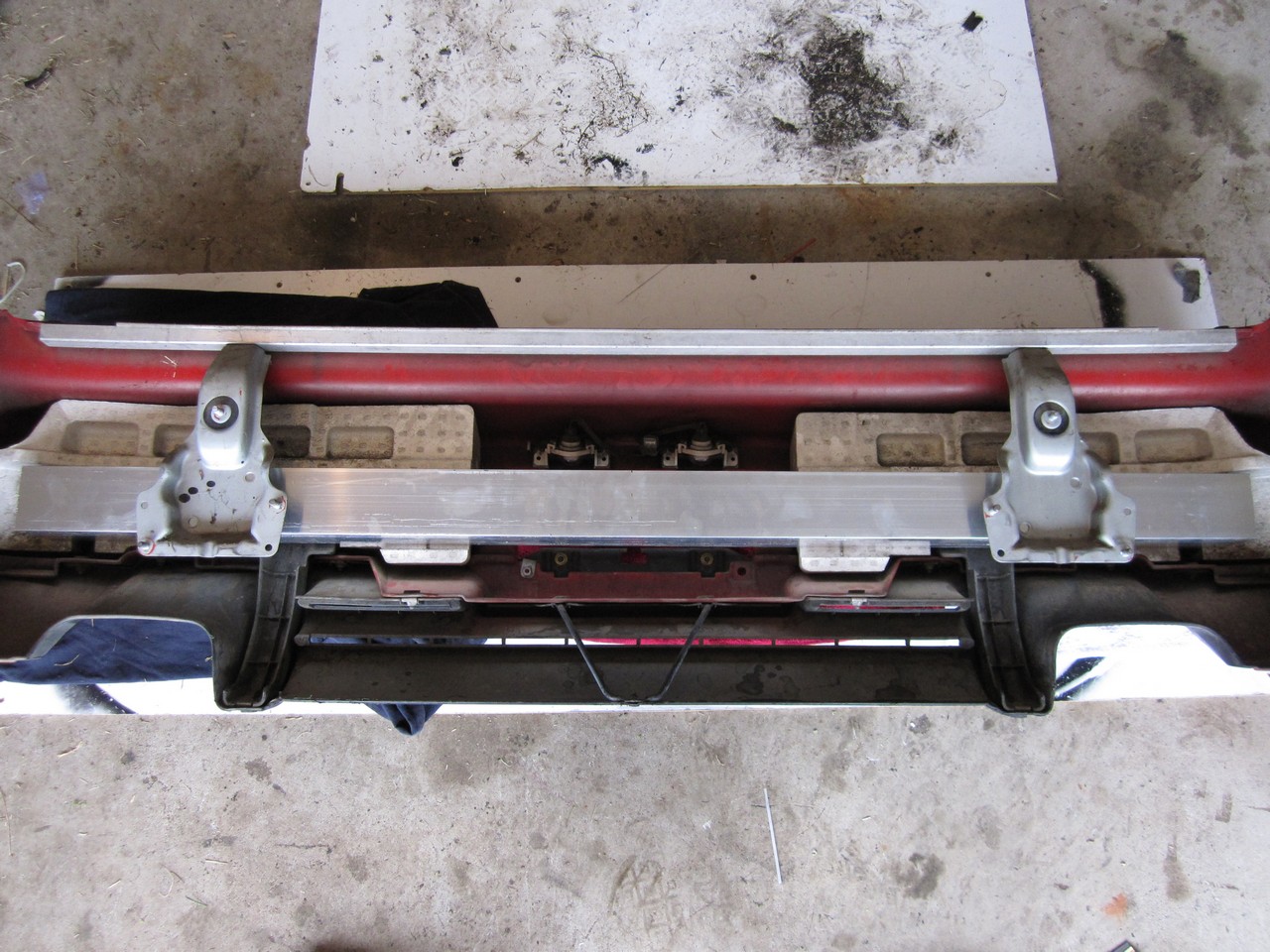

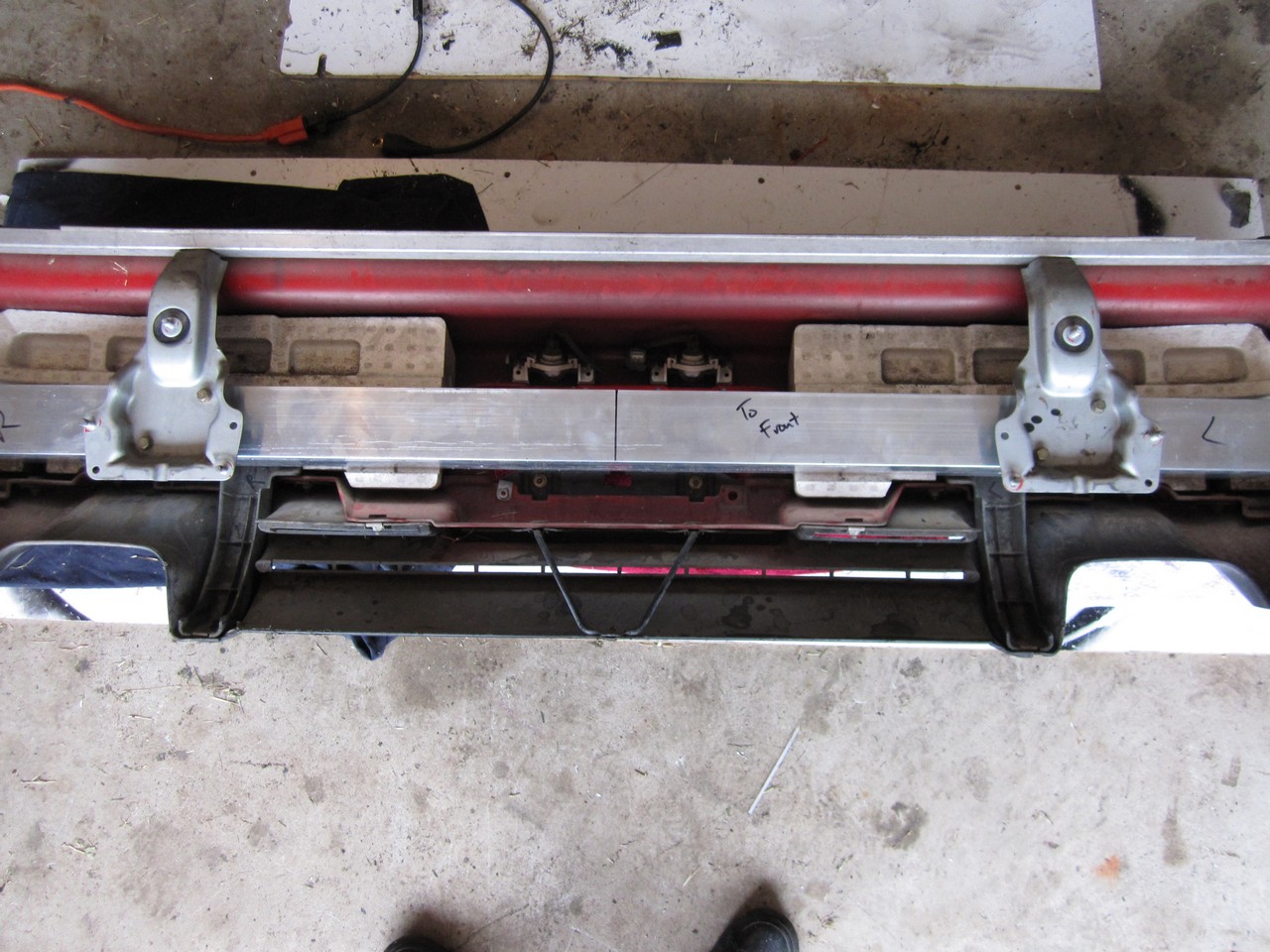

