Suspension of Disbelief

Another few days spent installing the Fortune 500's I received a few weeks ago, plus some other related while I'm in there projects.

One, new front wheel bearings. I noticed they felt a bit loose during my brake job and ordered some relatively cheap Timken replacements. These are pretty much an exact fit down to the bearing part #'s and finish on the hub studs so I'll definitely be using them for the rears when that happens.

Here's a shot of the FL side before I begin. Classic peeling undercoating and faded fender liners.

Fender liner removed.

Same for the FR side. I was half expecting a horror show underneath but I actually didn't find anything that concerning. One or two loose bolts sitting around and the bottom of the AC condenser has some crushed fins but everything looks fine. Not perfect, but fine.

View of the RL inner fender with the air inlet resonator which will be swapped out soon, probably with the Downforce piece.

RL inner since I thought it would be interesting to show. I think that writing says "side"?

RR towards the front, showing the now useless air inlet to the engine bay fan that was removed. Prime real estate for an oil cooler or something later on.

RR towards rear. There's a weird one-way rubber flapper, maybe for the trunk? Air hole or pressure outlet for when the trunk is closed?

Anyways, back to the front wheel bearings. Axle nut buzzed off easily. Same 36mm nut as the rear axles. The whole assembly is held on to the knuckle by 4 easy to remove bolts.

Bearing removed with the same separators I used on the transmission. Using the shop press would need some sort of special attachment to properly support the hub which I didn't have.

The old bearing inner race also has to be pulled off, which is the hardest part of the job since the gap to pull from is so small. The second race needed some torching to free it up for pulling, maybe an hour or two of work just for the two inner races on either side.

The new bearing assy is easily installed on the hub with a press and an old inner race as a press tool, then bolted back into the car with threadlocked nuts. Would be a 15 min job if the inner race wasn't so hard to remove.

Next is removing the front struts. The bolts are simple to access and remove, the hard part is that the spring forces the end of the strut into the control arm and needs a ton of fiddling and prying to yank the strut out. Doing this over again I would've used spring compressors on the strut in-situ to make the removal much easier.

Obviously these have seen better days. They weren't leaking at all and felt fine, but age has not been kind to their appearance and the plastic covers on the spring.

Strut removed.

Plus another few hours of scraping and brass wire drill-brushing the old undercoating off. I wasn't aiming for a complete stripping down to plain red paint, I figured if the remaining coating was strong enough to withstand my first few attempts then it would be okay to leave on, I was mainly concerned about the flaky stuff.

Rear stripped. Unfortunately, the stock rear struts were even harder to remove because the spring forces the strut into the driveshaft boot and is very easy to tear. I was able to pry the left side out okay, but the right side ended up making a 1cm tear in my new boot which I sealed with RTV and hope it holds. Again, spring compressors would make this a much easier and safer removal.

FR side stripped. Someone was rubbing tires pretty good on the front sides under prior ownership.

How's that for weight reduction? :biggrin: Maybe one half of the ancient dirt and coating removed.

Setting up fender liners for repainting after degreasing, scuffing, washing, and drying off.

Few coats of trim paint on either side.

I like this paint a lot. Used it on my daily's windshield cowl which has been sitting in the sun for 2-3 years now and it still looks as good as new, unlike the rest of the car. This should be practically a permanent fix for these fender liners. There are some cheap aftermarket replacements I've read about that can also work but I didn't want to bother.

My little mini-paint booth setup for applying the undercoating without overspray going everywhere, worked great but the Rustoleum professional undercoating doesn't seem to generate much overspray anyways.

RL completed. The stuff lays down very well and is easy to spray. I had bought a few cans of black Plasti-dip for the coating, but I decided to buy true undercoating at the last minute and read good things about the Rustoleum Professional (vs. the basic one, not sure of the difference). Part of my personal vendetta against Plasti-dip I guess.

FL coated. The front is harder than the rear since the suspension components are in the way of most of it.