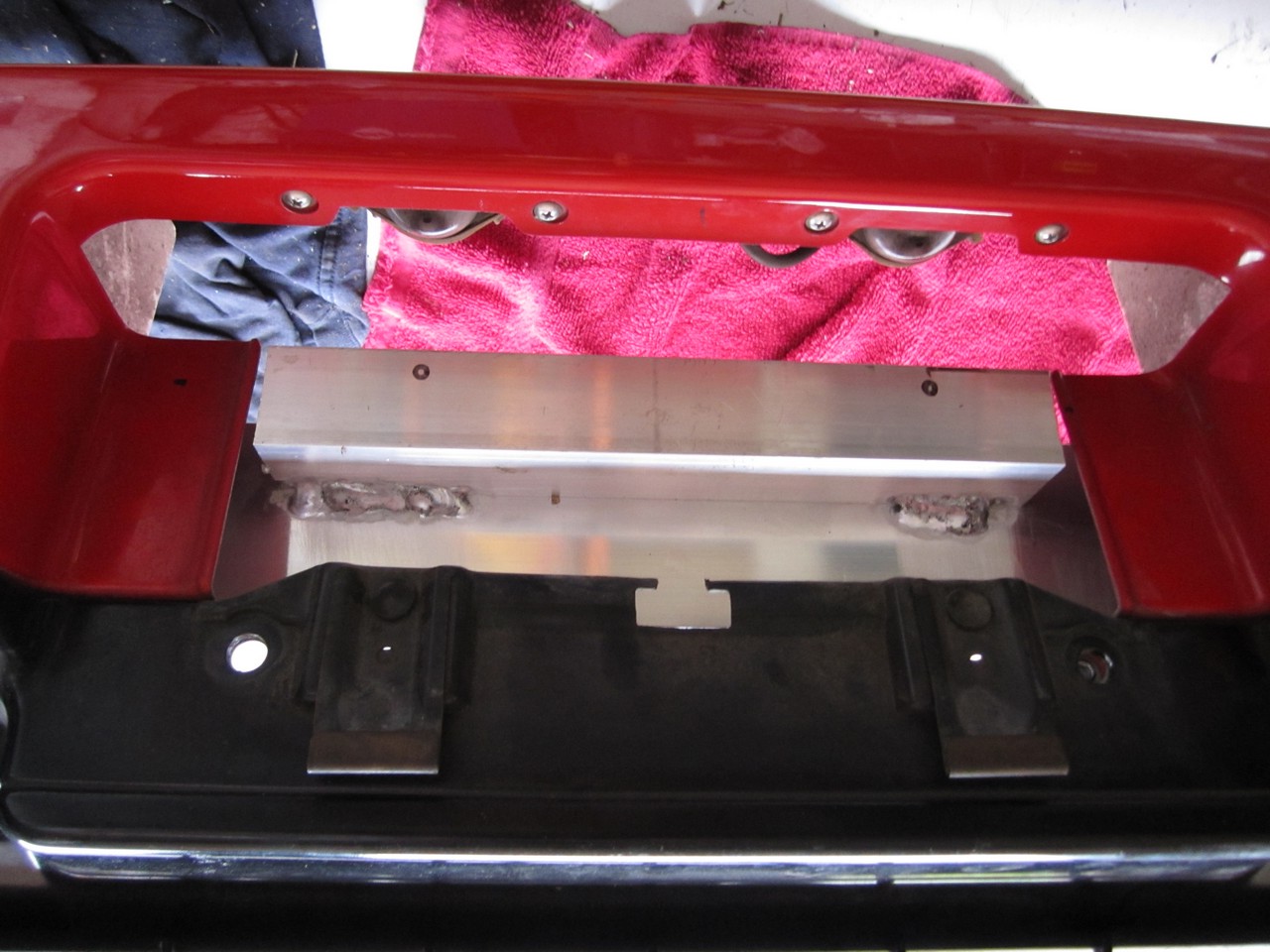

Just going to post images here. It's pretty self explanatory.