FR coated.

Finally, the coilovers are starting to go in. Spring preload adjusted, heights measured and adjusted vs. the stock struts, and bolted in with the bottom bushing torqued under load.

Nice picture of the rear installed with the "new" fender liners.

Front all put together again. Predictably a few fender liner clips were already broken or of the wrong type, so I re-used the good ones and replaced the more visible ones on the outside with new clips. They're actually just these stupid cheap ones I bought off eBay last year, but the fitment is perfect and I would absolutely use them again. (

https://www.ebay.com/itm/100x-FENDE...HONDA-CIVIC-ACCORD-ACURA-INTEGRA/254311632838).

Before picture of the same side in case you forgot.

Another view. One day I'll also clean up the suspension pieces to make the whole area look factory(ish) fresh.

Other side installed. I still need to fix up the front A/C duct area a bit but otherwise, I'd say it turned out very well. I spent some time shimmying the fender liner around to make sure there weren't any gaps between it and the fender like before.

One more view.

Here's test 1 of the new ride height with ~2 1/2" of drop compared to the stock strut length. The rears are just about where I'd like them but the front is a bit high.

Front view. A bit too high, or so I thought.

Height is pretty easy to adjust just by removing the bottom strut bushing bolt and rotating the bottom of the strut. This is test 3 after messing with the front height a few times, and this is how I have it now.

Unfortunately and predictably, the car was very hard to get off the lift without scraping the front lip, unlike before where I could just drive straight on and off. I can still make it (gingerly) up the garage ramp and my driveway, but I already scraped the lip on a dip entering a parking garage which I'll have to fix up, name of the game I guess. I'm going to raise the front by maybe another 1/2" especially after the coils settle a bit, which should give me a nice and useable fitment while reducing the chance I scrape up the bottom sides. I can see why people use air suspension now but I want to avoid it if I can.

After a well-deserved wash and drive home. The EBC yellows still dust like crazy, on the plus side it makes washing the wheels more satisfying but I'll just go with the EBC reds next time.

Big fan of how the rear is sitting, the front is about where I'd like it visually but I'll have to raise it a bit more to get some drivability back.

Side

Last one.

First impressions of the Fortune Auto 500's is very good, with the two downsides being that I had to use spacer washers on the rear since the lower bushing was too narrow to fit snug in the knuckle and they didn't send brake hose bracket adapters for the front struts, so I'll have to install them when they arrive in a few weeks. Otherwise, they ride fantastically, actually a bit better than the stock struts on the street, I had them on the softest setting and they absorbed bumps better and rode smoother than stock. It was a bit too soft so I turned them up a few clicks. Not many miles on them but so far I'm very impressed.