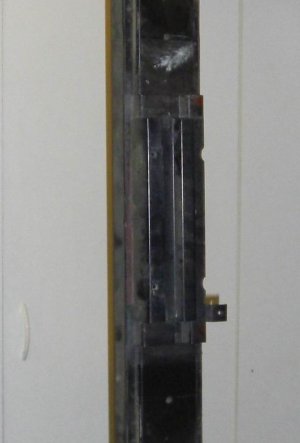

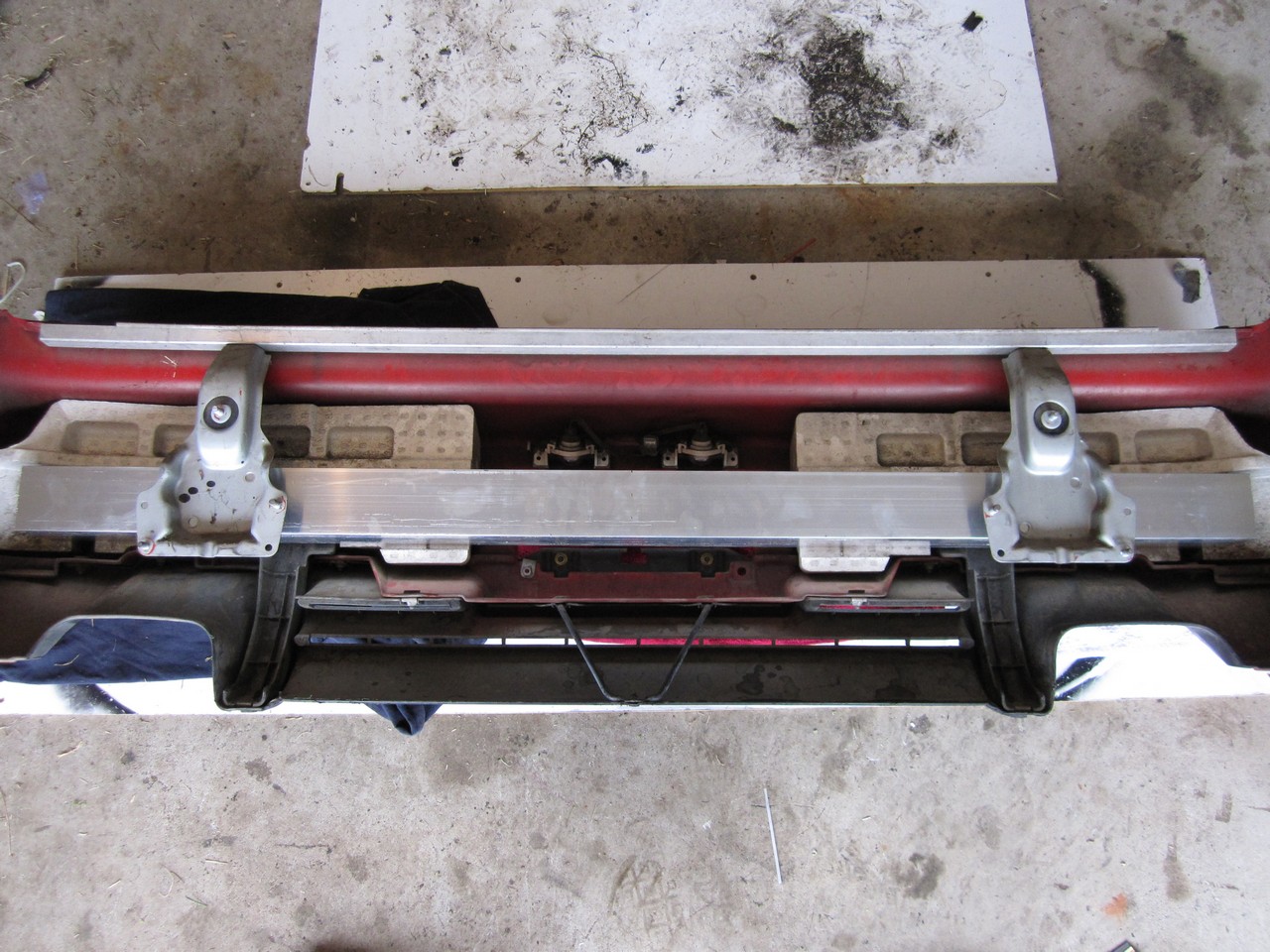

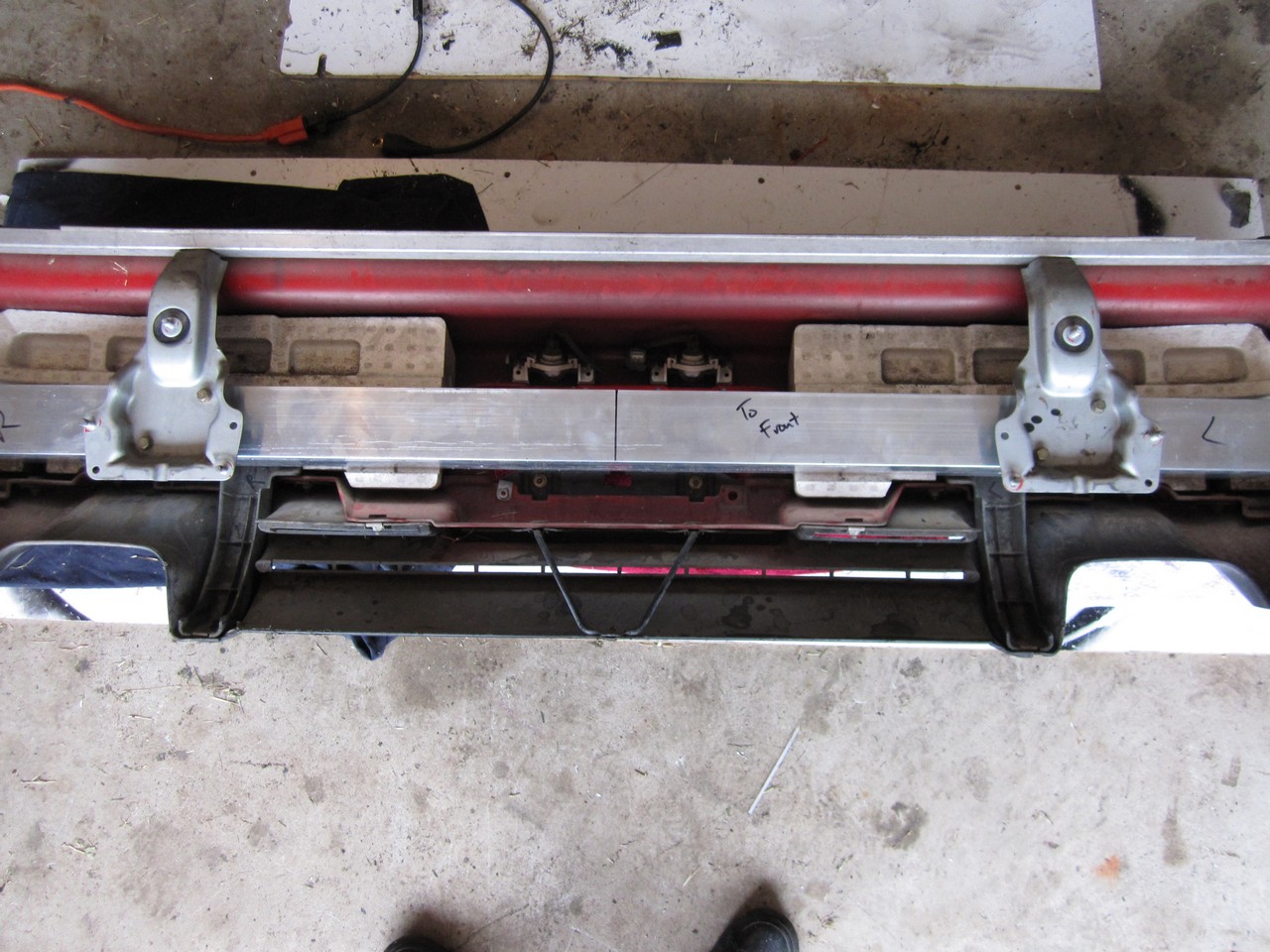

Mark holes to drill.