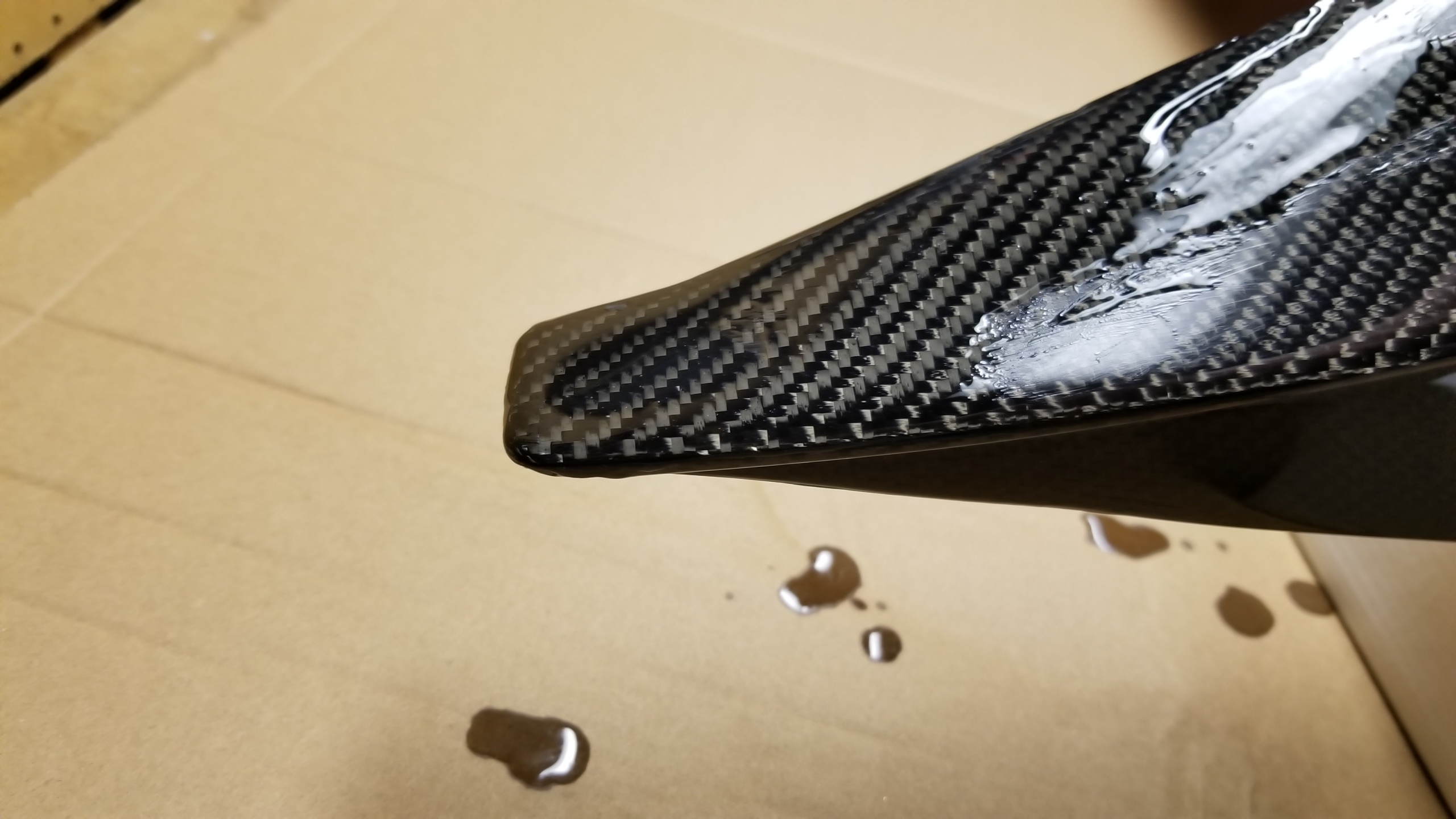

I'm working on ceramic coating the new wheels and putting the center caps & Advan stickers on. Still not sure how I feel about the Muteki lug nuts, I think there's a bit too much going on with the stock Advan blue valve stem and eventual blue RGIII sticker, and the locking nut is a different shade than the rest for some reason. Maybe just long black lugs or shell out for the Kicks R40 after all? I'm sure the black would look good with the black center caps.