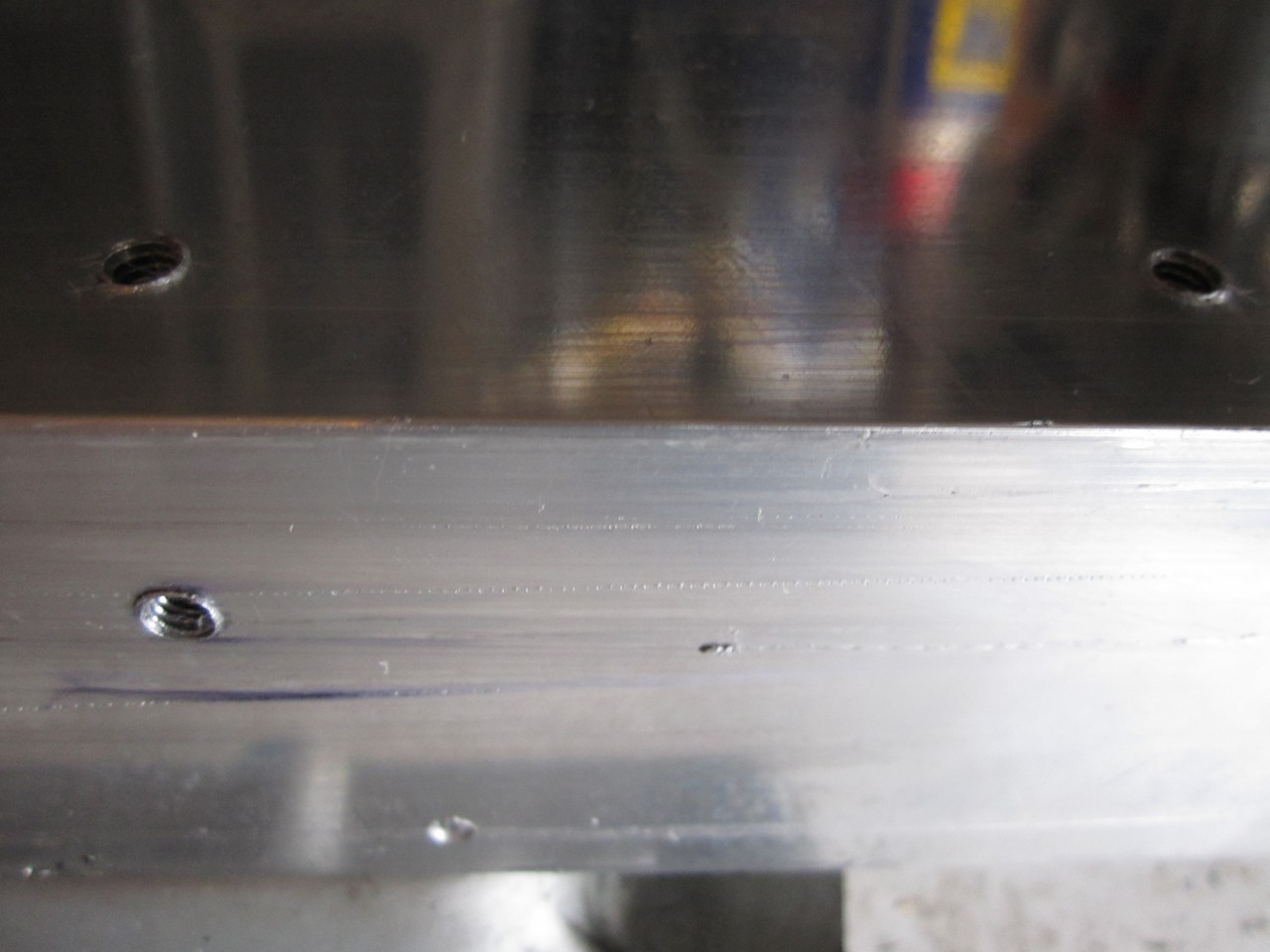

I also put some access holes in the top of the beam so I could put nuts on the bolts easier.

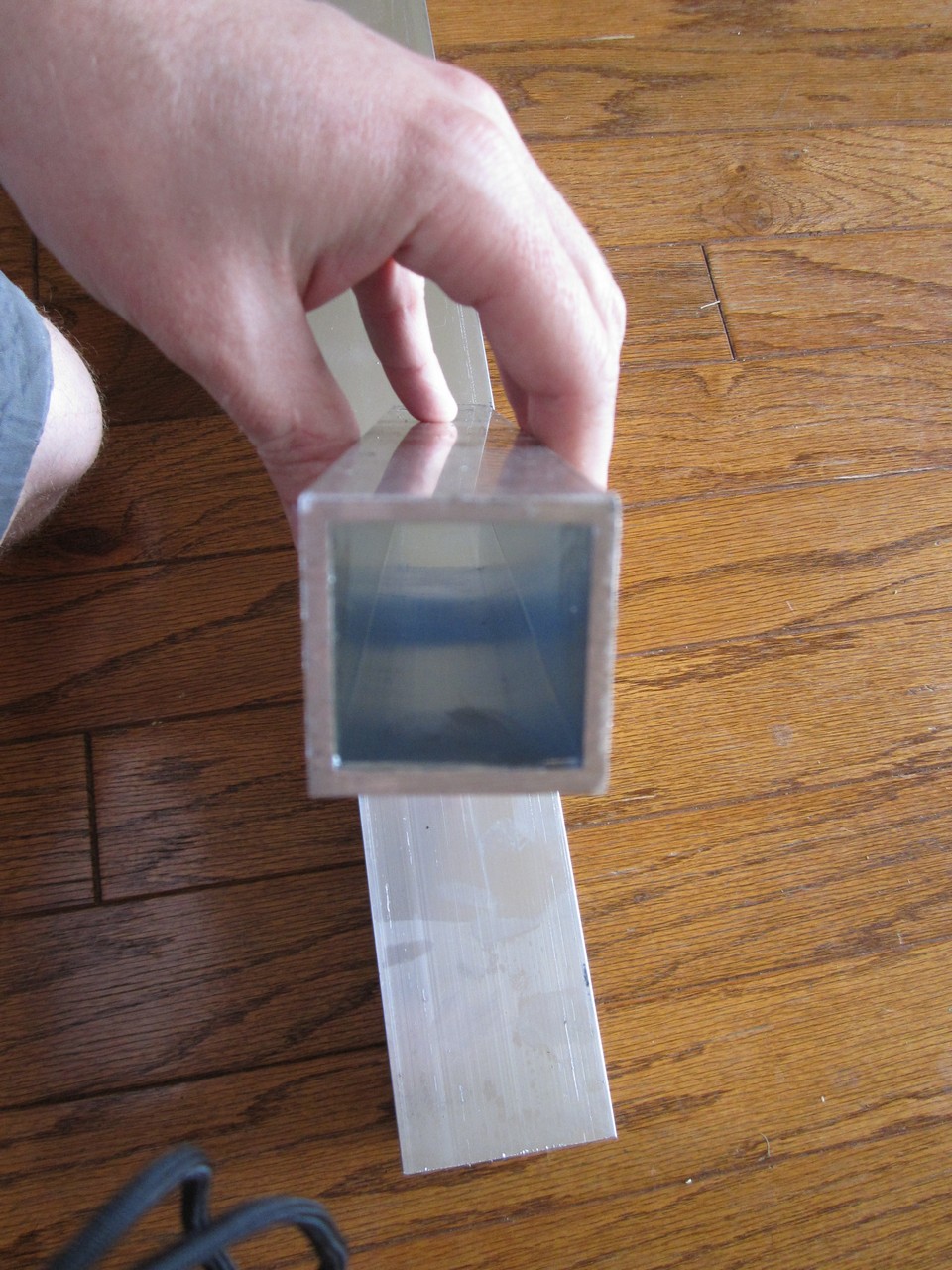

Mark your lower brackets.