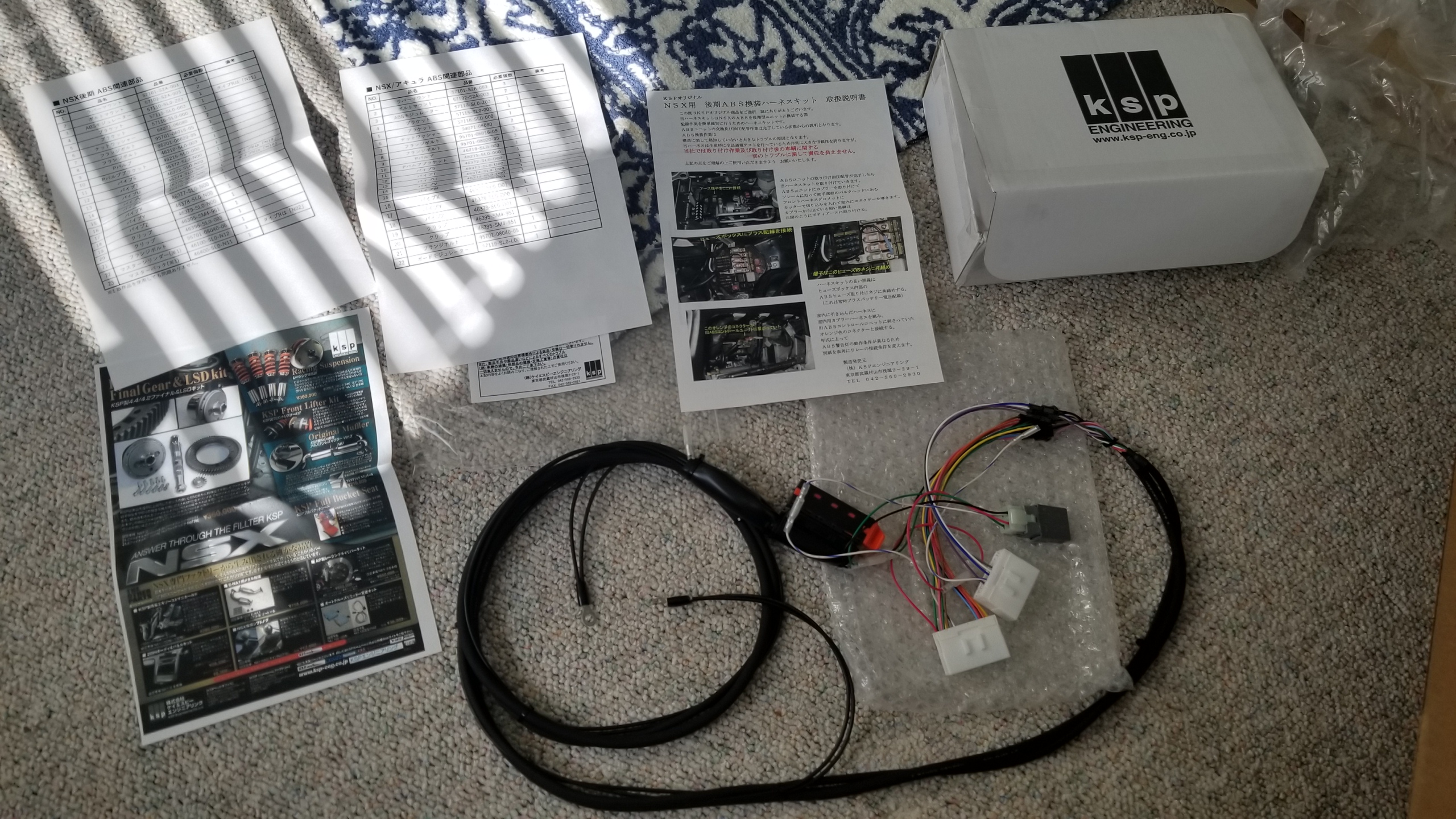

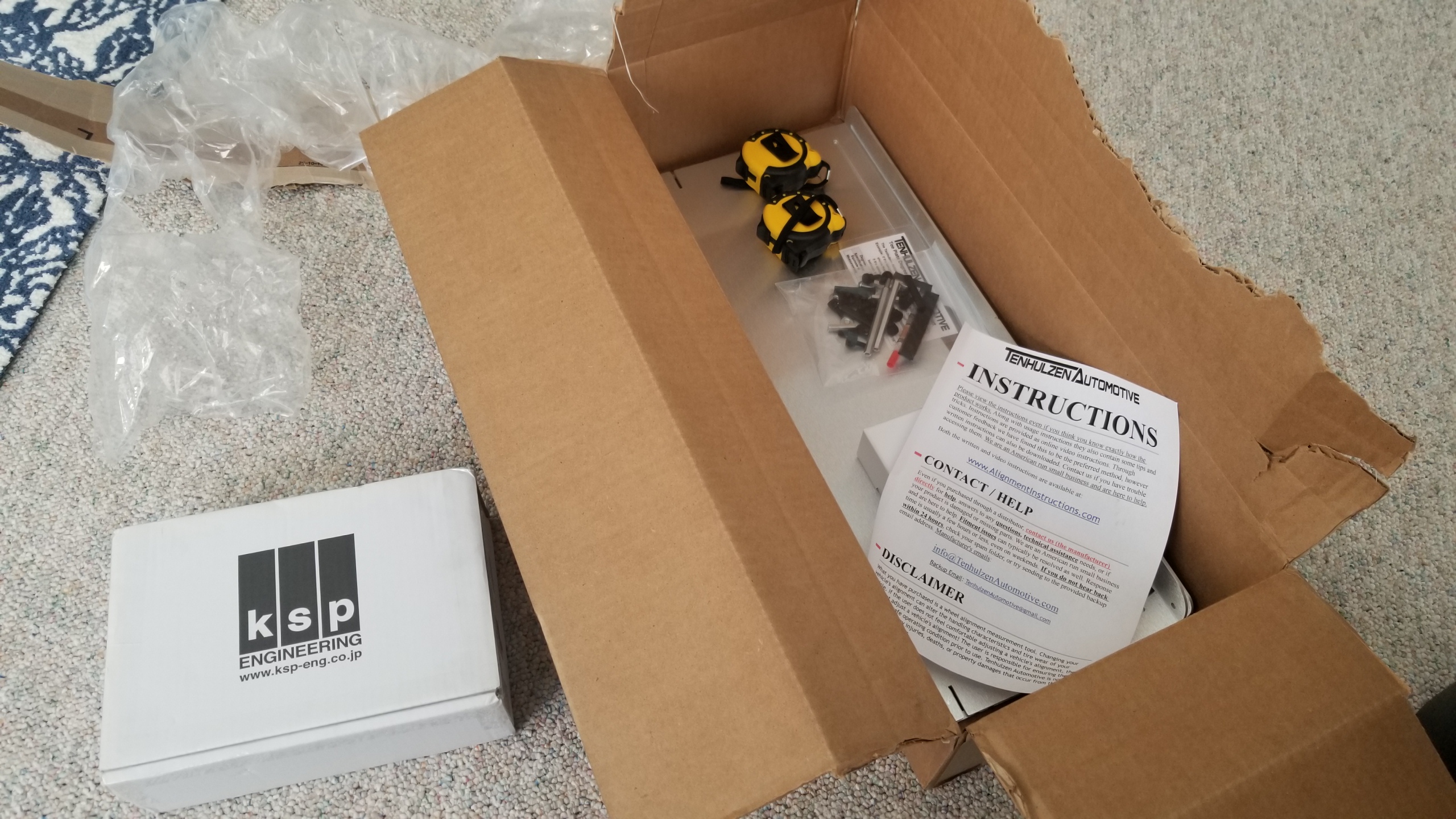

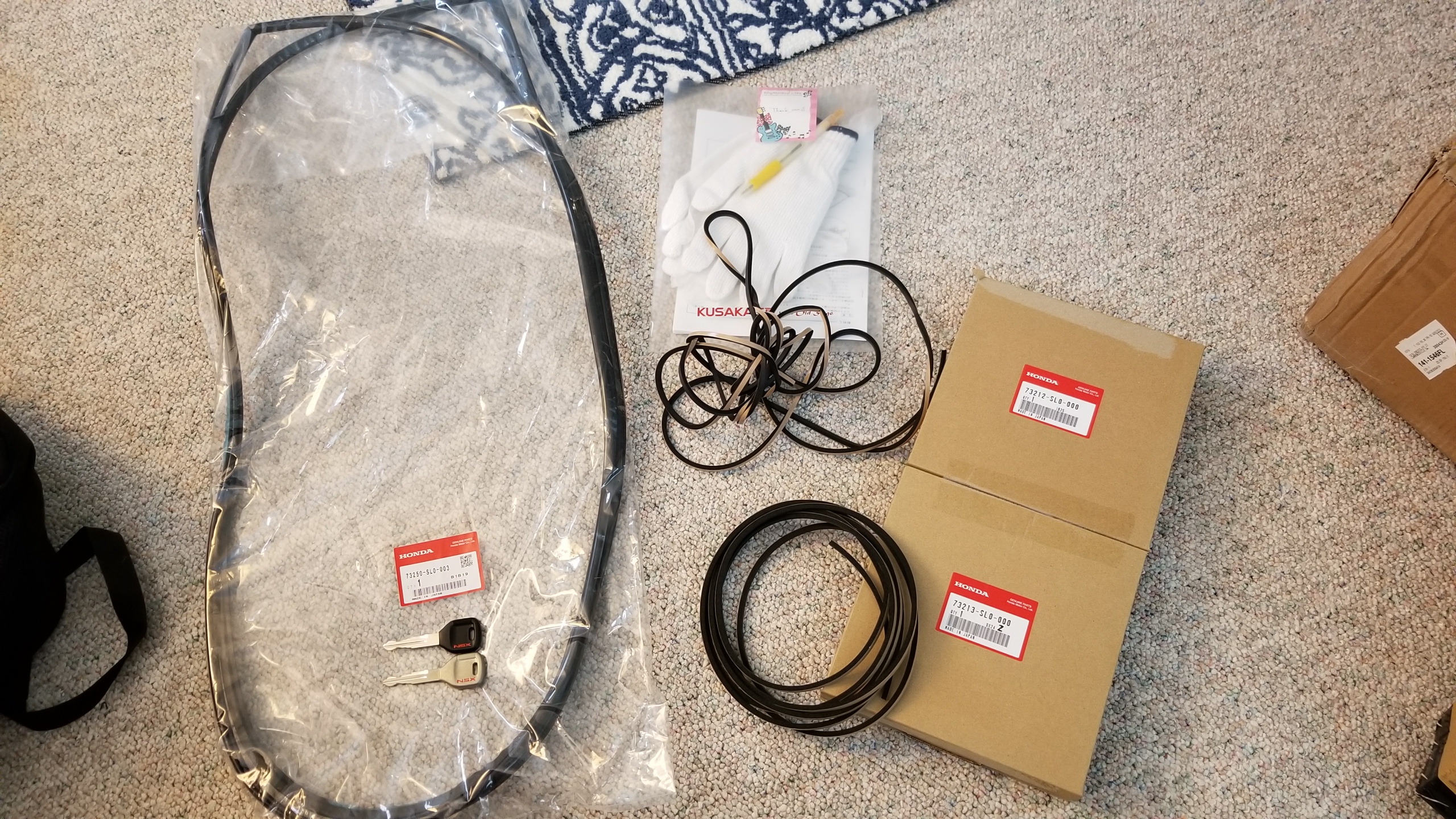

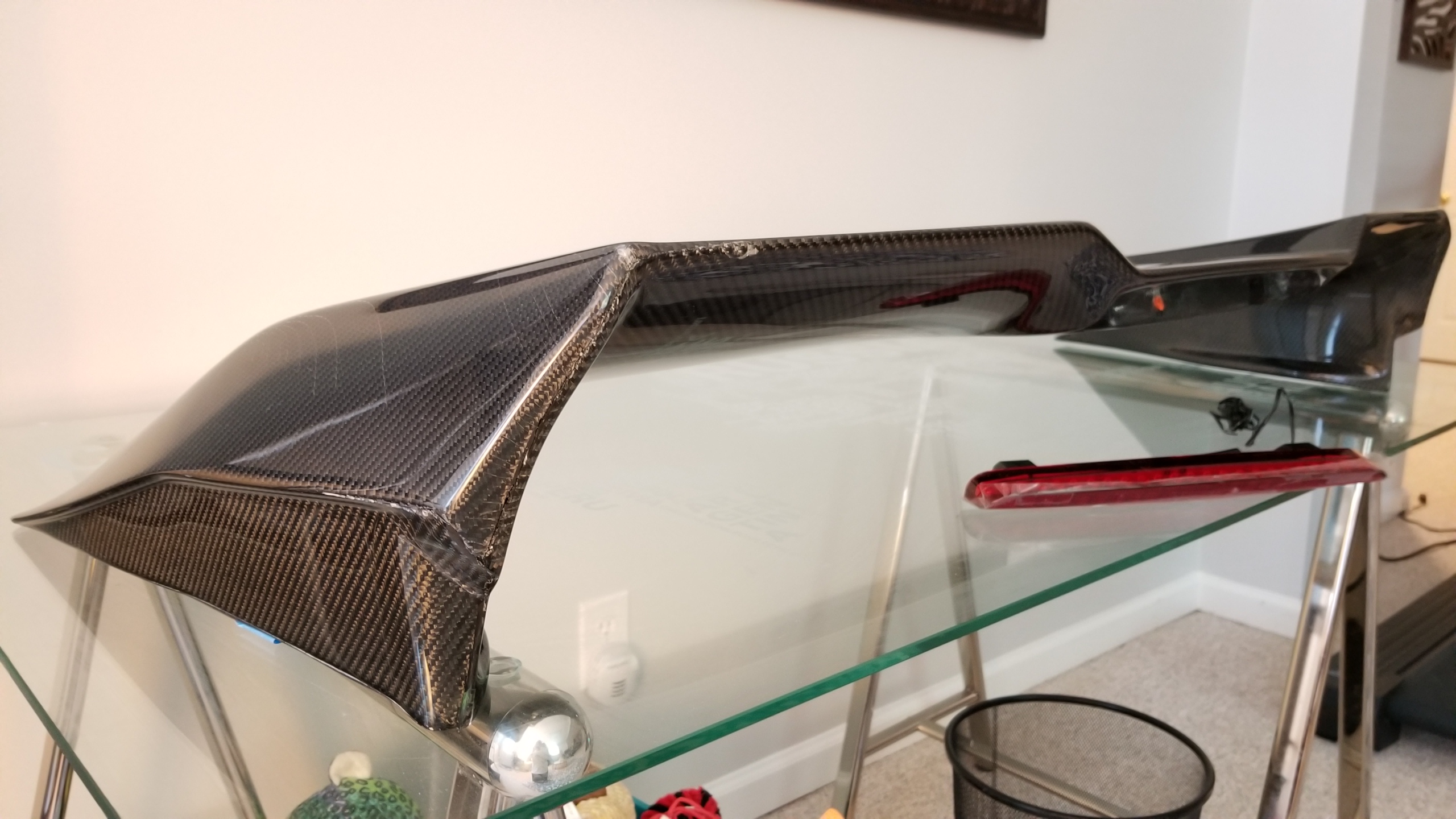

Otherwise I'm the prep on the interior trim pieces, and after that I should be getting a bunch of minor parts to swap out and then begin the ABS conversion.

Oh yeah, and I'd still need to get another alignment once I get my strut lengths dialed in. I haven't measured it yet but I'm sure the rear camber is way negative, and I don't want to kill tires that quickly. I might buy a DIY alignment kit and try it out myself before I go to a shop again, especially since I'm expecting my camber bolts will be maxed out positive in the rear and I'd need to install eccentric bushings or similar to get back to sane camber...we'll see.