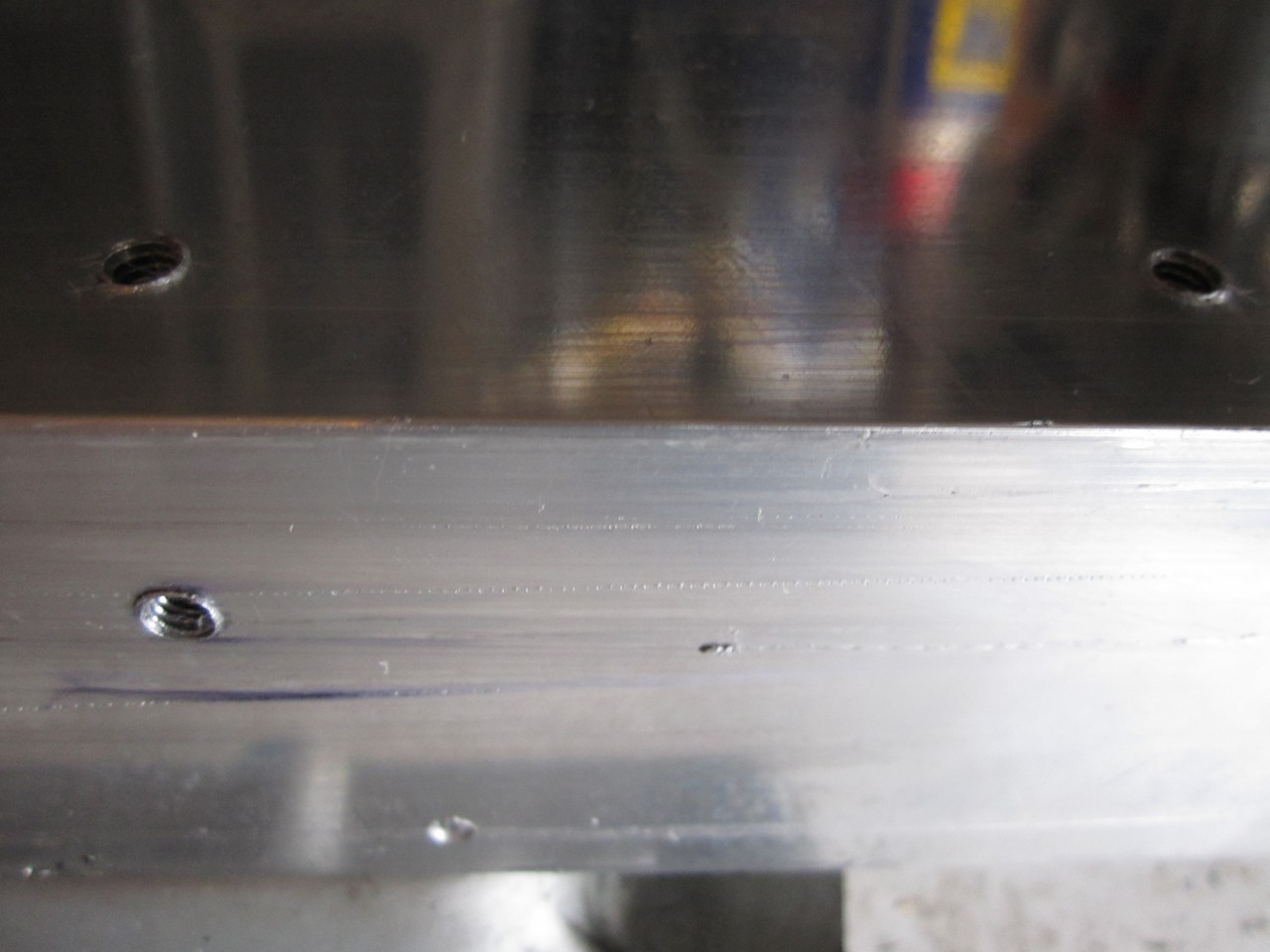

Drill and tap.

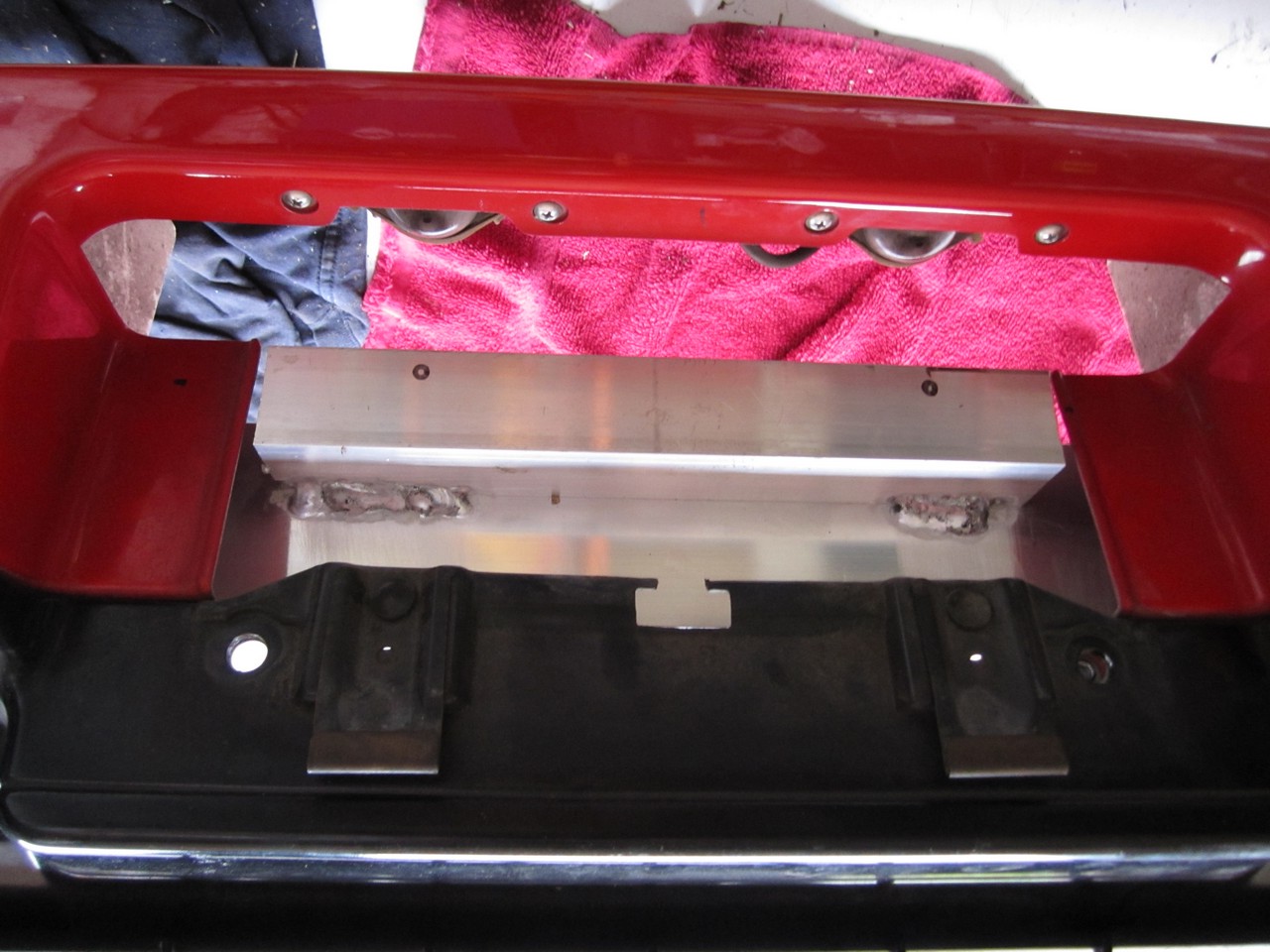

Yeah the welds are terrible. First time TIGing aluminum. Welds on the backside look better. You can bolt the 1.5 inch beam on if you don't have a welder. After this you just drill and tap for your license plate bolts.

Total cost was under $60 for the metal and a few hours of time. A little trimming of the foam was required since the aluminum beam is straight instead of curved.

Just going to post images here. It's pretty self explanatory.

Mark holes to drill.

I also put some access holes in the top of the beam so I could put nuts on the bolts easier.

Mark your lower brackets.

Drill and tap.

Yeah the welds are terrible. First time TIGing aluminum. Welds on the backside look better. You can bolt the 1.5 inch beam on if you don't have a welder. After this you just drill and tap for your license plate bolts.

Total cost was under $60 for the metal and a few hours of time. A little trimming of the foam was required since the aluminum beam is straight instead of curved.

Last edited: